Serpentine pipe bundle waste heat recovery device

A waste heat recovery device, serpentine technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve the problems of aggravating atmospheric pollution, accelerating coal mining, consumption, etc., and achieve comprehensive product energy consumption reduction and energy saving , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

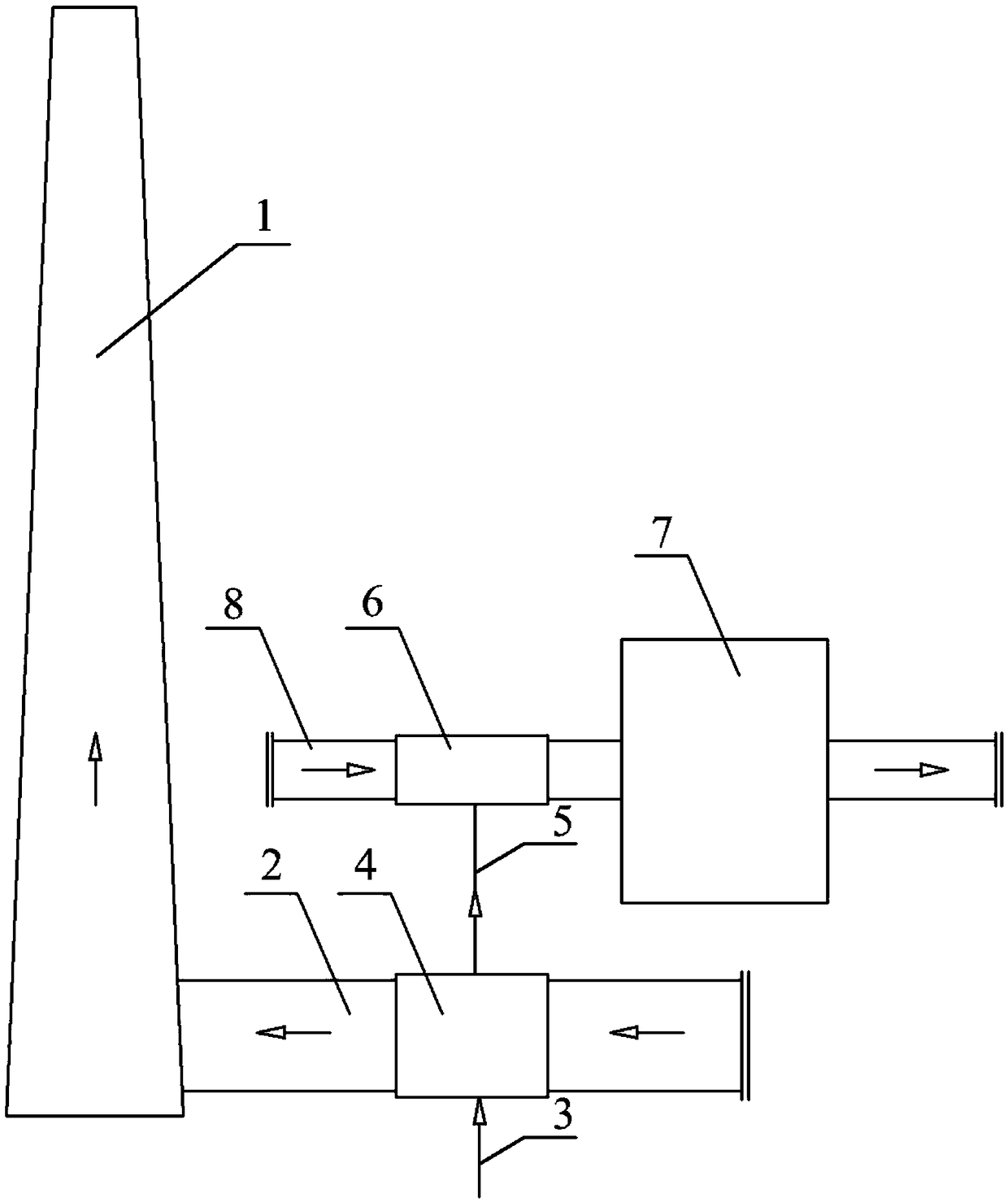

[0023] like figure 1 As shown in the figure, the arrow in the figure indicates the flue gas flow direction. A hot water heat exchanger 4 is arranged in the flue 2 of the waste heat boiler at the kiln head and kiln tail leading to the chimney 1. Cold water is diverted from the cold water pipe 3 to the hot water heat exchanger 4. The cold water Heat exchange with the flue gas in the hot water heat exchanger 4, the cold water becomes hot water after the heat exchange, and the hot water is sent to the hot air curtain 6 through the hot water pipe 5, and the heat of the outdoor air and hot water is completed in the hot air curtain 6 exchange. The heated air enters the grate cooler 7, and the high-temperature flue gas output by the grate cooler 7 is transported to the waste heat boiler to increase the flue gas temperature at the inlet of the superheater and increase the power generation.

[0024] In this embodiment, the waste heat of the flue gas discharged from the kiln head and ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com