Method for preparing tremelliform porous carbon through waste sugar solution, and application of porous carbon in preparing electrode plate

A technology for preparing electrodes and porous carbon, which is applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., and can solve problems such as environmental pollution and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

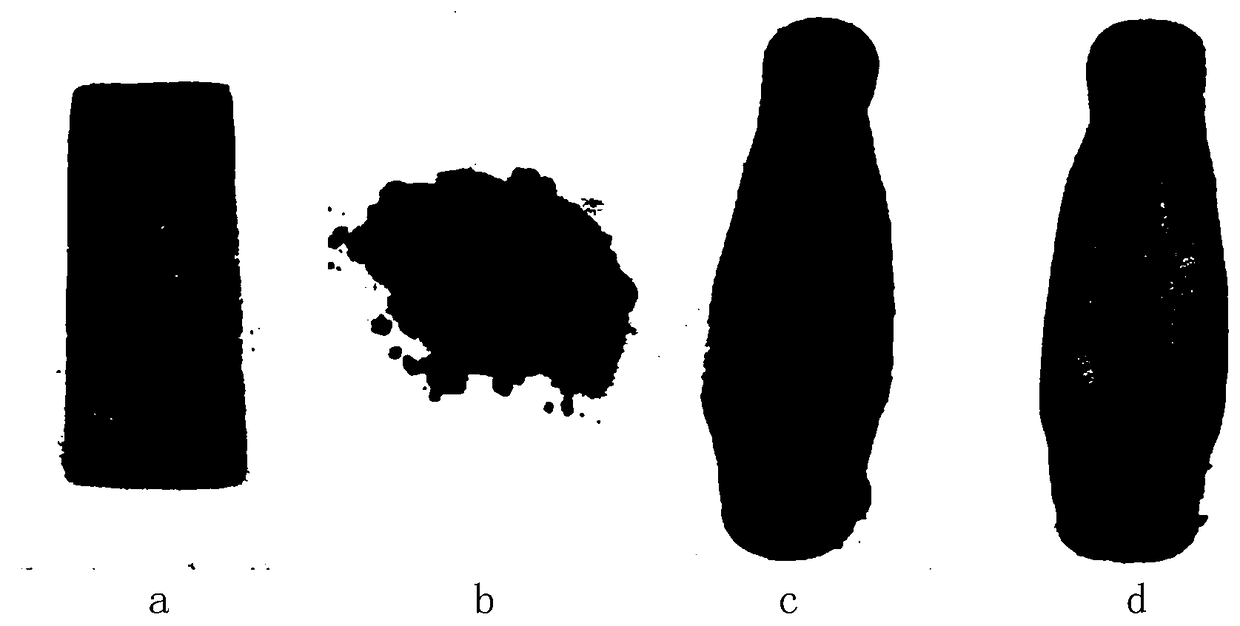

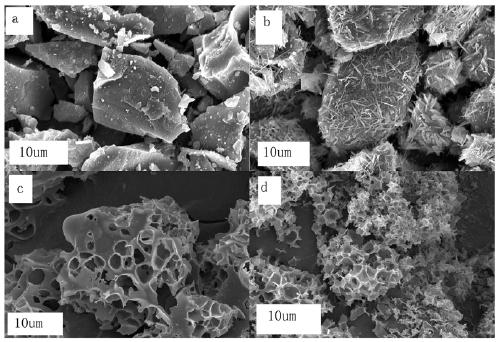

[0028] Example 1 Mixed carbonization / activation of waste sugar liquid and lignin to prepare white fungus-like porous carbon.

[0029] Step 1, the waste sugar solution is filtered under reduced pressure to remove insoluble impurities, and then 5g of waste sugar solution and 1g of lignin are mixed (m 废糖液 / m 木质素 =5 / 1), mechanically stirred for 2 h.

[0030] The mixture obtained above is poured into a beaker, and put into a blast drying oven, at 90 o At the temperature of C, after keeping for 12 hours, the dried product was obtained and placed in a tube furnace for high-temperature carbonization treatment: 700 o High-temperature carbonization at C temperature for 2 h, and a fluffy carbonized sample was obtained.

[0031] Step 2, chemical activation to prepare tremella-like porous carbon:

[0032] (1) Mix the carbonized sample and KOH in step 1 according to the mass ratio: m KOH / m 炭材料 =1.

[0033] (2) The mixture of carbonized sample and KOH was placed in a tube furnace, an...

Embodiment 2

[0037] Example 2 is basically the same as Example 1, except that the mass ratio of the waste sugar solution and lignin described in step 1 is 5 / 2, the mechanical stirring time is 1 h, and the carbonization temperature is 500 o C, the carbonization time is 1h. The activation temperature described in step 2 is 500 o C, the activation time is 1h, m KOH / m 炭材料 =2.

Embodiment 3

[0038] Example 3 is basically the same as Example 1, except that the mass ratio of the waste sugar solution and lignin described in step 1 is 5 / 3, the mechanical stirring time is 3 h, and the carbonization temperature is 600 o C, the carbonization time is 3h. The activation temperature described in step 2 is 600 o C, the activation time is 2.5 h, m KOH / m 炭材料 =4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com