Method for preparing graphene composite based on combustion synthesis reaction

A composite material, combustion synthesis technology, applied in the direction of graphene, chemical instruments and methods, anti-corrosion coatings, etc., can solve the problems of difficult scale promotion, complicated operation, high equipment requirements, etc., to achieve optimized production process, simple operation, The effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

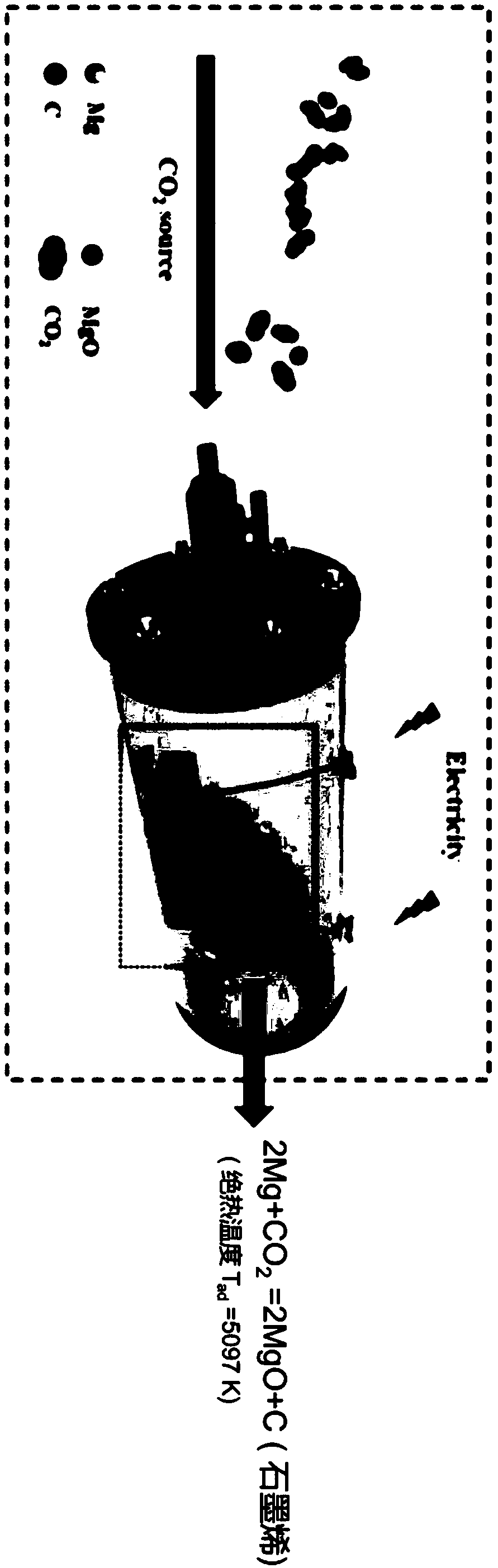

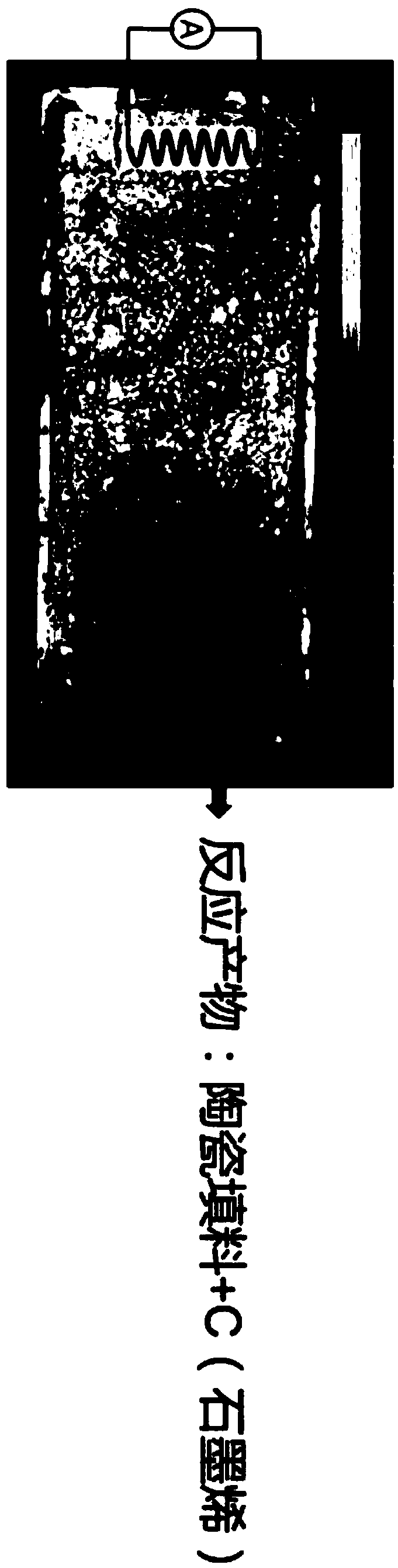

[0052] The graphene composite material preparation method of embodiment 1 is as follows:

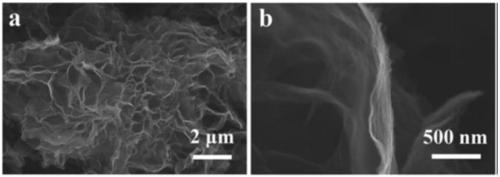

[0053] Select magnesium powder with an average particle size of 100 microns and alumina powder of 200 nanometers and mix them in a ball mill jar for 1 hour. The mass ratio of alumina powder to magnesium powder is 4:1 (i.e. M=4). The raw material powder is placed in the graphite grinding tool of the reaction device. In the carbon dioxide gas of 0.5MPa, the 50A tungsten wire coil is energized to induce the magnesium powder in the raw material and carbon dioxide to undergo a self-propagating combustion reaction (5097K, 40min). After the device is cooled, Obtain gray-black graphene composite powder. attached figure 1 It is a schematic diagram of the reaction principle of the preparation method. attached figure 2 is a schematic diagram of the reaction products.

Embodiment 2

[0055] In the preparation method of the graphene composite material in Example 2, the mass ratio of alumina powder to magnesium powder is controlled to be 5:1 (ie M=5), and the rest are the same as in Example 1.

Embodiment 3

[0057] In the preparation method of the graphene composite material in Example 3, the mass ratio of alumina powder to magnesium powder is controlled to be 6:1 (ie M=6), and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com