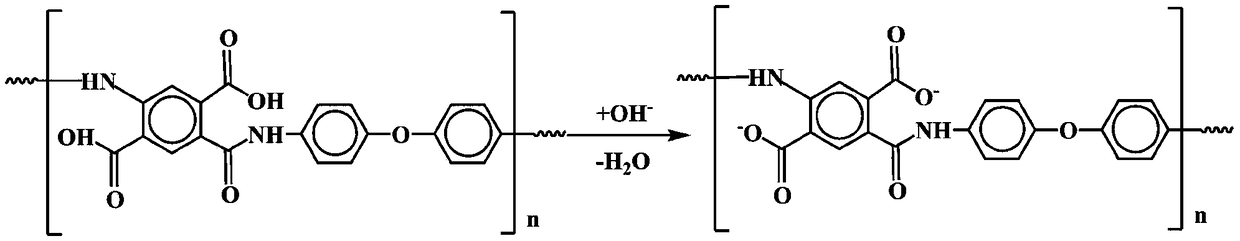

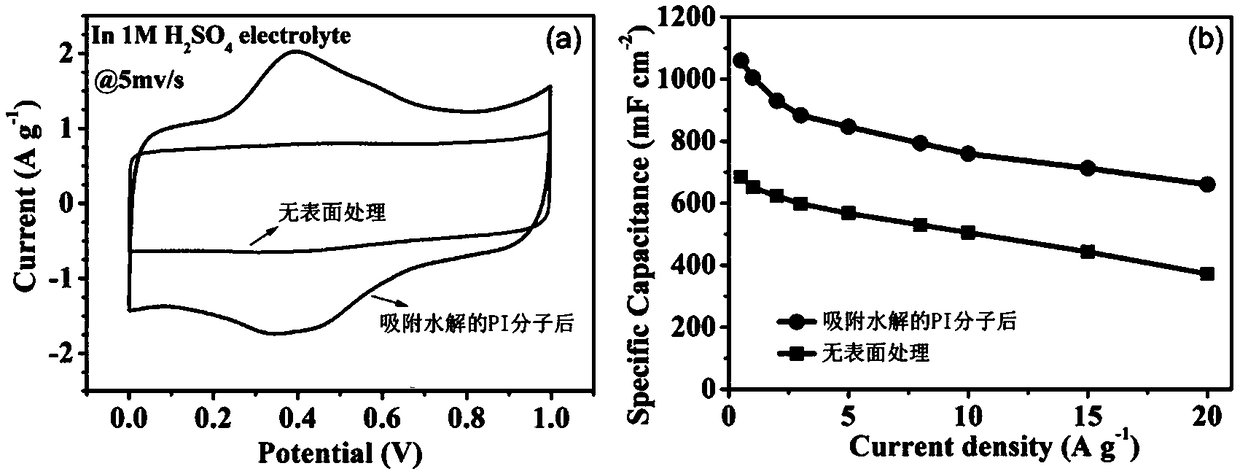

A method of adsorbing and hydrolyzing polyimide molecules on graphene surface to improve specific capacitance

A graphene surface, polyimide technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of narrow voltage window, decreased specific capacitance, short cycle life, etc., to increase the pseudocapacitance component , the effect of cheap raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further below in conjunction with example, but the present invention is not limited to specific embodiment.

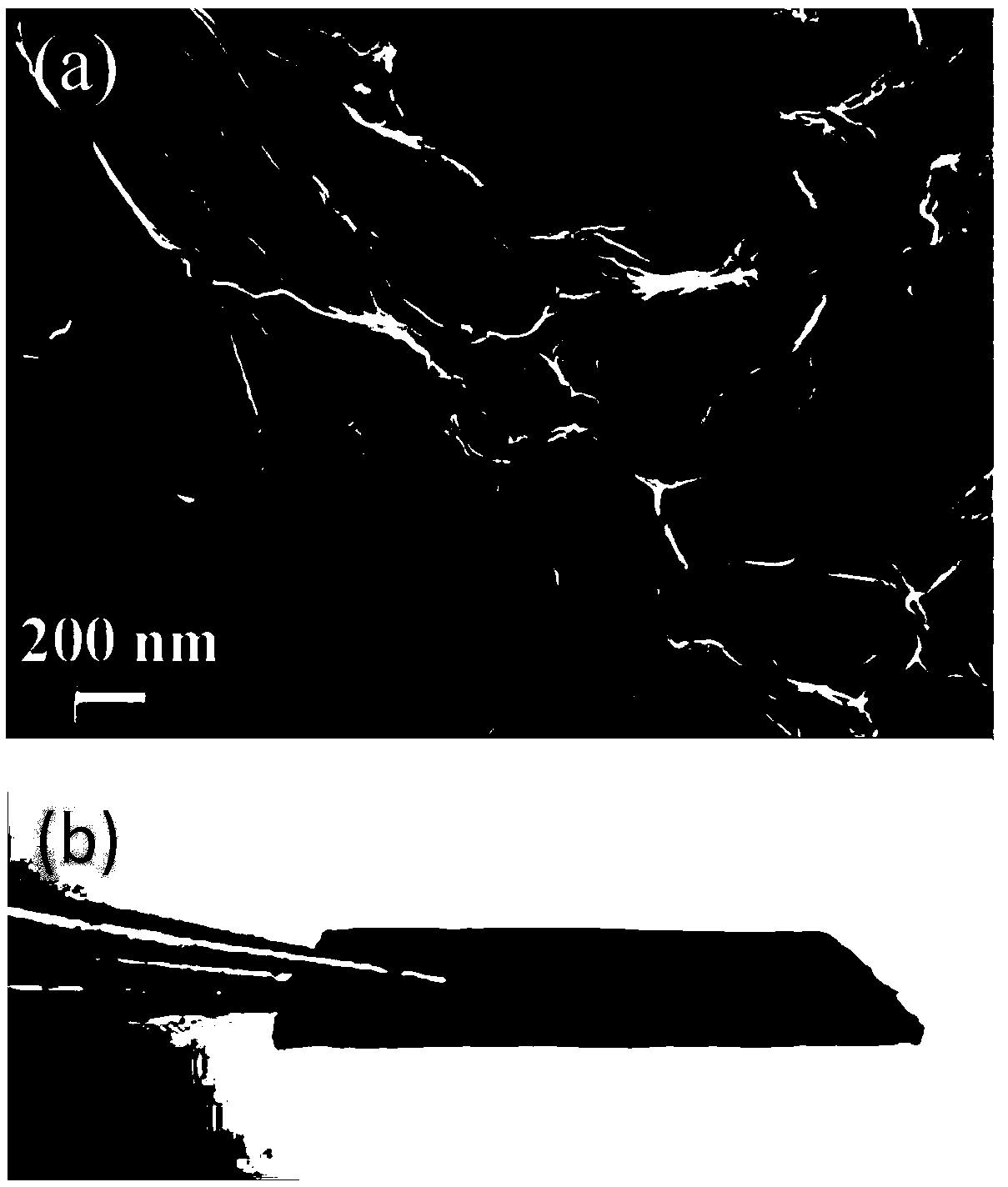

[0022] (1) Utilize improved Hummer's method, use expanded graphite powder as raw material, prepare graphene oxide. After being dispersed in deionized water and concentrated by high-speed centrifugation, it is sealed and left standing, and stored at room temperature in the dark for 7 to 15 days to obtain liquid crystal graphene oxide.

[0023] (2) Measure 20ml of liquid crystal graphene oxide viscous solution with a concentration of 9.0mg / ml and place it in a 100mL beaker, then add sodium chloride and ammonium carbonate, 588mg each, and add deionized water to stir and dissolve to obtain graphene oxide A mixed solution with a concentration of 6mg / mL. After 5 hours of magnetic stirring, it was left to stand for 3 to 5 days to obtain a uniform and stable liquid crystal graphene oxide / sodium chloride / ammonium carbonate (or ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com