Box-packed bean curd and preparation method thereof

A tofu and box-packing technology, which is applied in the field of tofu preparation, can solve the problems of being easy to break and difficult to cook, and achieve the effects of not breaking easily, improving production efficiency, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

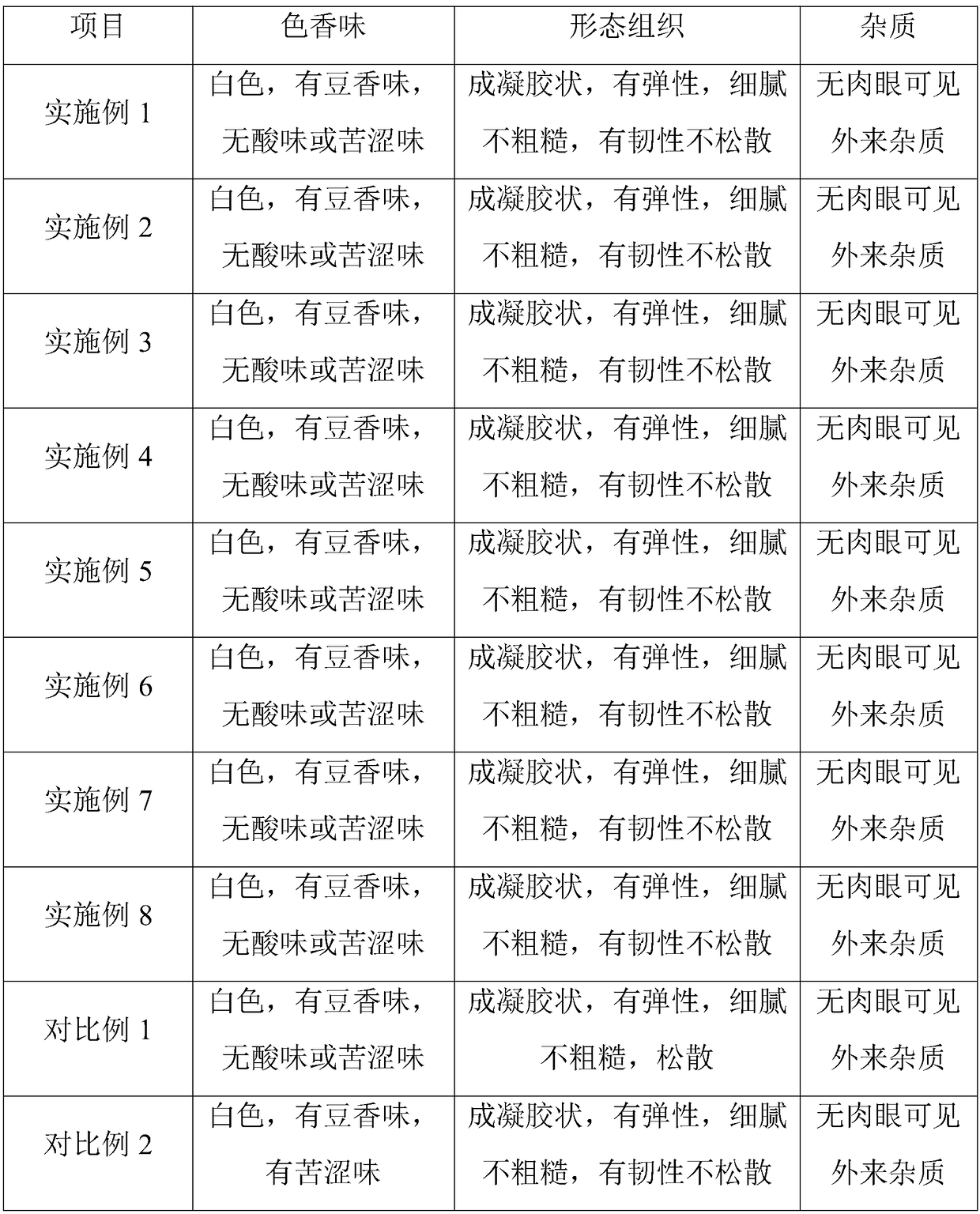

Examples

preparation example Construction

[0024] The boxed tofu preparation method of an embodiment of the present invention comprises the following steps:

[0025] Mixing slurry, mixing the cooked slurry cooled to below 40°C with the aqueous solution of the compound coagulant to prepare the mixed slurry;

[0026] Filling, filling and sealing the mixed slurry in a packaging container to obtain a boxed mixed slurry;

[0027] Sterilize and set the shape, place the boxed mixed pulp in water at 77°C to 86°C for 20min to 30min to sterilize and set the shape to obtain boxed tofu;

[0028] Wherein, the compound coagulant includes the following raw materials in parts by weight: 40-60 parts by weight of glucono-δ-lactone, 10-30 parts by weight of calcium sulfate, 1.0-5.0 parts by weight of magnesium chloride and 1.0-8.0 parts by weight Food thickener in parts by weight; in the aqueous solution of the compound coagulant, the weight ratio of the compound coagulant to water is 1:1˜1:5.

[0029] In the above-mentioned preparatio...

Embodiment 1

[0041]Boil the pulp, close the pulp release valve before pumping in the raw pulp, and confirm that the concentration of the soy milk is 10 degrees when pumping the pulp (the concentration of the raw pulp is half a degree higher than the specified cooked pulp, if the concentration is higher than the specified concentration, you need to add water to adjust to the specified concentration). The steam valve can only be opened to burn the slurry when the slurry level exceeds the steam pipeline by 20cm, and the slurry pumping is stopped when the slurry level is 60cm away from the barrel mouth. When burning pulp, when the foam liquid level is close to the mouth of the barrel, close the steam valve and add defoamer. When adding the defoamer, add the defoamer in batches with a fixed container of 10-15 grams, sprinkle the defoamer evenly into the tank and stir. The foamy surface of the soy milk needs to be cooked for 3 to 4 times in a row before disappearing. After the foam disappears, c...

Embodiment 2

[0049] The difference between Example 2 and Example 1 is that immediately after the pulping is completed, the aqueous solution of the compound coagulant is added to the water cooled to below 40°C according to the weight ratio of the cooked pulp and the aqueous solution of the compound coagulant in a ratio of 80:1. into the cooked pulp and mix well.

[0050] Among them, the aqueous solution of the compound coagulant is to add 1.0g propylene glycol alginate to 52g water and mix, then add 40g glucono-δ-lactone, 10g calcium sulfate and 1.0g magnesium chloride to mix, and filter to obtain the aqueous solution of the compound coagulant .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com