Pure instant tea and preparation method thereof

A technology of instant tea and tea leaves, which is applied in the field of food processing, can solve the problems of increased pH value, dark soup color affecting the taste of tea soup, and high production costs, and achieve the effects of preventing oxidation, inhibiting the oxidation and polymerization of tea polyphenols, and improving cold solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

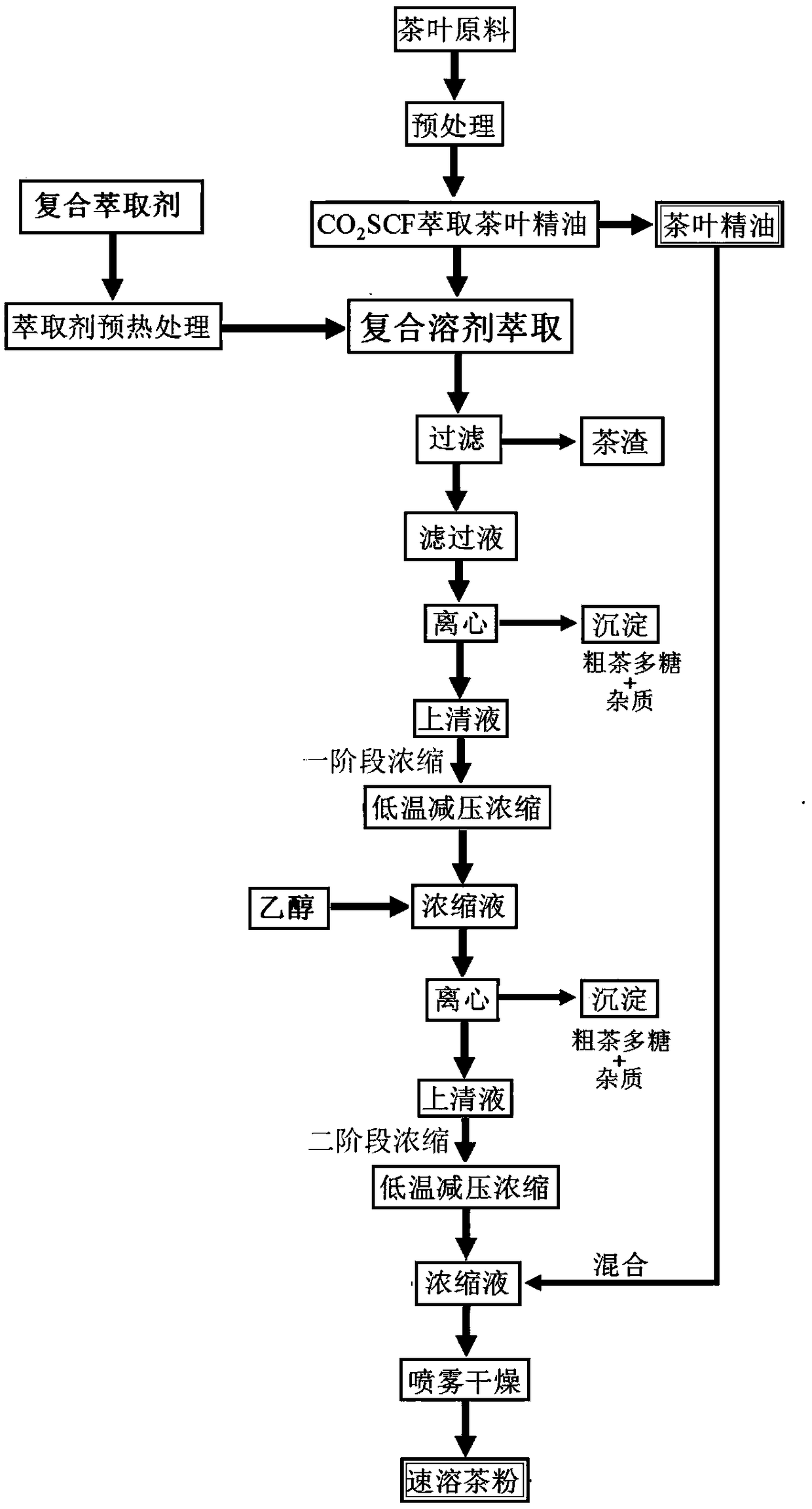

Method used

Image

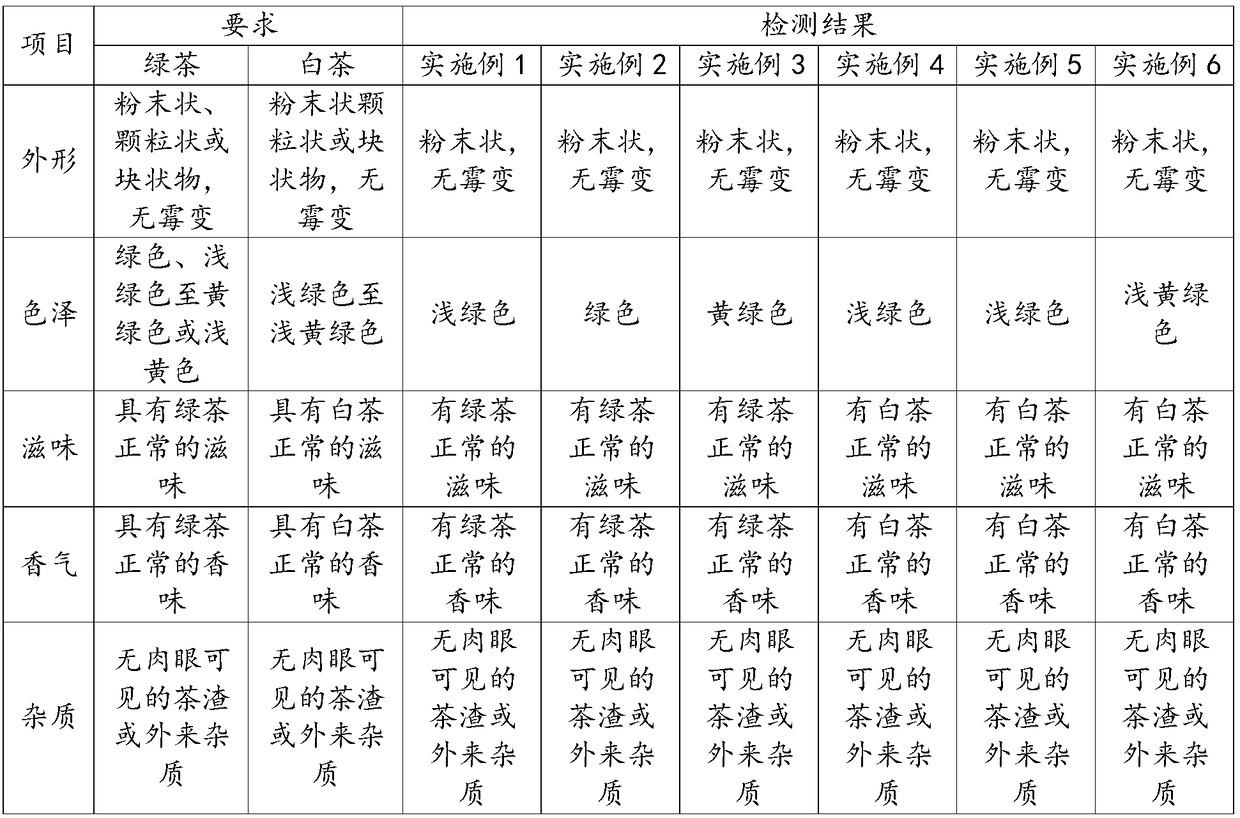

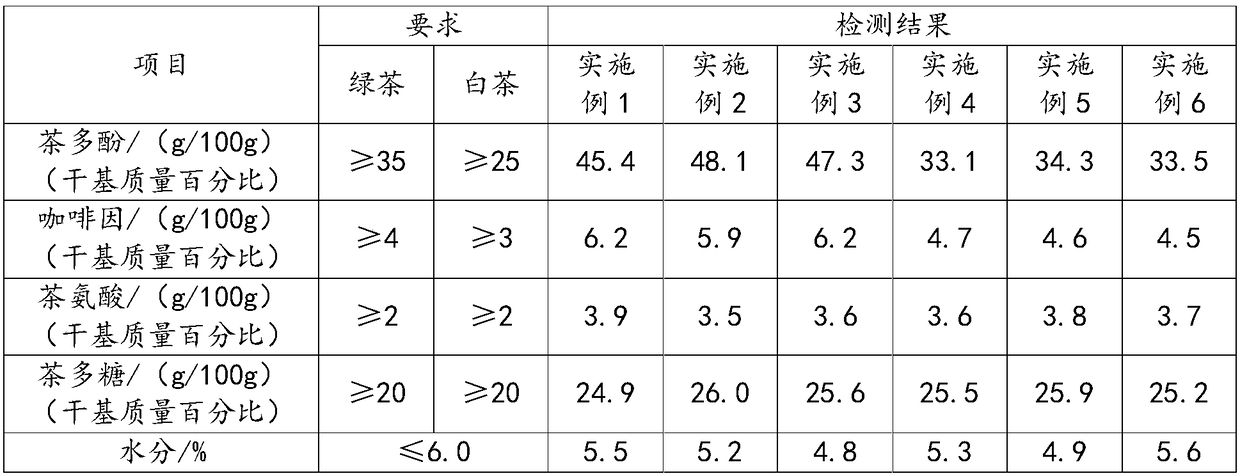

Examples

Embodiment 1

[0038] A pure green tea hot-soluble instant tea is prepared by the following method, specifically comprising the following steps:

[0039] ①Supercritical fluid extraction of tea essential oil: with CO 2 SCF entrains 5% ethanol-5% acetone as the extractant, crushes 10 kg of spring tea leaves to 10 meshes, extracts tea essential oil (flavor substances) for 2 hours at a pressure of 25MPa and a temperature of 45°C, and the flow rate of the extractant is 5L / h / kg Tea leaves; fragments, tea ash, and powdered tea produced during the processing of spring tea can also be used as raw materials;

[0040] ②Secondary cross-flow extraction: use process water: ethanol: acetone with a volume ratio of 8:1:1 as the extraction agent, and extract the tea leaves treated in step ① at a temperature of 75°C and a pH of 7.5. Add 10 times the amount of extractant to the tea leaves for the first extraction, add 5 times the amount of extractant to the tea leaves for the second extraction, and each extrac...

Embodiment 2

[0046] A pure green tea cold-soluble instant tea is prepared by the following method, specifically comprising the following steps:

[0047] ①Supercritical fluid extraction: with CO 2 SCF entrained 5% ethanol-5% acetone as extractant, 30% spring tea leaves with a ratio of 70% summer tea leaves amounted to 10kg and pulverized to 15 meshes, then extracted at a pressure of 28MPa and a temperature of 48°C for 2.5h to extract the tea essential oil ( Aroma substances), the flow rate of the extractant is 10L / h / kg tea leaves; fragments, tea ash, and end tea produced during tea processing can also be used as raw materials;

[0048] ② Three-stage countercurrent extraction: use process water: ethanol: acetone with a volume ratio of 8:1:1 as the extraction agent, and extract the tea leaves treated in step ① at a temperature of 70°C and a pH of 6.5. The ratio of agent is 1:10, and the extraction time is 25min / stage;

[0049] ③ Filtration: The material obtained in step ② is filtered throug...

Embodiment 3

[0054] A pure green tea hot-soluble instant tea is prepared by the following method, specifically comprising the following steps:

[0055] ①Supercritical fluid extraction of tea essential oil: with CO 2 SCF entrains 5% ethanol-5% acetone as the extraction agent, crushes 10 kg of spring tea leaves and autumn tea leaves according to the ratio of 1:1 to 20 meshes, and then extracts the tea essential oil under the conditions of pressure 30MPa and temperature 50°C for 3h ( Aroma substances), the flow rate of the extractant is 15L / h / kg tea leaves; fragments, tea ash, and end tea produced during tea processing can also be used as raw materials;

[0056] ②Secondary cross-flow extraction: using process water: ethanol: acetone with a volume ratio of 8:1:1 as the extraction agent, extract the tea leaves treated in step ① at a temperature of 78°C and a pH of 7.0. Add 10 times the amount of extractant to the tea leaves for the first extraction, add 5 times the amount of extractant to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com