Production process of sodium metabisulfite

A technology of sodium metabisulfite and production process, which is applied in the preparation of alkali metal sulfites, alkali metal sulfites/sulfites, chemical industry, etc., to achieve the effects of improving atom economy, saving resources and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

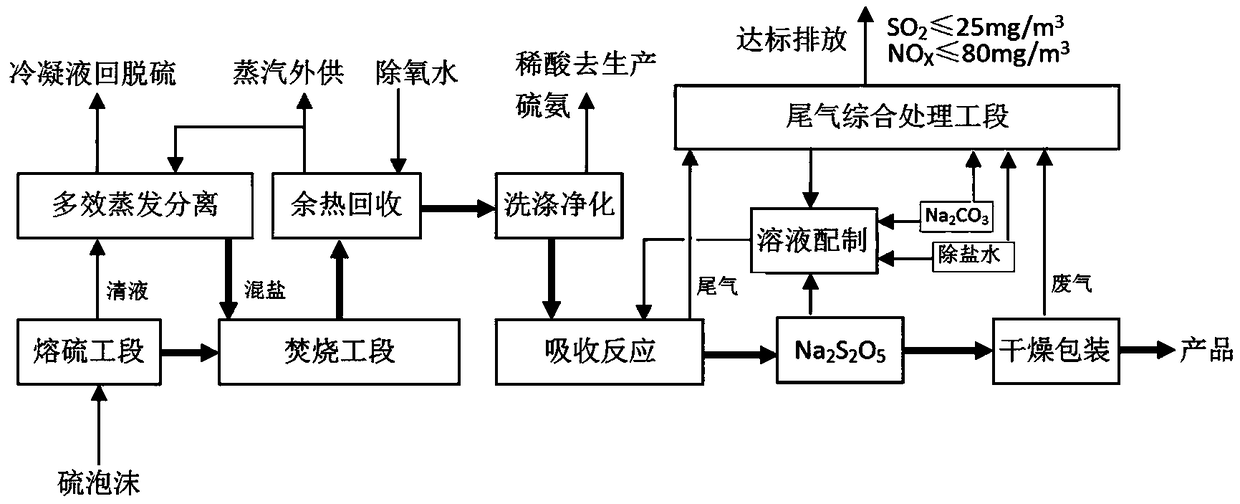

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] refer to figure 1 , a production process for sodium metabisulfite, comprising the following sections:

[0032] Sulfur melting, incineration, waste heat recovery, washing and purification, absorption, drying and packaging, tail gas treatment sections;

[0033] Described molten sulfur workshop section comprises the steps:

[0034] Firstly, the sulfur foam is separated to obtain sulfur paste and clear liquid, the sulfur paste is dried and then sent to the incineration section, the clear liquid is separated by multi-effect evaporation to obtain condensate and mixed salt, and then the condensate is returned for desulfurization, and the mixed The salt is sent to the incineration section after being dried;

[0035] Described incineration workshop section comprises the steps:

[0036] The dried sulfur paste and mixed salt are mixed with the air delivered b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com