Method for preparing 2, 6-diisopropylnaphthalene through naphthalene shape-selective alkylation

A technology of diisopropylnaphthalene and alkylation, applied in chemical instruments and methods, organic chemistry, chemical recovery and other directions, can solve the problems of low conversion rate and selectivity of 2,6-DIPN, and achieve convenient operation and low cost. Inexpensive and simple to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0041] Preparation Example 1 Catalyst Preparation

[0042] Take 10 g of MOR molecular sieve (Si / Al=19) and place it in a tube furnace, heat up to 500°C under nitrogen protection, stop feeding nitrogen, inject 25% ammonia water, and feed 50 g / h, and after 60 min of treatment, The feed was switched to nitrogen purging for 30 min to cool down. The resulting catalyst was named MOR(19)-500-60.

preparation example 2~8

[0043] Preparation Examples 2-8 Catalyst Preparation

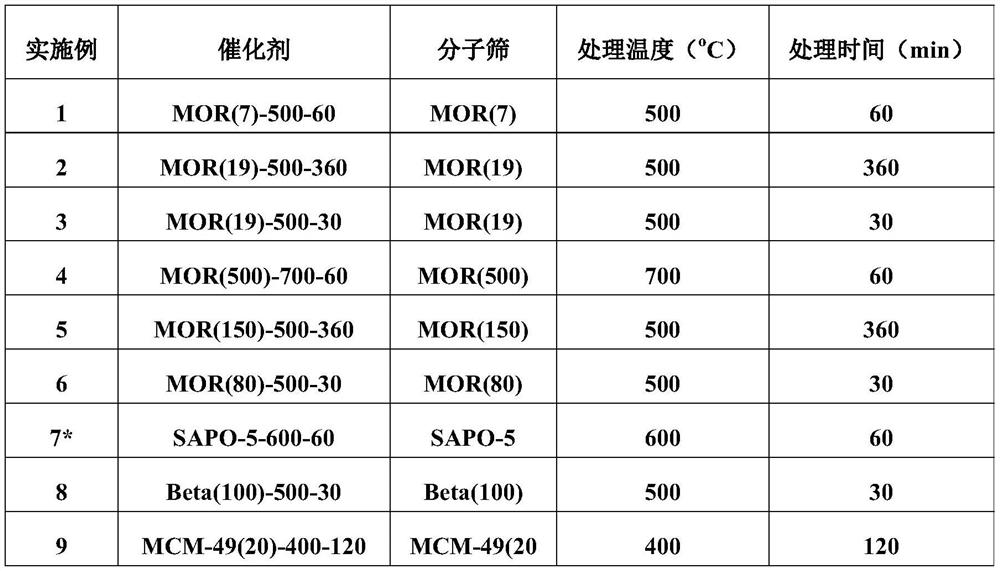

[0044] The operation steps are the same as those of Preparation Example 1, the types of molecular sieves, and the treatment temperature and time are shown in Table 1.

[0045] Table 1 Preparation conditions table of catalysts

[0046]

[0047] Note: *Si / (Si+Al+P)=0.20 in SAPO-5

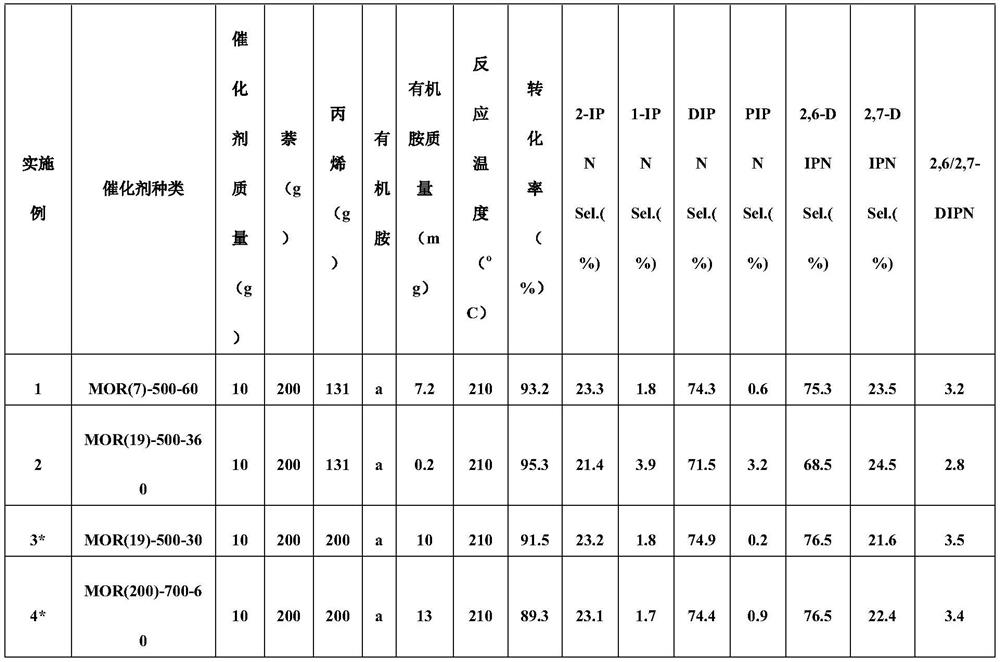

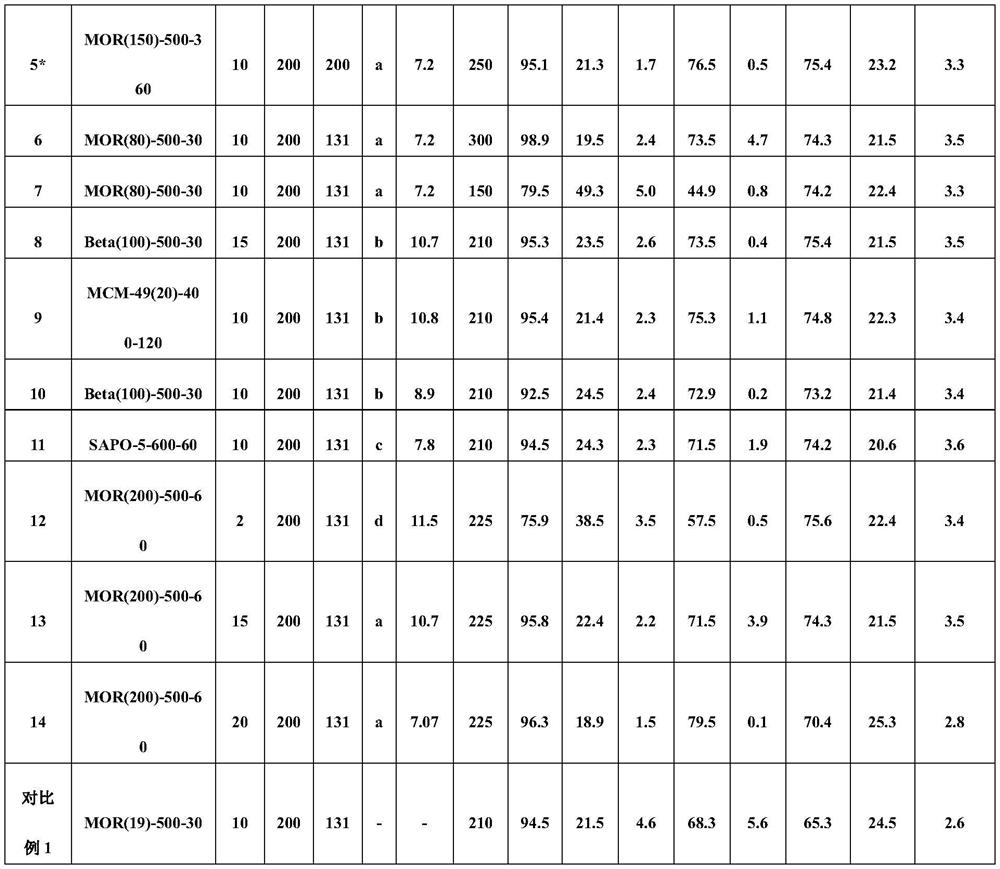

[0048] Evaluation of the reaction performance of the catalysts of Examples 1-18

[0049] A 500mL reaction kettle was used for evaluation. 10 g of the catalyst was loaded into a tube furnace, activated under the protection of inert gas nitrogen at 500° C. for 240 min, and then lowered to room temperature. The catalyst was taken out and put into the reaction kettle, 200 g of industrial naphthalene and 7.91 mg of 1,3,5-trimethylpyridine were added, and the mixture was stirred evenly, replaced with inert gas nitrogen three times, and the reaction kettle was sealed. 131 g of propylene was injected using a high pressure pump. The temperature was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com