Delayed coking device capable of reducing sulfur content of petroleum coke and increasing yield of liquid as well as coking method thereof

A delayed coking method and delayed coking technology, applied in the field of delayed coking devices, can solve the problems of poor quality of coking products and low yield of liquid products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

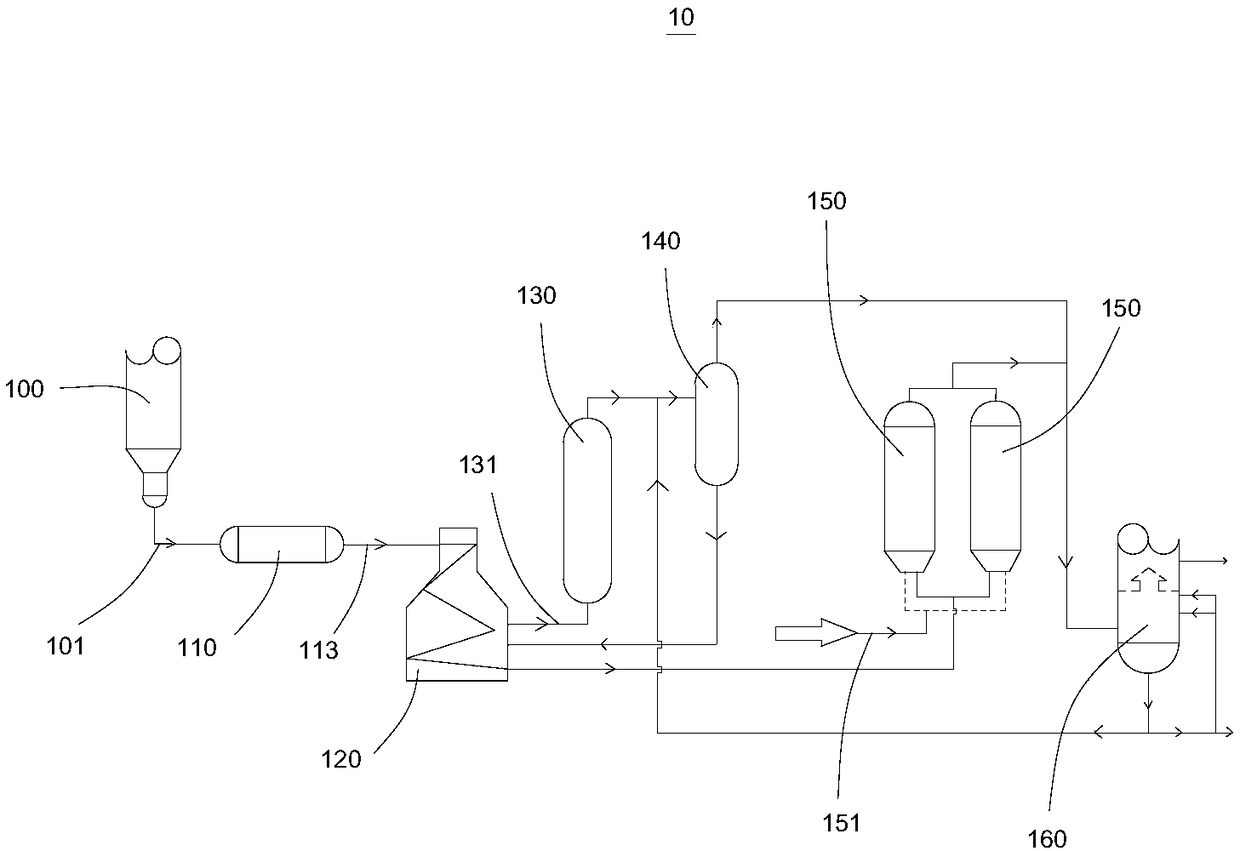

[0037] Refer again to the attached figure 1 The present embodiment provides a delayed coking device 10 for reducing the sulfur content of petroleum coke and increasing the liquid yield, which includes a coking raw material delivery pipe 101, a cavitation cracking reactor 110, a first oil and gas delivery pipe 113, and an ultrasonic reactor 130 , the second oil-gas delivery pipe 131 , the gas-liquid separator 140 , the heating furnace 120 , the coke tower 150 , the fractionation tower 160 and the high-temperature oil-gas delivery pipe 151 .

[0038] In the embodiment of the present invention, a cavitation cracking reactor 110 is introduced into the delayed coking unit 10, so that coking raw materials enter the cavitation reactor, and cavitation occurs in the reactor, accompanied by strong oxidation reactions. Cavitation is a process in which vaporization occurs when the pressure in a liquid drops below the saturated vapor pressure of the liquid at the corresponding temperature....

no. 2 example

[0047] This embodiment provides a delayed coking method for reducing the sulfur content of petroleum coke and increasing the liquid yield, which includes the following steps:

[0048] The coking raw material before the coking reaction is transported to the cavitation cracking reactor 110 for cavitation cracking reaction. In the cavitation cracking reaction, the reaction temperature is 200°C, the coking raw material is cavitated three times, the inlet pressure of the cavitation cracking reactor 110 is maintained at 5.0 MPa, and the coking raw material after cavitation cracking is transported to the heating furnace 120 The convection chamber is heated, and then the heated coking raw material is sent to the ultrasonic reactor 130 for ultrasonic strengthening.

[0049] In ultrasonic strengthening, the temperature of the ultrasonic reactor 130 is 350° C., the reaction time is 40 min, the ultrasonic frequency is 28 KHz, the power is 2000 W, and the pressure is 0.6 MPa.

[0050] The...

no. 3 example

[0056] This embodiment provides a delayed coking method for reducing the sulfur content of petroleum coke and increasing the liquid yield, which is roughly the same as the delayed coking method provided in the second embodiment, except that the parameters are different, and the differences are as follows:

[0057] In the cavitation cracking reaction, the reaction temperature is 200° C., the coking raw material undergoes cavitation treatment for 4 times, and the inlet pressure of the cavitation cracking reactor 110 is maintained at 5.0 MPa.

[0058] In ultrasonic strengthening, the temperature of the ultrasonic reactor 130 is 380° C., the reaction time is 30 minutes, the ultrasonic frequency is 28 KHz, the power is 2000 W, and the pressure is 0.6 MPa.

[0059] The high-temperature material after ultrasonic strengthening is subjected to gas-liquid separation, and the separated gas phase is transported to the fractionation tower 160 for fractionation, and the separated liquid phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com