Glycan derivative of solid lubricant for drilling liquid and preparation method thereof

A technology of solid lubricant and drilling fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., which can solve the problems of reducing drilling friction, easy wear of drill pipes and drilling tools, high drilling friction and easy sticking, etc. , to achieve the effects of reducing drilling frictional resistance, convenient storage and transportation, and good high-temperature fluid loss control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

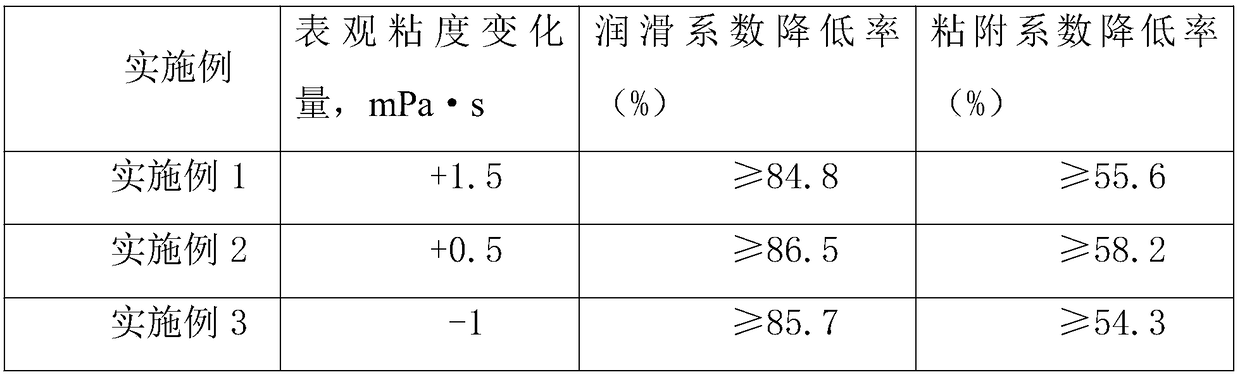

Embodiment 1

[0018] Example 1: The glycan derivatives of solid lubricants for drilling fluids of the present invention are made from raw materials with the following weight ratios: 35 parts polyethylene glycol 400, 1 part boric acid, 1 part catalyst, white oil 10 parts, 5 parts surfactant, 1 part defoamer, 25 parts mica powder, 30 parts talc powder. The white oil is a combination of three raw materials of No. 7 white oil, No. 10 white oil, and No. 15 white oil. The weight ratio of the three raw materials of No. 7 white oil, No. 10 white oil and No. 15 white oil is 1: 1.5:1.5; The surfactant is a combination of Tween T-80 surfactant and AEO-9 surfactant. The weight of Tween T-80 surfactant and AEO-9 surfactant is less than The ratio is 1:1.5; the catalyst is ferric chloride; the defoamer is polydimethylsiloxane.

[0019] The preparation method of the solid lubricant polyglycan derivative for drilling fluid includes the following process steps: ① Synthesis of borate polyethylene glycol ester: ...

Embodiment 2

[0020] Example 2: The glycan derivatives of solid lubricants for drilling fluids of the present invention are made from raw materials with the following weight ratios: 40 parts polyethylene glycol 400, 2 parts boric acid, 1.95 parts catalyst, white oil 15 parts, 3 parts surface active agent, 2 parts defoamer, 20 parts mica powder, 25 parts talc powder. The white oil is No. 7 white oil; the surfactant is a combination of two raw materials, Tween T-80 surfactant and AEO-9 surfactant, and Tween T-80 surfactant and AEO- 9 The weight ratio of the surfactant is 1:1.5; the catalyst is a combination of two raw materials, ferric chloride and aluminum chloride, and the weight ratio of ferric chloride to aluminum chloride is 1:2; The defoamer is polyoxypropylene oxide ethylene glycerol ether.

[0021] The preparation method of the solid lubricant polyglycan derivative for drilling fluid includes the following process steps: ① Synthesis of borate polyethylene glycol ester: adding 40 parts o...

Embodiment 3

[0022] Example 3: The glycan derivatives of solid lubricants for drilling fluids of the present invention are made from raw materials with the following weight ratios: 45 parts polyethylene glycol 400, 3 parts boric acid, 2 parts catalyst, white oil 20 parts, 2 parts surfactant, 3 parts defoamer, 15 parts mica powder, 20 parts talc powder. The white oil is a combination of No. 10 white oil and No. 15 white oil. The weight ratio of the two raw materials of No. 10 white oil and No. 15 white oil is 1:1.5; the surfactant is AEO -9 surfactant; the catalyst is aluminum chloride; the defoamer is polydimethylsiloxane.

[0023] The preparation method of the polyglycan derivative of solid lubricant for drilling fluid includes the following process steps: ① Synthesize polyethylene glycol borate: add 45 parts of polyethylene glycol 400 to the reactor according to the above weight ratio, and Add 3 parts of boric acid and 2 parts of catalyst to ethylene glycol 400, slowly heat to 110°C, turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com