Device for gas and/or vacuum distribution, suction unit, feeder, sheet processing machine and method for piloting a device for gas and/or vacuum distribution

A distribution device, processing machine technology, applied in the field of plate processing machine, guide the gas and/or vacuum distribution device, suction unit and feeder, can solve the problems of late suction cup advance, fast suction cup mechanical movement, early return position and other issues, to achieve the effect of increasing production speed, limiting cost and weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

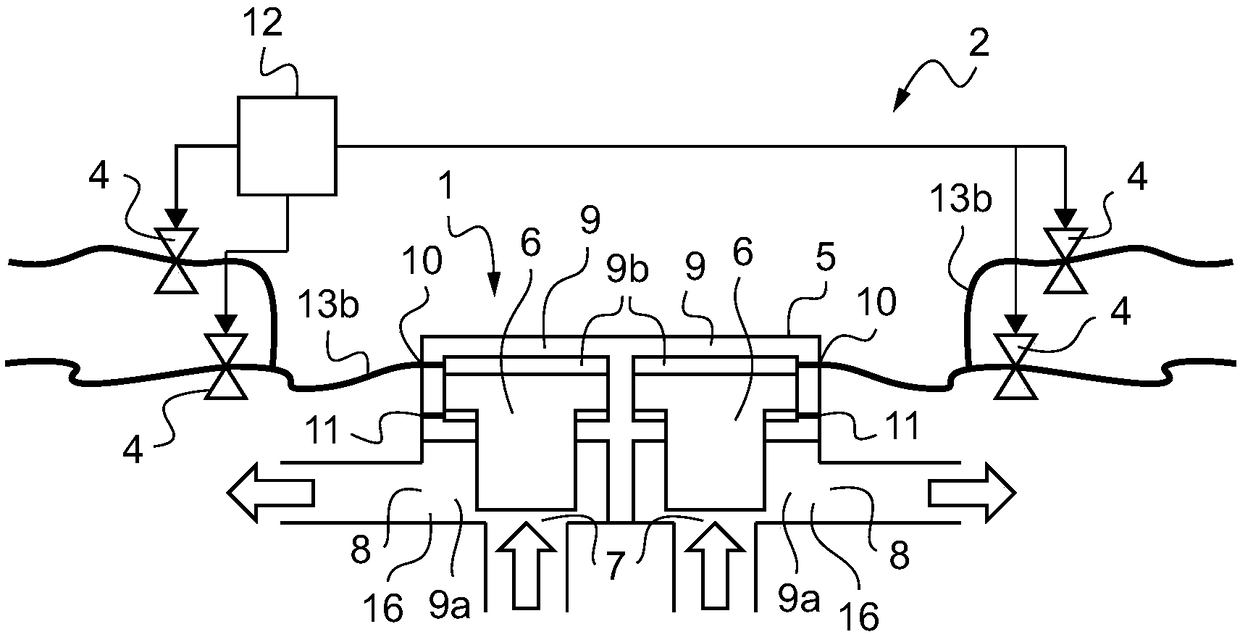

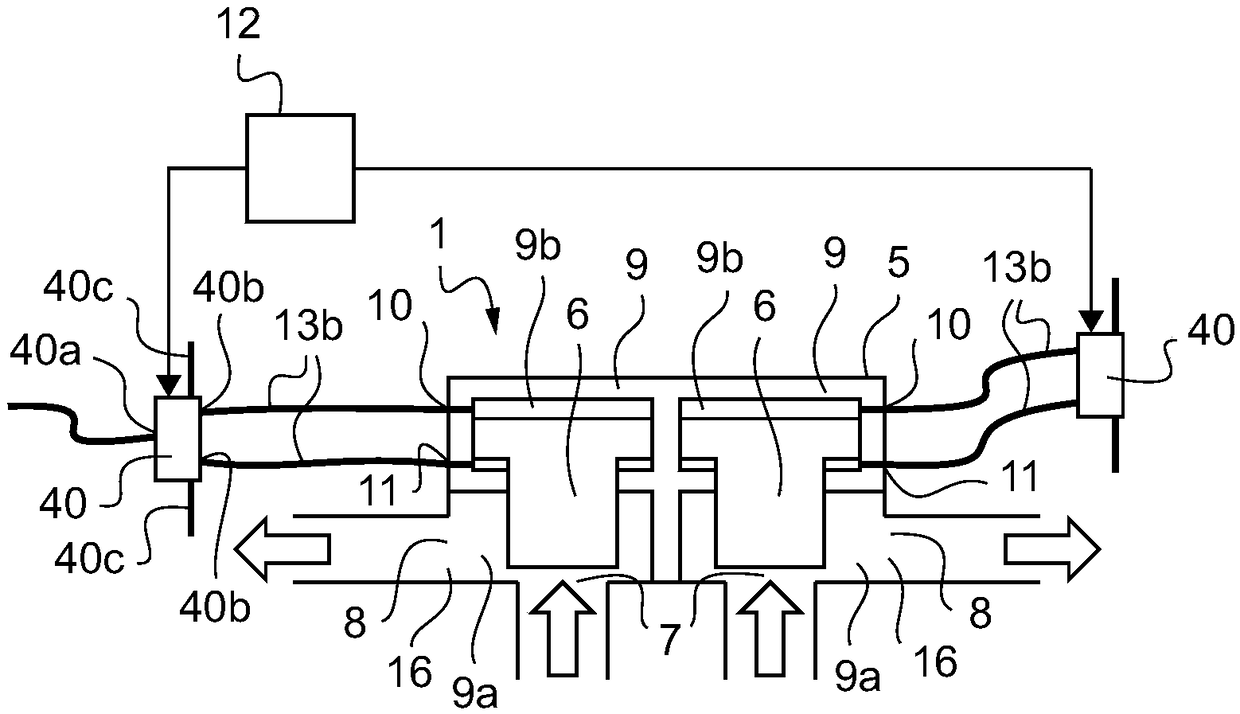

[0054] For the sake of clarity, the same elements are denoted by the same reference numerals. At the same time, only elements essential for understanding the invention are shown, which are not shown to scale in a schematic manner.

[0055] portrait, vertical and landscape orientations in Figure 4 is represented by an orthogonal space system (L, V, T).

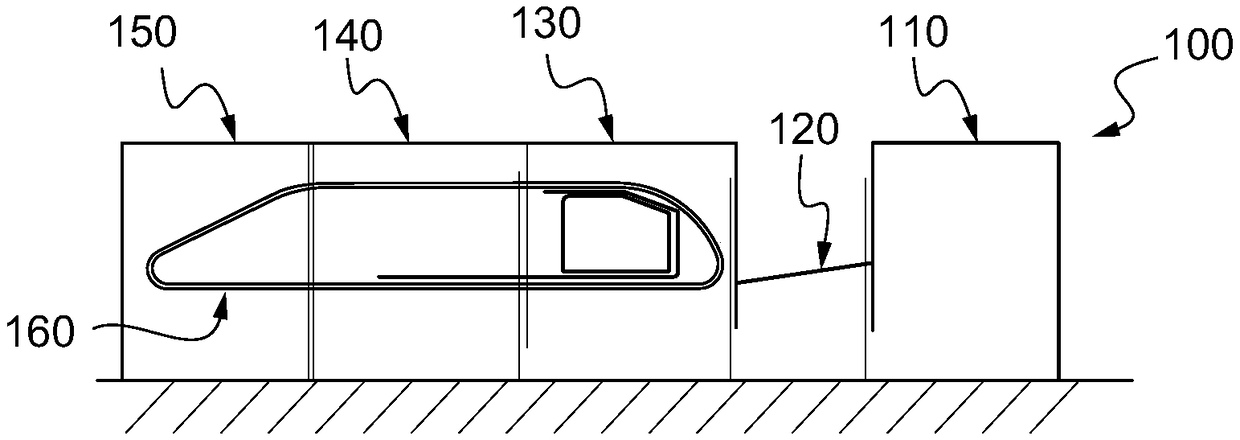

[0056] figure 1 A sheet material processing machine 100 is shown, such as a printing press, die cutter or foil stamping machine.

[0057] The board processing machine 100 allows converting board elements into packaging, for example cardboard packaging. The stamping machine 100, typically comprising a plurality of workstations 110, 120, 130, 140, 150, are arranged side by side to form a monolithic assembly capable of processing a series of flat elements. Therefore, it is necessary to provide an infeed 110 to supply the sheets individually to the machine 100, an infeed table 120 for placing the sheets in layers before precis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com