A kind of high and low temperature resistant type trimesic acid synthetic ester plasticizer and preparation method thereof

A technology of trimesic acid and plasticizer, applied in the field of plastic additives, can solve the problem that plasticizers cannot have both high temperature resistance and low temperature resistance, and achieve low extraction resistance, improve high temperature resistance, and improve low temperature resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

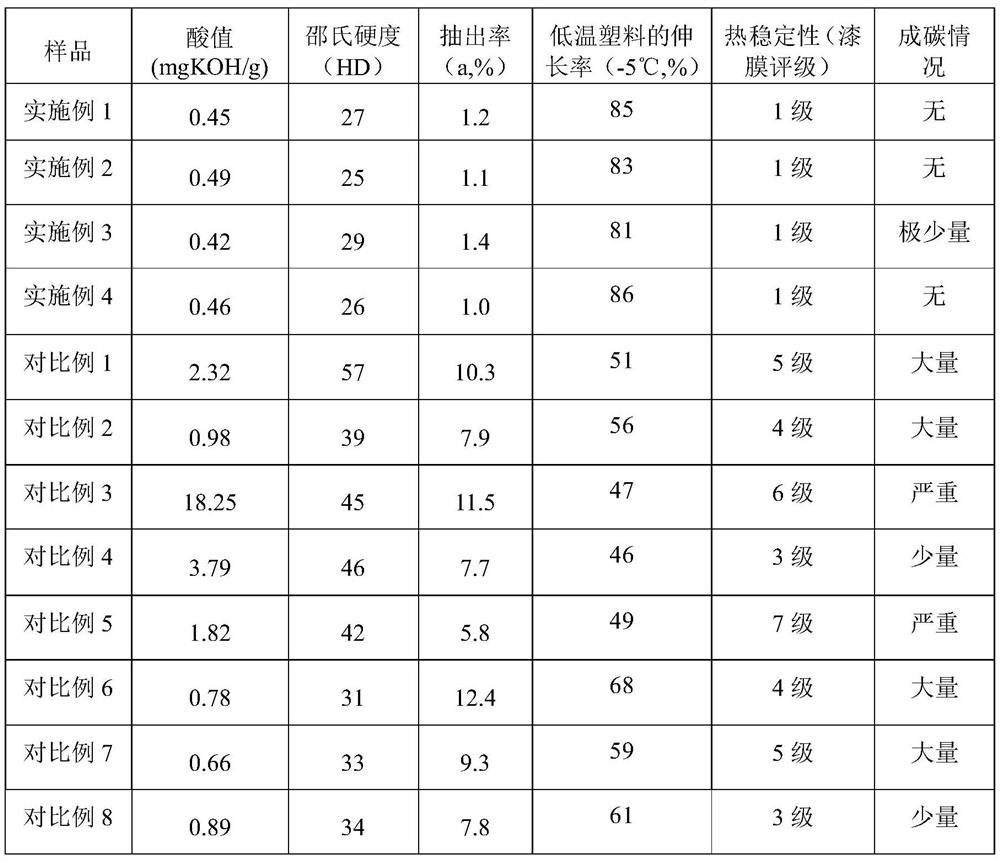

Examples

Embodiment 1

[0034] The high- and low-temperature-resistant trimesic acid synthetic ester plasticizer described in this embodiment includes the following raw material components in molar percentages based on the total amount of raw materials used to prepare the randomized plasticizer:

[0035] Trimellitic acid 25mol;

[0036] Pinacol 10mol;

[0037] Isooctyl alcohol 30mol;

[0038] 2-Ethyl hydroxyacetate 10mol;

[0039] 2-perfluorooctyl ethanol 15mol;

[0040] Xylene 10%mol;

[0041] Zinc fluoride borate 0.3mol.

[0042] The preparation method of the high and low temperature resistant type trimesic acid synthetic ester plasticizer described in this embodiment comprises the following steps:

[0043] (1) The trimesic acid, pinacol, xylene, and catalysts of selected molar amounts are added to the reactor, fully mixed and then heated to 130-150°C for water separation and esterification;

[0044] (2) Stop heating when the acid value drops below 450mgKOH / g, and add isooctyl alcohol, 2-hydr...

Embodiment 2

[0049] The high- and low-temperature-resistant trimesic acid synthetic ester plasticizer described in this embodiment includes the following raw material components in molar percentages based on the total amount of raw materials used to prepare the randomized plasticizer:

[0050] Trimellitic acid 20mol;

[0051] Pinacol 15mol;

[0052] Isooctyl alcohol 20mol;

[0053] 2-Ethyl hydroxyacetate 18mol;

[0054] 2-perfluorooctyl ethanol 12mol;

[0055] Xylene 15%mol;

[0056] Zinc fluoride borate 0.2mol.

[0057] The preparation method of the high and low temperature resistant trimesic acid synthetic ester plasticizer described in this embodiment comprises the following steps:

[0058] (1) The trimesic acid, pinacol, xylene, and catalysts of selected molar amounts are added to the reactor, fully mixed and then heated to 130-150°C for water separation and esterification;

[0059] (2) Stop heating when the acid value drops below 450mgKOH / g, and add selected molar amounts of iso...

Embodiment 3

[0064] The high- and low-temperature-resistant trimesic acid synthetic ester plasticizer described in this embodiment includes the following raw material components in molar percentages based on the total amount of raw materials used to prepare the randomized plasticizer:

[0065] Trimellitic acid 35mol;

[0066] Pinacol 6mol;

[0067] Isooctyl alcohol 26mol;

[0068] 2-Ethyl hydroxyacetate 8mol;

[0069] 2-perfluorooctyl ethanol 20mol;

[0070] Xylene 5%mol;

[0071] Zinc borofluorate 0.5mol.

[0072] The preparation method of the high and low temperature resistant trimesic acid synthetic ester plasticizer described in this embodiment comprises the following steps:

[0073] (1) The trimesic acid, pinacol, xylene, and catalysts of selected molar amounts are added to the reactor, fully mixed and then heated to 130-150°C for water separation and esterification;

[0074] (2) Stop heating when the acid value drops below 450mgKOH / g, and add selected molar amounts of isooctyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com