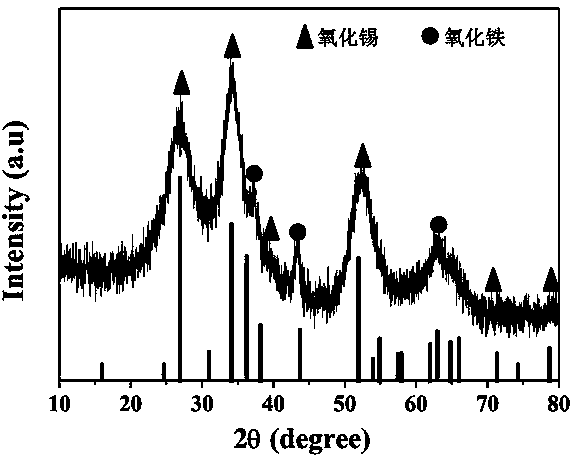

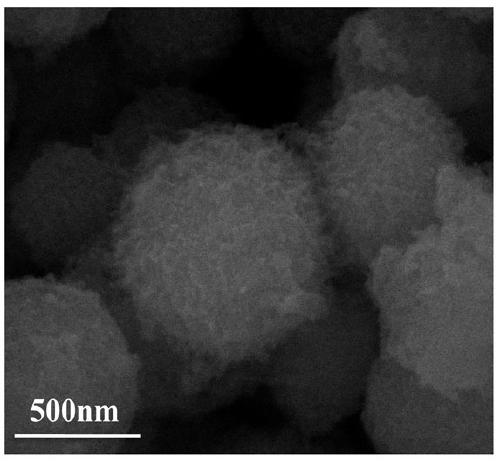

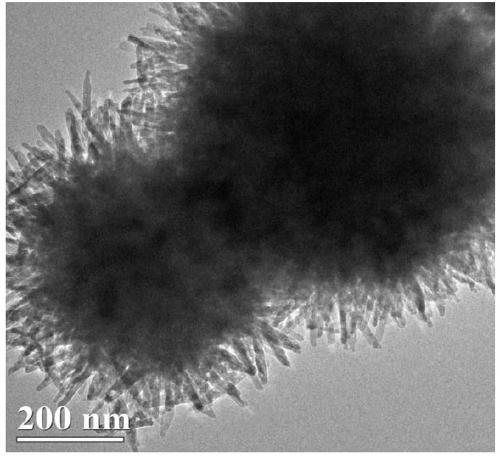

Preparation method of three-dimensional hierarchical structure tin oxide microballoon composite ferric oxide nanorod gas sensitive material

A technology of iron oxide nanometer and hierarchical structure, which is applied in the direction of iron oxide, tin oxide, iron oxide/iron hydroxide, etc., and can solve the problems of gas pollution, environmental pollution, social property loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) First measure 60 ml of methanol into a beaker, then add a certain amount of tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP), wherein the concentration of tin tetrachloride pentahydrate is 0.014 mol / L, polyvinylpyrrolidone The concentration of (PVP) is 0.003mol / L, and the molar ratio of controlling tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP) is 4.7:1;

[0019] (2) Pour the obtained solution into a 100 ml reaction kettle and keep it warm at 160 °C for 2 h; the obtained precipitates were washed three times with deionized water and twice with absolute ethanol (in this process, an ultrasonic cleaner was used to disperse , to reduce the agglomeration of particles);

[0020] (3) Add the centrifuged product obtained in step (2) into deionized water to form a uniform tin hydroxide solution, and calculate the density of the solution for the convenience of the next step;

[0021] (4) Measure 6 ml of tin hydroxide solution (14 mg / ml) in a beaker...

Embodiment 2

[0025] (1) First measure 60 ml of methanol into a beaker, then add a certain amount of tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP), wherein the concentration of tin tetrachloride pentahydrate is 0.016 mol / L, polyvinylpyrrolidone The concentration of (PVP) is 0.0035mol / L, and the molar ratio of controlling tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP) is 4.6:1;

[0026] (2) Pour the obtained solution into a 100 ml reaction kettle and incubate at 180 °C for 3 h; the obtained precipitates were washed three times with deionized water and twice with absolute ethanol (in this process, an ultrasonic cleaner was used to disperse , to reduce the agglomeration of particles);

[0027] (3) Add the centrifuged product obtained in step (2) into deionized water to form a uniform tin hydroxide solution, and calculate the density of the solution for the convenience of the next step;

[0028](4) Measure 7 ml of tin hydroxide solution (14 mg / ml) in a beaker, ad...

Embodiment 3

[0032] (1) First measure 60 ml of methanol into a beaker, then add a certain amount of tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP), wherein the concentration of tin tetrachloride pentahydrate is 0.018 mol / L, polyvinylpyrrolidone The concentration of (PVP) is 0.004mol / L, and the molar ratio of controlling tin tetrachloride pentahydrate and polyvinylpyrrolidone (PVP) is 4.5:1;

[0033] (2) Pour the obtained solution into a 100 ml reaction kettle and incubate at 200 °C for 4 h; the obtained precipitates were washed three times with deionized water and twice with absolute ethanol (in this process, an ultrasonic cleaner was used to disperse , to reduce the agglomeration of particles);

[0034] (3) Add the centrifuged product obtained in step (2) into deionized water to form a uniform tin hydroxide solution, and calculate the density of the solution for the convenience of the next step;

[0035] (4) Measure 8 ml of tin hydroxide solution (14 mg / ml) in a beaker, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com