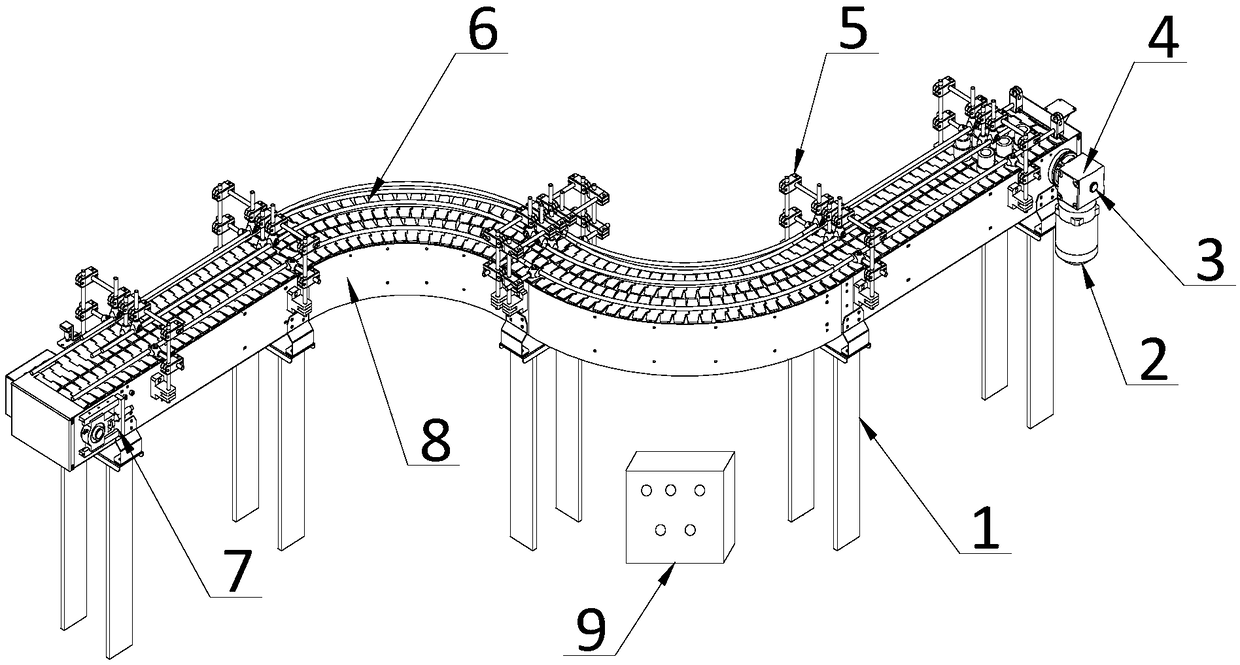

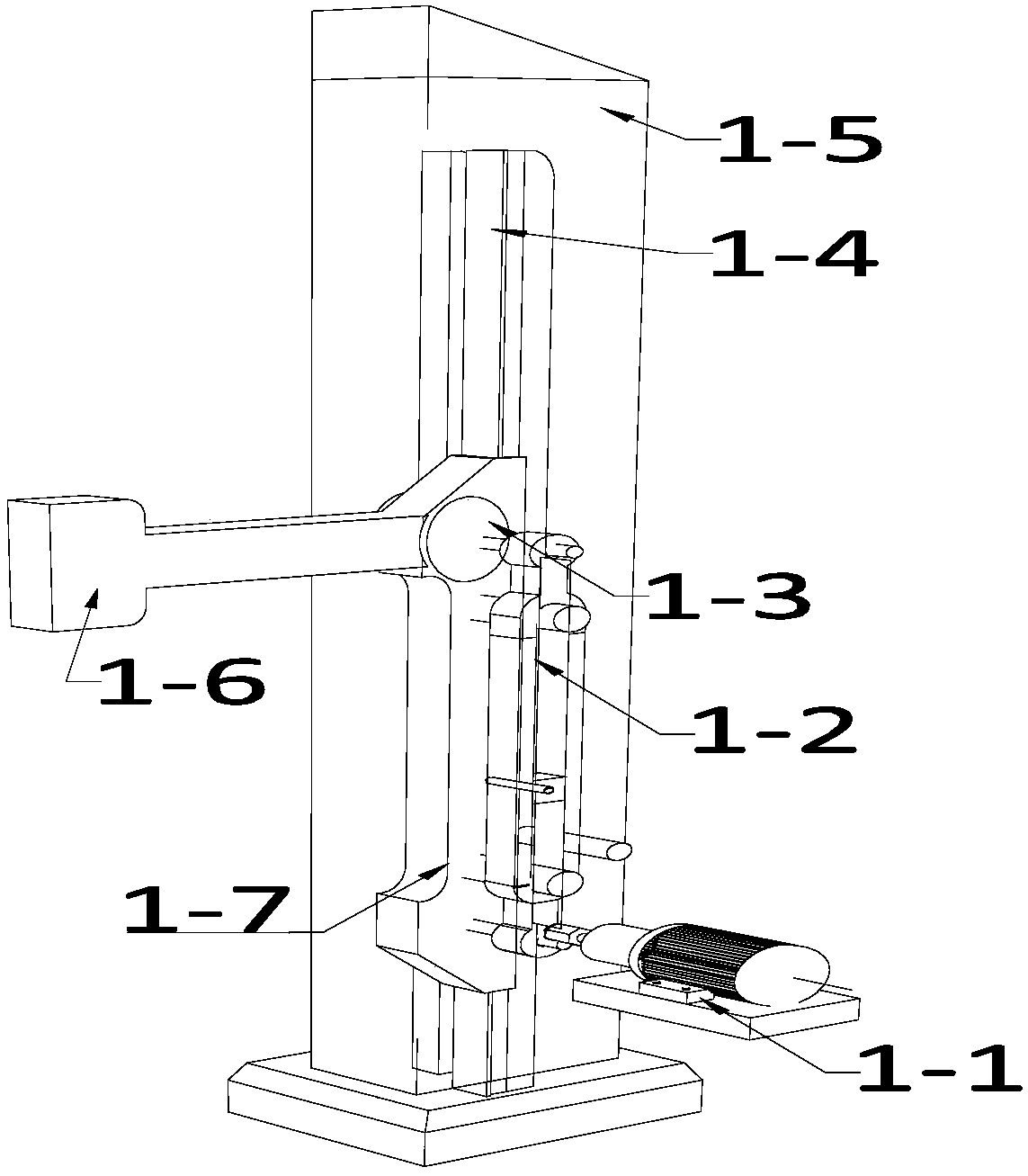

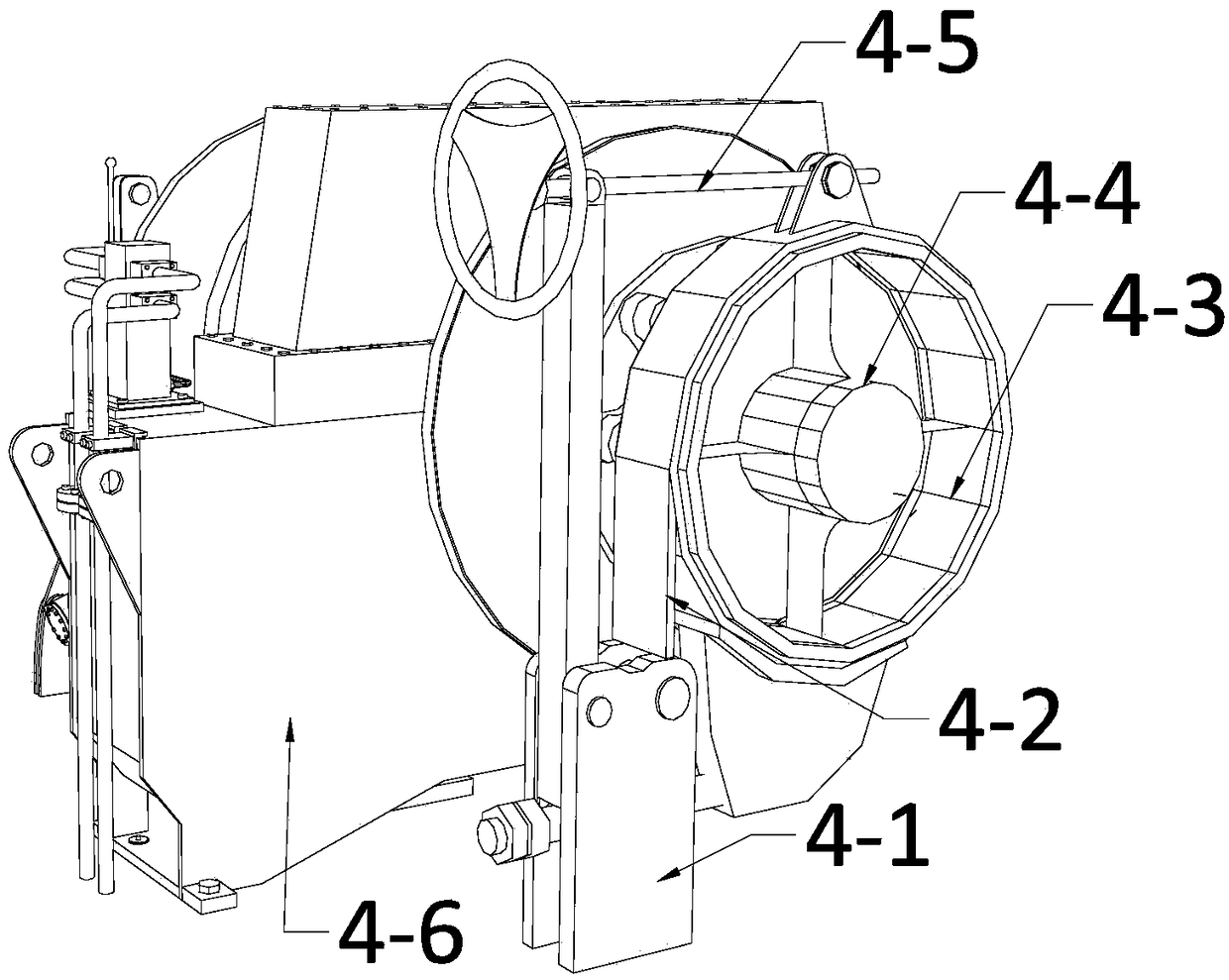

Conveying belt system in Tetra Fino Aseptic fresh milk packaging machine

A technology for packaging machines and conveyor belts, applied in the field of conveyor belt systems, can solve the problems of easy slipping of conveyor belts, large occupation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Manufacture the buffer rod 6-5-3 of the present invention according to the following steps, and by mass percentage:

[0055] Step 1: According to the mass percentage, add 2% of N-methyl-N-(trimethylsilyl)-2,2,2-trifluoroacetamide in the proportioning components to the three-pot series stirring reaction In the tank, add 3% of purified lake water at the same time, start the stirrer in the three kettle series stirred reactor tank, and set the rotating speed to be 5rpm;

[0056] Step 2: After running the three-tank stirred reactor in series for 3 minutes, add 7% CSA coagulation accelerator admixture and 4,4-[(1-methylethylene)bis(4,1-phenylene oxide )] diphenylamine 4%, start the steam conduction heater in the three still series stirred reactor tank, make the temperature rise to 7 ℃, add promotor DPG 3% and strontium nanoparticle 9%, in the three still series stirred type reaction Stir evenly in the tank to obtain component I homogenate;

[0057] The 3rd step: take by wei...

Embodiment 2

[0059] Manufacture the buffer rod 6-5-3 of the present invention according to the following steps, and by mass percentage:

[0060] Step 1: According to the mass percentage, add 11% of N-methyl-N-(trimethylsilyl)-2,2,2-trifluoroacetamide in the proportioning components to the three-pot series stirring reaction In the tank, add 13% of purified lake water simultaneously, start the stirrer in the three kettle series stirred reactor tank, and set the rotating speed to be 50rpm;

[0061] Step 2: After 13 minutes of running the three-tank stirred reactor in series, add 85% CSA coagulation accelerator admixture and 4,4-[(1-methylethylene)bis(4,1-phenylene oxide )] diphenylamine 95%, start the steam conduction heater in the three still series stirred reactor tank, make the temperature rise to 85 ℃, add promotor DPG 39% and strontium nanoparticle 19%, in the three still connected stirred type reaction Stir evenly in the tank to obtain component I homogenate;

[0062] The 3rd step: ta...

Embodiment 3

[0066] The buffer rods 6-5-3 prepared in Examples 1-2 were compared with the same parts obtained in the comparative example. The heat distortion temperature, compressive strength, bending stiffness, and corrosion rate of the two were counted, and the results are shown in Table 1.

[0067]

[0068] It can be seen from Table 1 that the buffer rod 6-5-3 of the present invention has the above-mentioned performance indicators better than the products produced in the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com