Ionic POSS-containing block copolymer composite proton exchange membrane and preparation method thereof

A technology of block copolymer and proton exchange membrane, which is applied in the field of ionic POSS-containing block copolymer composite proton exchange membrane and its preparation, can solve the problems of low proton conductivity, easy swelling, dimensional instability, etc. The method is simple, time-consuming, and the effect of improving proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Spread a 50% sulfonated polysulfone solution dissolved in N,N-dimethylformamide with a concentration of 0.3g / mL on a glass plate, and then put it into the toluene solution and let it stand until After 30 minutes, the membrane on the glass plate turns white completely, and a porous 50% sulfonated polysulfone matrix membrane is obtained;

[0057] (2) Immediately after the porous membrane on the glass plate in step (1) is immersed in a concentration of 0.05g / mL toluene dissolved block ratio: PMMA: POSS-(PMMA-PS) of PS=1:7 8 Block ratio: PMMA:PS=1:7 solution, let it stand for about 10min;

[0058] (3) Put the composite porous membrane obtained in step (2) into an oven at 80° C. for 10-12 hours to dry, and then peel off the membrane on the glass plate to obtain a composite proton exchange membrane.

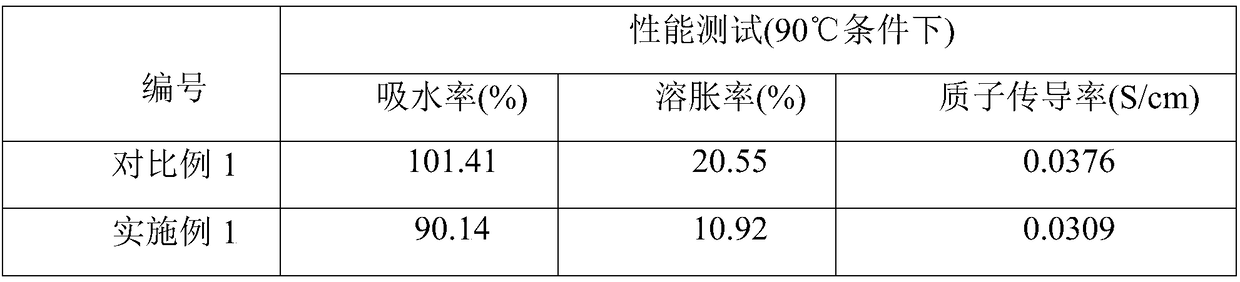

[0059] The performance test comparative data of table 1 embodiment 1 and comparative example 1

[0060]

Embodiment 2

[0062] (1) Spread 60% sulfonated polysulfone solution dissolved in N,N-dimethylformamide with a concentration of 0.3g / mL on a glass plate, and then put it in toluene solution and let it stand for 25min Until the membrane on the glass plate turns white completely, a porous 60% sulfonated polysulfone matrix membrane is obtained;

[0063] (2) Immediately afterwards, immerse the porous membrane on the glass plate in step (1) with a concentration of 0.05g / mL in the POSS-PMMA-PS solution dissolved in toluene, and let it stand for about 15min;

[0064] (3) Put the composite porous membrane obtained in step (2) into an oven at 80° C. for 10-12 hours to dry, and then peel off the membrane on the glass plate to obtain a composite proton exchange membrane.

Embodiment 3

[0066] (1) Spread a 50% sulfonated polysulfone solution with a concentration of 0.3 g / mL dissolved in a mixed solvent of N,N-dimethylformamide and toluene (volume ratio 9 / 1) on a glass plate Then put it into the toluene solution and let it stand for 30min until the membrane on the glass plate turns white completely to obtain a porous 50% sulfonated polysulfone matrix membrane;

[0067] (2) Immediately afterwards, the porous membrane on the glass plate in step (1) is immersed in toluene to dissolve the concentration of 0.05g / mL block ratio: PMMA:PS=1:4 POSS-(PMMA-PS) 8 In the solution, let it stand for about 10 minutes;

[0068] (3) Put the composite porous membrane obtained in step (2) into an oven at 80° C. for 10-12 hours to dry, and then peel off the membrane on the glass plate to obtain a composite proton exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com