Delayed coking method and device

A delayed coking method and coking technology, applied in coking carbonaceous materials, cracking, coking ovens, etc., can solve the problems of poor quality of petroleum coke products, reduce the sulfur content of petroleum coke, increase the yield of liquid products, etc., and achieve easy implementation, Ease of secondary reaction and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

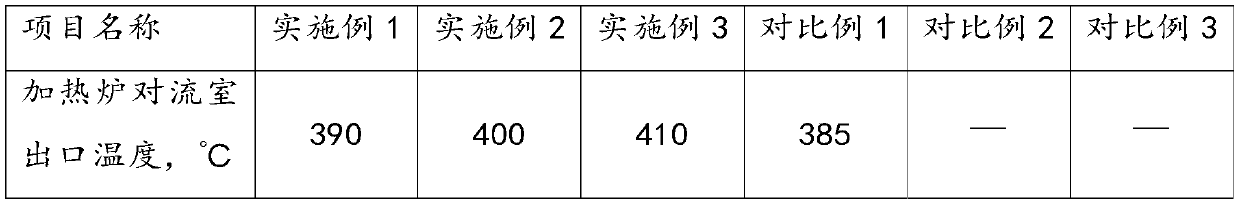

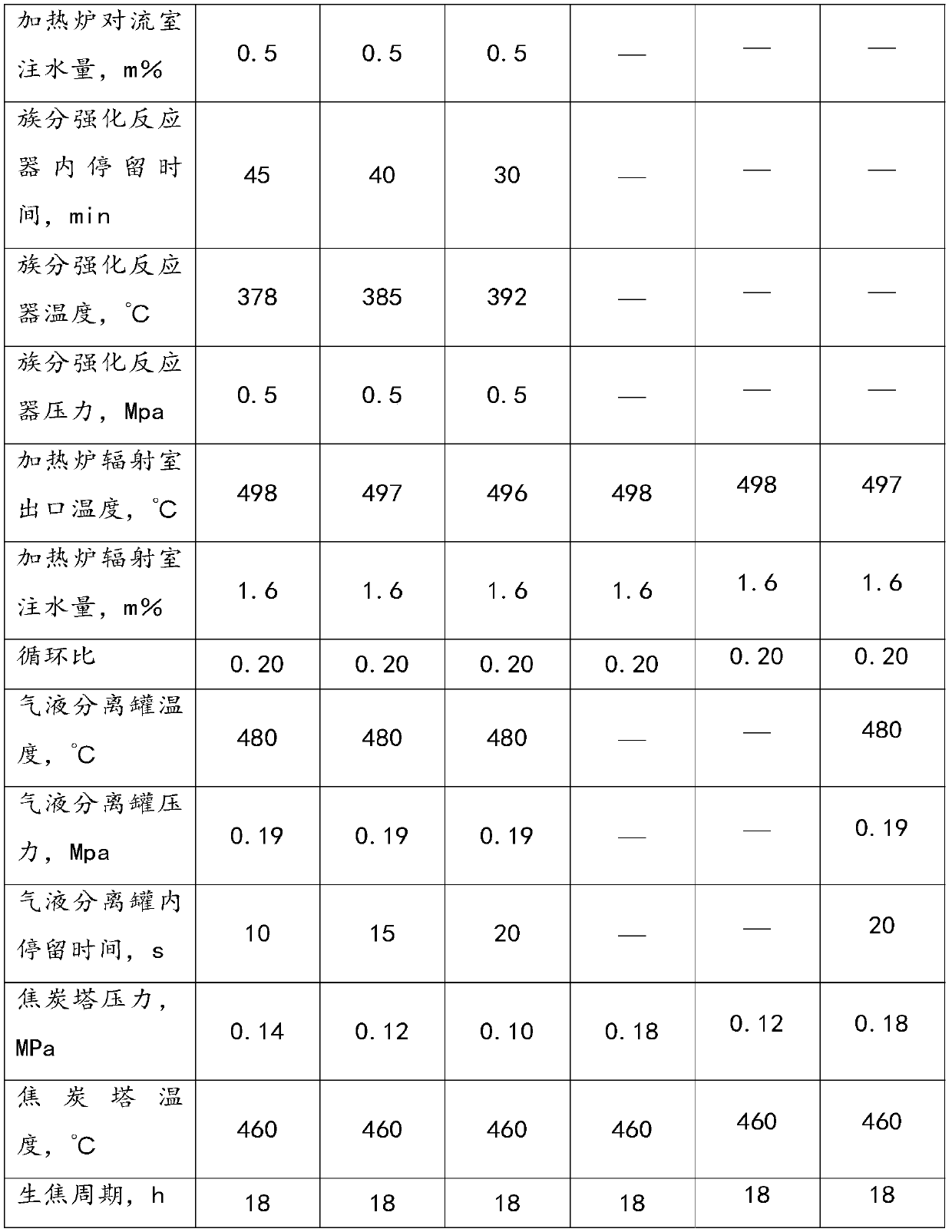

Embodiment 1

[0151] The heavy coking feedstock oil enters the ultrasonic enhanced reactor, the ultrasonic frequency is 20KHz, the power is 200W, the reaction temperature is 220°C, the reaction time is 15min, and the pressure is 0.2Mpa;

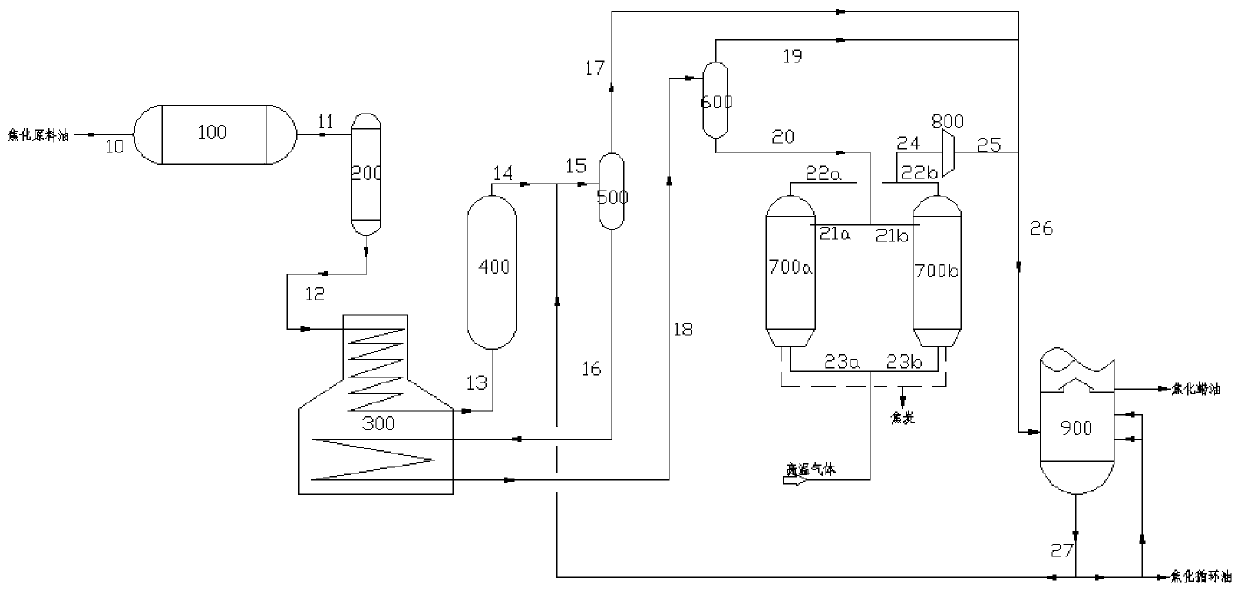

[0152] After ultrasonic treatment, the coking raw oil enters the raw oil buffer tank, and the coked raw oil exiting the raw oil buffer tank enters the convection chamber of the heating furnace, and after being heated to a certain temperature, it enters the group strengthening reactor for reaction. After the high-temperature material is mixed with the coking circulating oil from the coking fractionation tower, it enters the gas-liquid separator for gas-liquid separation. The oil gas from the top of the separator enters the fractionation tower, and the high-temperature heavy oil from the bottom of the separator enters the radiation chamber of the heating furnace for heating ;The high-temperature oil and gas leaving the heating furnace enters the gas-liquid se...

Embodiment 2

[0154] The heavy coking raw oil enters the microwave intensified reactor, the frequency of microwave radiation is 1000MHz, the reaction temperature is 200°C, the reaction time is 10min, and the pressure is 0.1MPa;

[0155] After microwave treatment, the coked feedstock oil enters the feedstock oil buffer tank; the rest is the same as in Example 1.

Embodiment 3

[0157] Pump the heavy coking raw oil at 120°C into the inlet of the throttle orifice cavitation device, and the inlet pressure of the cavitation device is 8MPa;

[0158] After cavitation, the coking feedstock oil enters the feedstock oil buffer tank; the rest is the same as in Example 1.

[0159] The temperature of the high-temperature water vapor used in each embodiment is 420° C., and the fraction with a boiling point above 470° C. at the bottom of the column is extracted from the fractionating tower as the feed of the coking cycle oil and returned to the heating furnace. Circulation ratio refers to the weight ratio of circulating oil to fresh raw oil at the bottom of fractionation tower. After the coke tower is filled with granular coke, it starts to decoke. After 120 minutes of small steam blowing and 90 minutes of big air blowing, the heavy oil in the tower is fully reacted, and then the coke tower is cooled down. When the coke tower is cooled to normal temperature, open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com