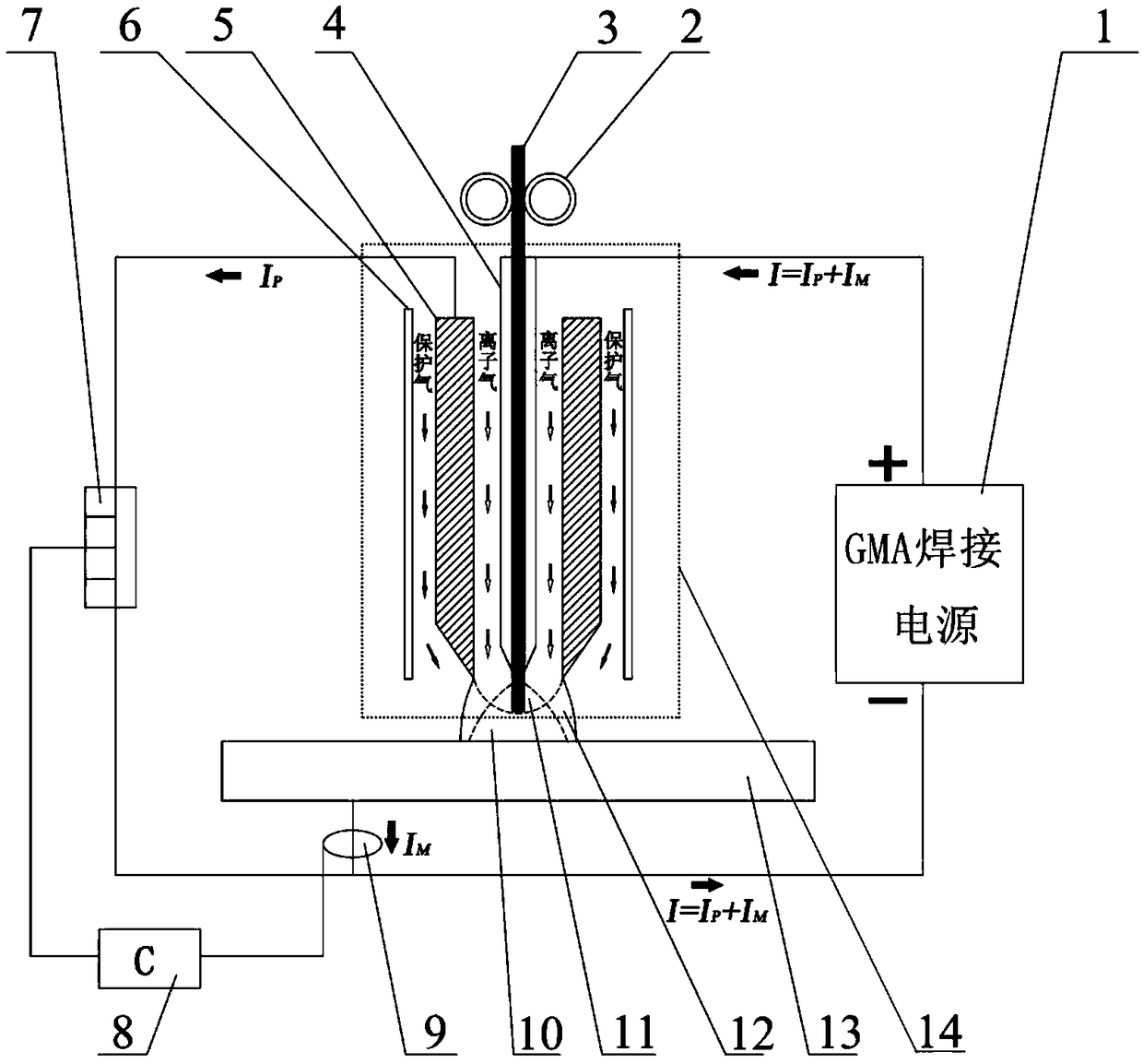

Hollow tungsten electrode shunt based consumable electrode electric-arc welding device and method

An arc welding and melting electrode welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reducing the flexibility and accessibility of welding guns, directional limitations of welding, and increasing welding defects, etc. Straightness and penetration, ensuring consistency and reliability, eliminating the effect of weld spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A metal arc welding method based on hollow tungsten shunting:

[0034] Step (1): Perform pre-welding pretreatment on the workpiece, including cleaning oil, grinding oxide layer, beveling, and selecting appropriate welding wire according to relevant requirements, and then connecting welding equipment and devices;

[0035] Step (2): According to the process requirements, select the appropriate hole diameter of the hollow tungsten electrode, adjust the distance from the hollow tungsten electrode to the contact tip to 1-3mm, avoid the short circuit between the tungsten electrode and the contact tip, make the axis of the welding torch basically perpendicular to the workpiece, and the hollow tungsten electrode The distance from the workpiece is 5-15mm, and the dry extension of the welding wire is 10-25mm

[0036] Step (3): Start the GMA welding power source, set the main circuit current I, main circuit voltage and bypass current I according to the relevant welding process P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com