A steam channeling plugging method for heavy oil thermal recovery horizontal wells

A technology for thermal recovery of heavy oil and horizontal wells, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc. It can solve problems such as failure to complete according to design requirements, easy to be pushed into deep formations, low viscosity of high temperature resistant plugging agents, etc. , to achieve the effect of improving the resident performance, improving the resident performance, and enhancing the plugging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Steam Channeling Plugging Method for Thermal Recovery Horizontal Well

[0033] Proceed as follows:

[0034] (1) Lower the steam injection pipe string into the oil layer, adopt the general injection method, and inject steam to preheat the formation; the amount of steam injected is 300-600t;

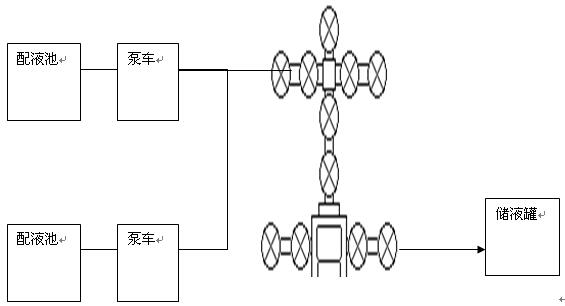

[0035] (2) Inject high-viscosity jelly to assist the resident slug, and the injection volume is 50-100m 3 , the injection speed is 10~20m 3 / h;

[0036] (3) Inject low-viscosity silicon salt high-temperature plugging agent to block the slug, and the injection volume is 80-200m 3 , the injection speed is 20~30m 3 / h;

[0037] (4) Repeat steps (2) and (3) (that is, alternately inject high-viscosity jelly and silicon salt high-temperature plugging agent) until the injection pressure requirement of the construction design is reached, and stop the injection;

[0038] (5) Inject steam to heat the plugging agent to promote the solidification or gelation of the plugging age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com