A kind of polyester resin for anti-yellowing haa system powder coating, preparation method and application

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of anti-oxidation, anti-yellowing performance, decline in anti-yellowing performance, and performance degradation, and achieve anti-yellowing performance. Excellent performance, high temperature resistance and excellent anti-yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Anti-yellowing HAA system powder coating polyester resin and preparation method thereof, comprising the following steps:

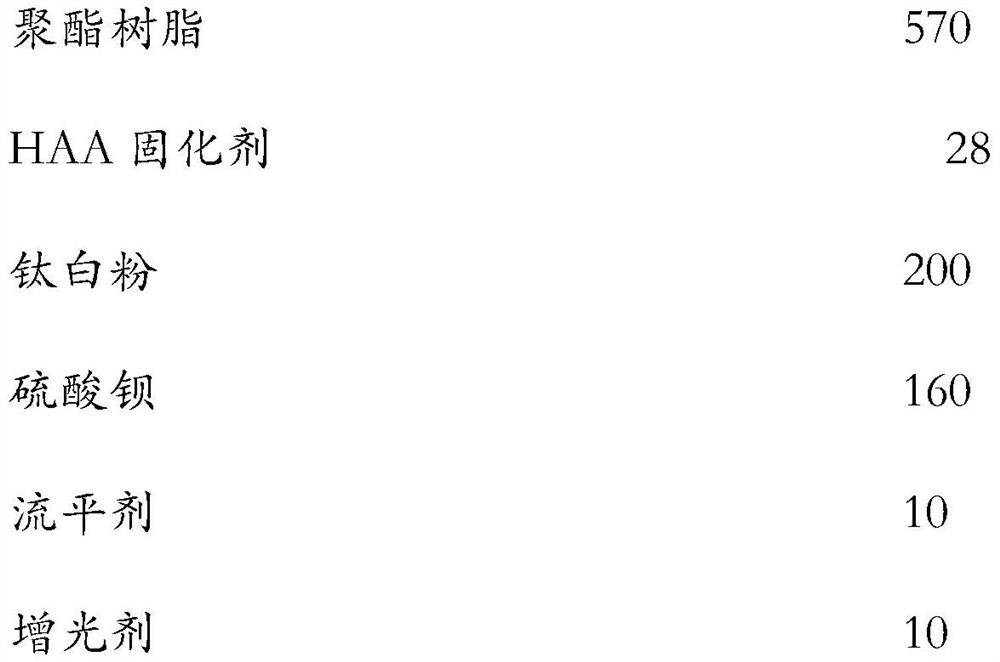

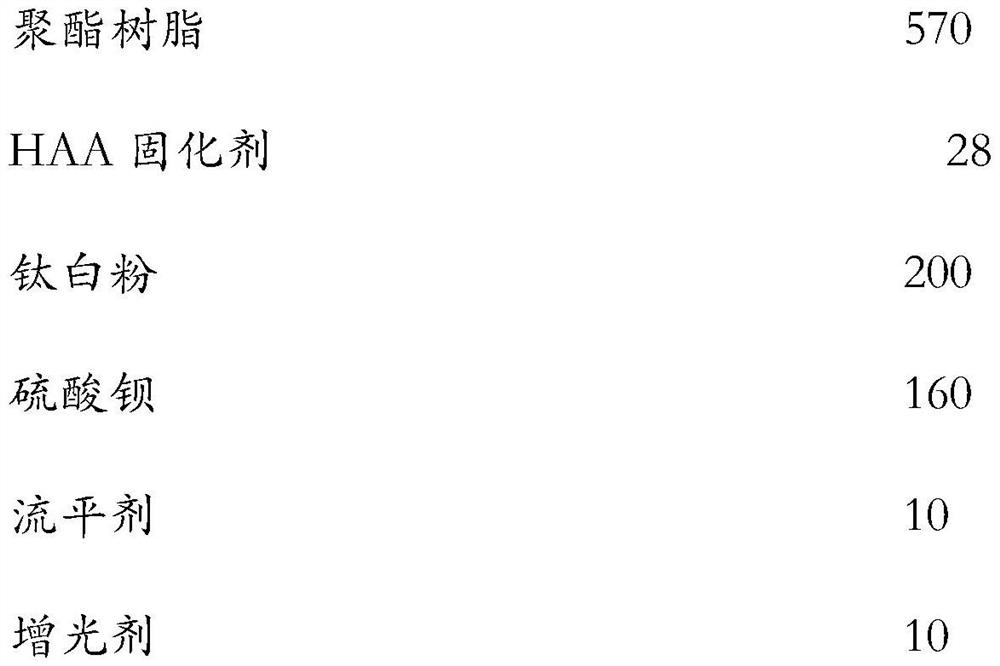

[0081] Prepare the raw materials according to the following proportions:

[0082] main ingreadient:

[0083] Pyromellitic dianhydride 12mol%; 1,6-hexanediamine 9mol%; isophthalic acid 12mol%; phloroglucinol formic acid 15mol%; ethanetricarboxylic acid monoester 12mol%; Hydroxyhexane 14mol%; Neopentyl glycol 16mol%; 2,2'-biphenyl dicarboxylic acid 10mol%;

[0084] Accessories:

[0085] Catalyst dioctyltin oxide, consumption is 0.2mol%;

[0086] Antioxidant 2,2'-thiobis(4-methyl-6-tert-butylphenol), the consumption is 0.9mol% of the total molar weight of main raw materials;

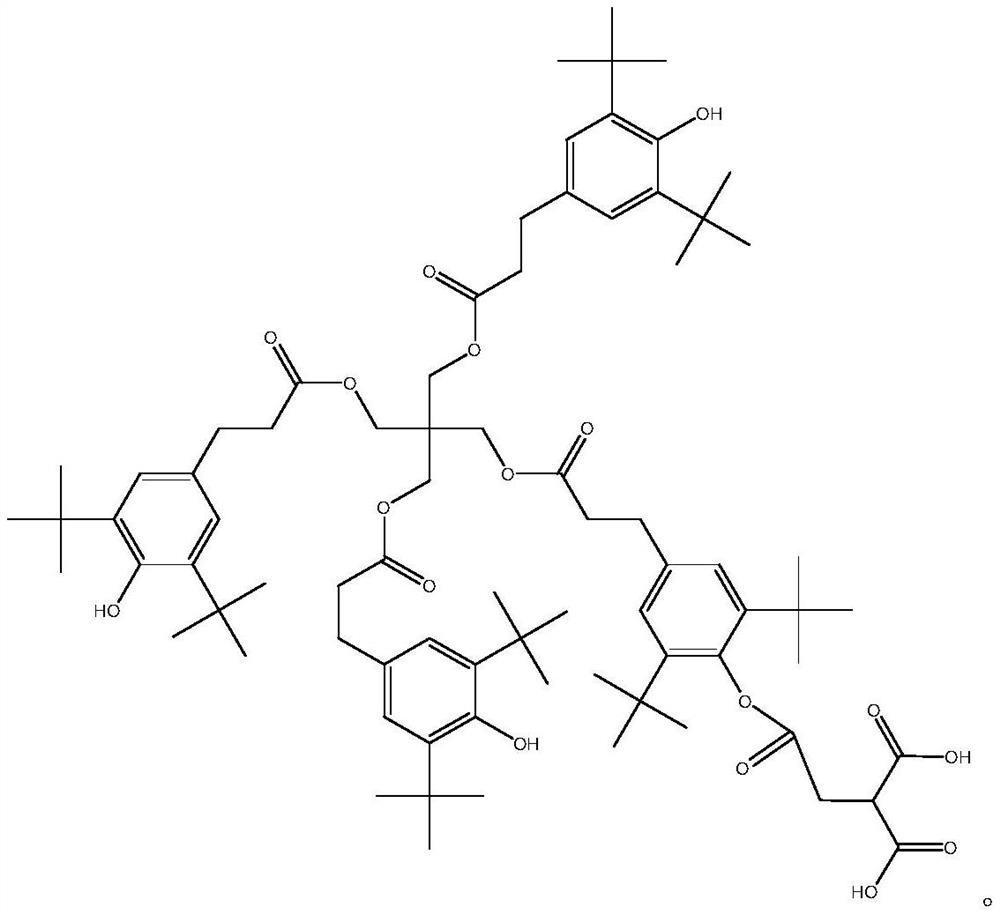

[0087] Wherein, the preparation method of ethanetricarboxylic acid monoester compound is as follows: ethanetricarboxylic acid and tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester according to molar ratio 1 Dissolve in xylene solvent in a rati...

Embodiment 2

[0127] The preparation method of the used polyester resin of anti-yellowing HAA system coating comprises the steps:

[0128] Prepare the raw materials according to the following proportions:

[0129] main ingreadient:

[0130]Pyromellitic dianhydride 9mol%; 1,6-hexanediamine 7mol%; isophthalic acid 15mol%; phloroglucinol formic acid 15mol%; ethanetricarboxylic acid monoester 14mol%; Hydroxyhexane 15mol%; Neopentyl glycol 15mol%; 2,2'-biphenyl dicarboxylic acid 10mol%;

[0131] Accessories:

[0132] Catalyst dioctyltin oxide, the dosage is 0.1mol% of the total molar weight of main raw materials;

[0133] Antioxidant 2,2'-thiobis(4-methyl-6-tert-butylphenol), the consumption is 1mol% of the total molar weight of main raw materials;

[0134] Wherein, the preparation method of ethanetricarboxylic acid monoester compound is with embodiment 1;

[0135] After preparing the ingredients, follow the steps below:

[0136] (1) Put pyromellitic dianhydride, 1,6-hexamethylenediamine a...

Embodiment 3

[0142] The preparation method of the used polyester resin of anti-yellowing HAA system coating comprises the steps:

[0143] Prepare the raw materials according to the following proportions:

[0144] main ingreadient:

[0145] Pyromellitic dianhydride 18mol%; 1,6-hexanediamine 13mol%; isophthalic acid 8mol%; phloroglucinol formic acid 12mol%; ethanetricarboxylic acid monoester 12mol%; Hydroxyhexane 14mol%; Neopentyl glycol 15mol%; 2,2'-biphenyl dicarboxylic acid 8mol%;

[0146] Accessories:

[0147] Catalyst dioctyltin oxide, the dosage is 0.3mol% of the total molar weight of main raw materials;

[0148] Antioxidant 2,2'-thiobis(4-methyl-6-tert-butylphenol), the consumption is 1.5mol% of the total molar weight of main raw materials;

[0149] Wherein, the preparation method of ethanetricarboxylic acid monoester compound is with embodiment 1;

[0150] After preparing the ingredients, follow the steps below:

[0151] (1) Put pyromellitic dianhydride, 1,6-hexamethylenediamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com