Preparation method of biochar/polymer composite film applied to solar water evaporation

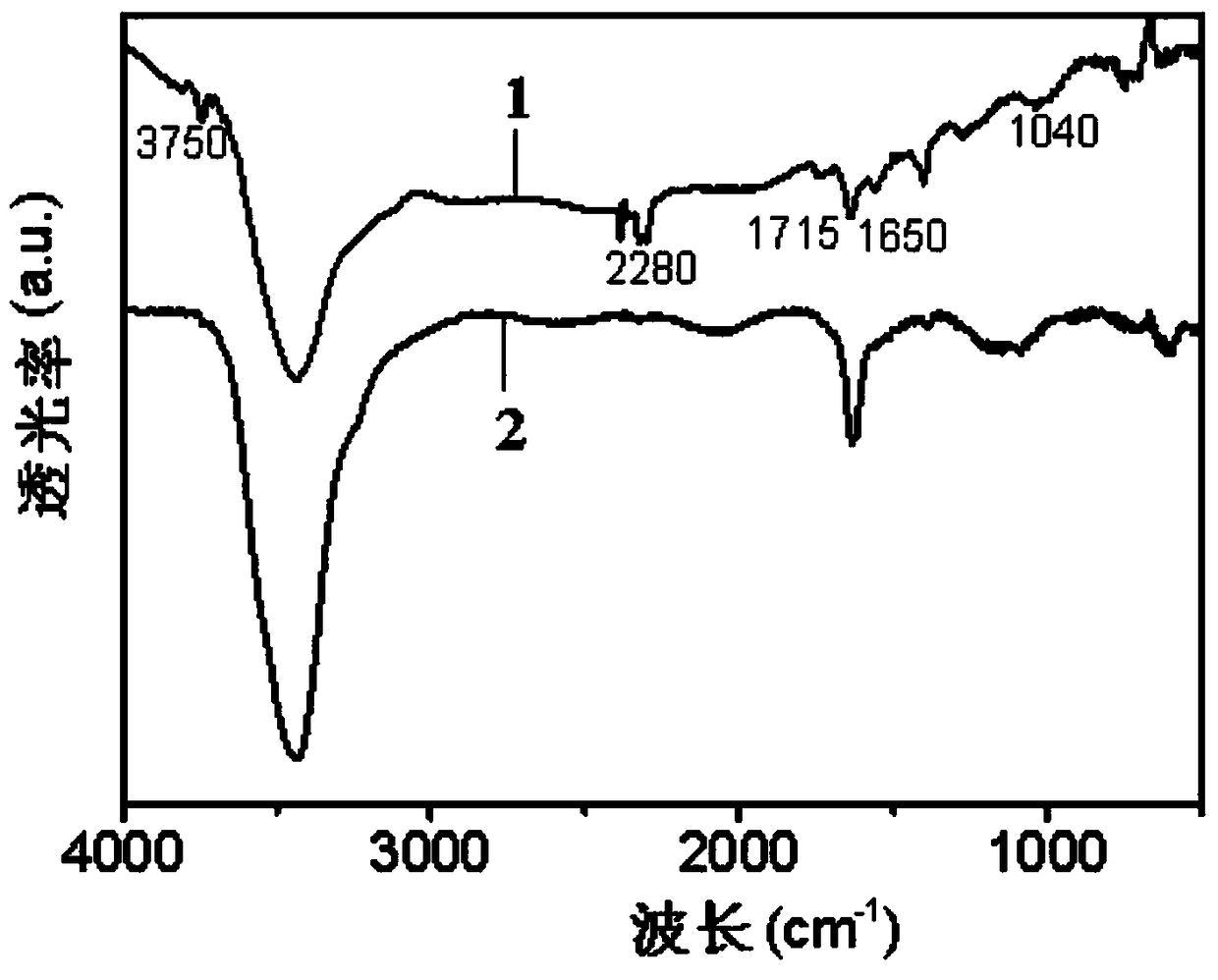

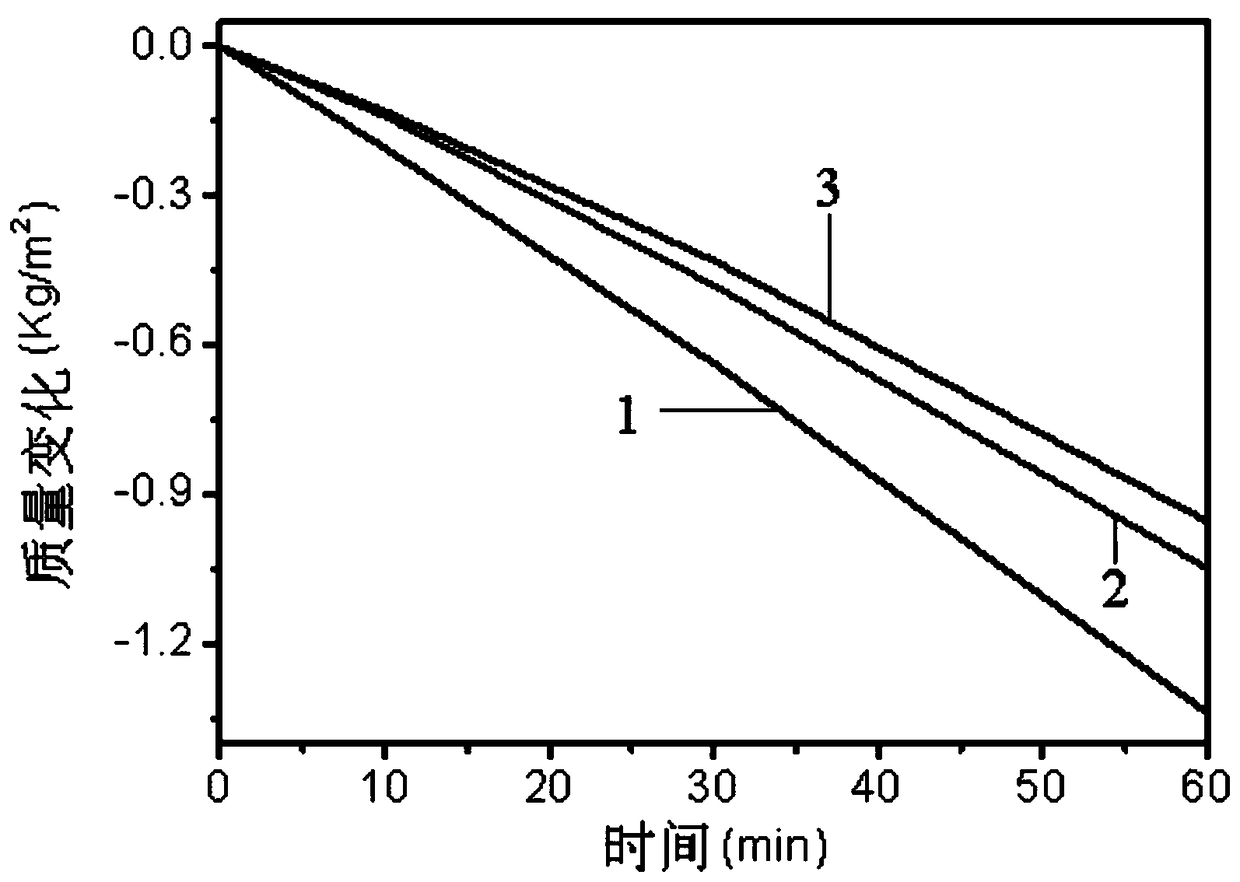

A biochar and polymer technology, which is applied in the field of composite film preparation, can solve the problem that the photothermal conversion efficiency and cost-effectiveness of photothermal evaporation elements cannot be balanced, and achieve the effects of excellent photothermal evaporation efficiency and excellent photothermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: This embodiment is a method for preparing a biochar / polymer composite film applied to solar water evaporation, specifically according to the following steps:

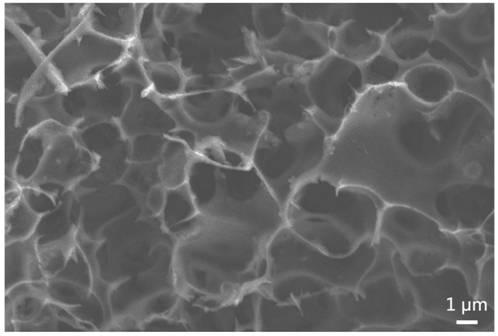

[0016] 1. Preparation of catkin biochar: Wash catkins with deionized water to remove seeds, then dry to obtain seeded catkins; put the seeded catkins into a beaker, add KOH solution with a concentration of 1moL / L to 4moL / L , ultrasonic for 30min~60min, then let stand and soak for 12h~24h, then pour it into a Buchner funnel with filter paper for solid-liquid separation, and transfer the part left in the Buchner funnel to a nickel crucible, at a temperature of 80℃~ Dry in an oven at 90°C; place the dried sample in a nitrogen muffle furnace at a heating rate of 3°C / min to 5°C / min, and keep the temperature at 550°C to 750°C for 2h to 2.5h. Cool to room temperature, take it out and put it into a beaker, then add a hydrochloric acid solution with a concentration of 1moL / L until no bubbles are generated, t...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of the concentrated sulfuric acid described in step two is 98%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass fraction of concentrated nitric acid described in step two is 68%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com