A kind of production method of electronic grade high heat-resistant aluminum hydroxide

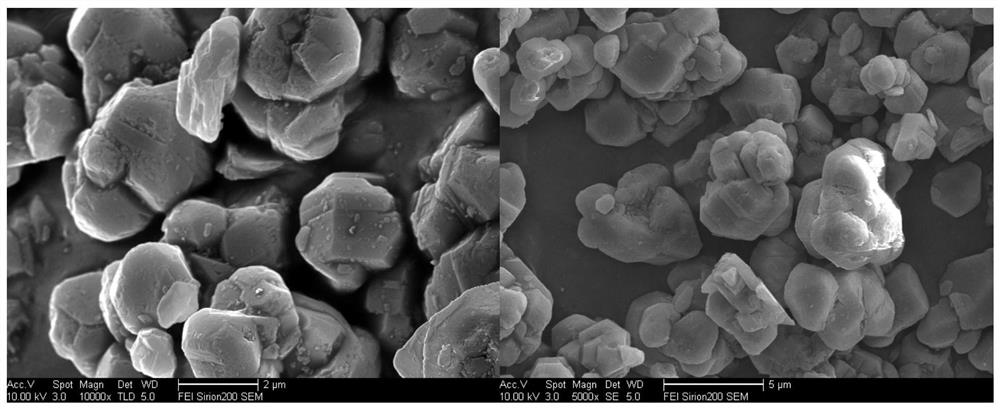

A technology of aluminum hydroxide and a production method, applied in the production of aluminum hydroxide and the production field of electronic grade high heat-resistant aluminum hydroxide, can solve problems such as high cost and complicated process, and achieve clear grain boundaries and good crystal development. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

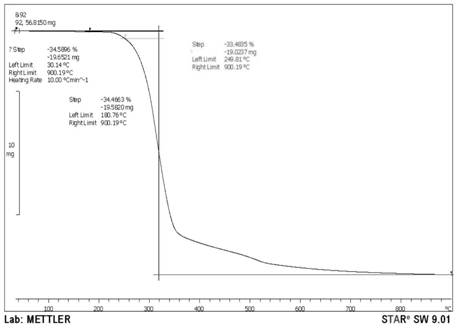

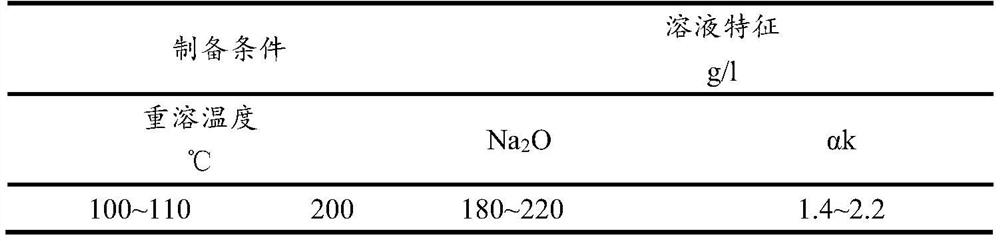

Embodiment 1

[0034] Prepare aluminum hydroxide re-dissolved solution. After dissolution, the solution is diluted with water until the concentration of sodium oxide is 150g / l, the temperature is raised to 95°C, and activated carbon is added for impurity removal. The amount of impurity remover is 1g / l, and the impurity removal time is controlled at 40 minutes. After filtering, add water to dilute, the concentration of alumina reaches 70g / l, and obtain the decomposition stock solution, take 1000ml of decomposition stock solution and add 12ml of seeds, control the initial decomposition temperature of 75°C, the final decomposition temperature of 60°C, the decomposition time of 20 hours, after washing and drying Aluminum hydroxide fine powder is obtained. The preparation conditions and characteristics of the redissolved solution used in Example 1, the characteristics of the raw materials and the indicators of the obtained samples are shown in Table 1, Table 2 and Table 3 respectively.

[0035] ...

Embodiment 2

[0042] Prepare aluminum hydroxide re-dissolved solution. After dissolution, the solution is diluted with water until the concentration of sodium oxide is 180g / l, the temperature is raised to 90°C, and silica gel is added for impurity removal. The amount of impurity remover added is 5g / l, and the impurity removal time is controlled at 60 minutes. After filtering, add water to dilute, the concentration of alumina reaches 90g / l, and obtain the decomposition stock solution, take 1000ml of decomposition stock solution and add 12ml of seeds, control the initial decomposition temperature of 75°C, the final decomposition temperature of 60°C, the decomposition time of 20 hours, after washing and drying Aluminum hydroxide fine powder is obtained. The characteristics of the raw materials used in Example 2 and the obtained sample indexes are shown in Table 3 and Table 4 respectively.

[0043] Table 3. Raw material characteristics

[0044]

[0045] Table 4. Sample Specifications

[0...

Embodiment 3

[0048] Prepare aluminum hydroxide re-dissolved solution. After dissolution, add water to dilute the solution until the concentration of sodium oxide is 160g / l, raise the temperature to 95°C, add calcium oxide for impurity removal, the amount of impurity remover added is 4g / l, and the impurity removal time is controlled in 35 minutes. After filtering, add water to dilute, the concentration of alumina reaches 110g / l, and obtain the decomposition stock solution, take 1000ml of decomposition stock solution and add 18ml of seeds, control the initial decomposition temperature of 70°C, the final decomposition temperature of 60°C, the decomposition time of 25 hours, after washing and drying Aluminum hydroxide fine powder is obtained. The characteristics of the raw materials used in Example 3 and the obtained sample indexes are shown in Table 5 and Table 6 respectively.

[0049] Table 5. Raw Material Properties

[0050]

[0051] Table 6. Sample Specifications

[0052]

[0053] N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com