Catalysts used for reducing petroleum coke sulfur content, and preparation method and application thereof

A technology of catalyst and sulfur content, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as the inability to reduce the sulfur content of petroleum coke and limit the use range of petroleum coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

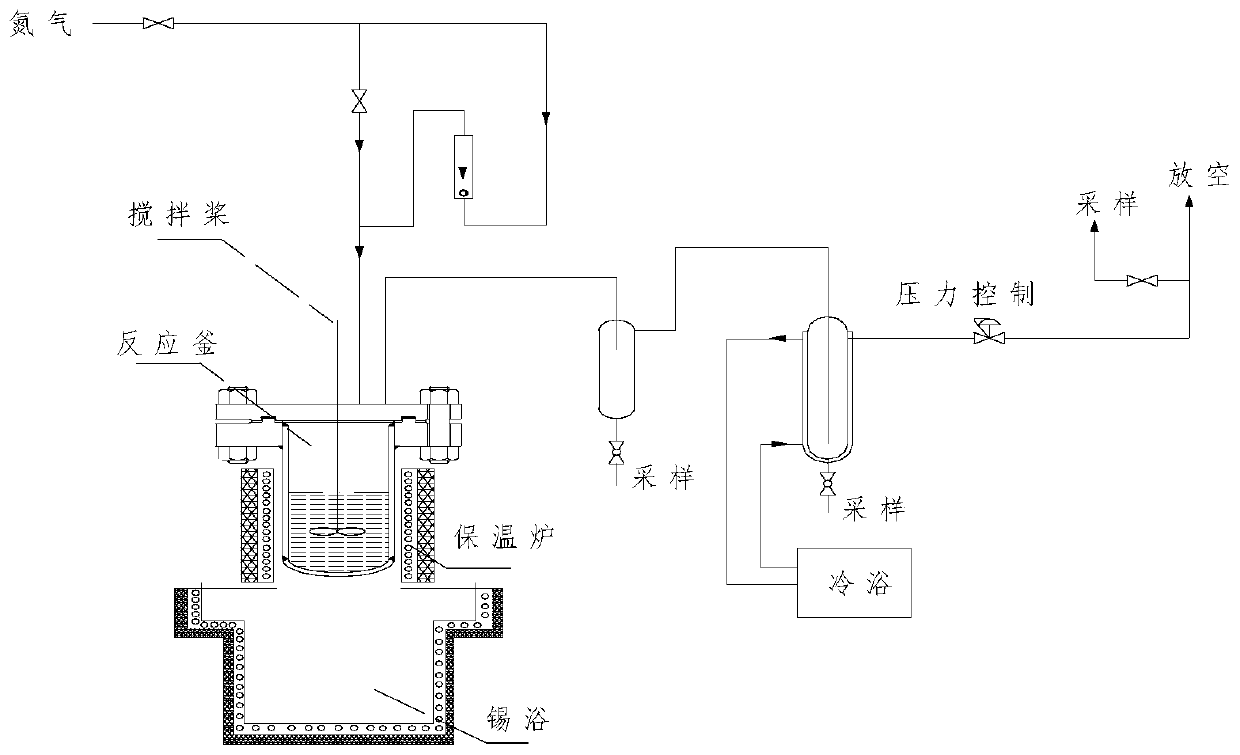

Method used

Image

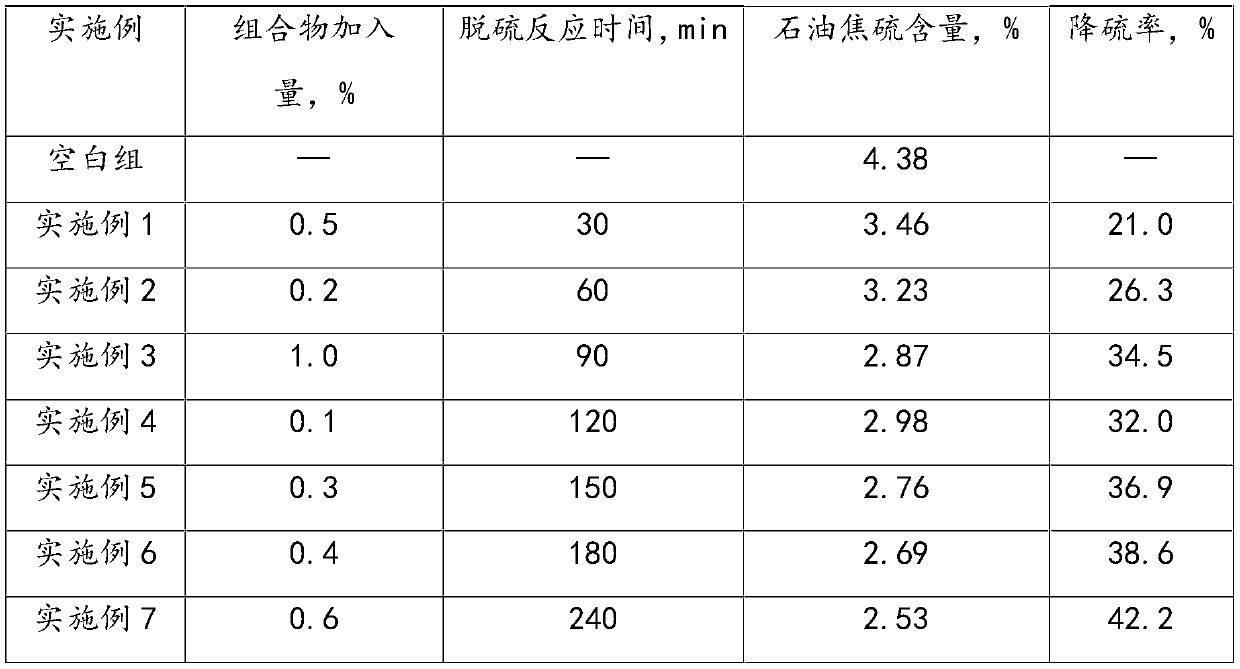

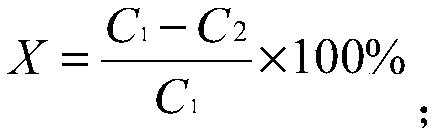

Examples

preparation example Construction

[0040] Embodiments of the present invention also provide a method for preparing a catalyst for reducing the sulfur content of petroleum coke, comprising the steps of:

[0041] S1. Vector preparation

[0042] The preparation process of the first carrier and the second carrier includes: soaking the carbonaceous particles with a particle size of ≤100 μm in an alkali solution, filtering, washing and drying, and then calcining in an inert atmosphere. The process of immersing in alkaline solution and roasting can achieve the purpose of fully expanding the pores, significantly increasing the pore diameter of the carrier, so that the final prepared catalyst product can meet the requirements of specific surface area and average pore diameter.

[0043] What needs to be added is that if the specific surface area and average pore diameter of the raw material used as the carrier meet the requirements, the modification of the carrier may not be carried out.

[0044] Specifically, the alkal...

Embodiment 1

[0063] The present embodiment provides a kind of preparation method that is used to reduce the catalyst of petroleum coke sulfur content, it comprises the following steps:

[0064] (1) The preparation method of 1# carrier: mechanically pulverize the activated carbon from the shell, sieve to obtain particles with a particle diameter not greater than 20 μm, place it in a KOH aqueous solution with a concentration of 5mol / L, soak at room temperature for 6 hours, and filter. Wash with water until neutral, dry in an oven at 80°C for 12 hours, and then place in an atmosphere furnace under N 2 Calcined at 550°C for 6 hours under atmosphere, then lowered to room temperature for use.

[0065] (2) The first catalyst: Weigh 19.5g of cobaltous nitrate hexahydrate, 19.5g of nickel nitrate hexahydrate, 15.2g of ferric nitrate nonahydrate, and 7.6g of cerium nitrate hexahydrate, put them into a beaker with a volume of 500mL, and add an appropriate amount of Distilled water, stirred for 1 hou...

Embodiment 2

[0070]The present embodiment provides a kind of preparation method that is used to reduce the catalyst of petroleum coke sulfur content, it comprises the following steps:

[0071] (1) The preparation method of 1# carrier: mechanically pulverize the activated carbon from the shell, sieve to obtain particles with a particle diameter not greater than 20 μm, place it in a KOH aqueous solution with a concentration of 5mol / L, soak at room temperature for 6 hours, and filter. Wash with water until neutral, dry in an oven at 80°C for 12 hours, then bake in an atmosphere furnace at 550°C for 6 hours under N2 atmosphere, and cool down to room temperature for use.

[0072] (2) The first catalyst: Weigh 19.5g of cobaltous nitrate hexahydrate, 19.5g of nickel nitrate hexahydrate, 15.2g of ferric nitrate nonahydrate, and 7.6g of cerium nitrate hexahydrate, put them into a beaker with a volume of 500mL, and add an appropriate amount of Distilled water, stirred for 1 hour to completely dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com