Femtosecond laser preparation system and method for silicon photonic crystal waveguide device

A waveguide device and femtosecond laser technology, applied in the field of femtosecond laser preparation systems, can solve the problems of slow speed and low precision, and achieve the effects of ensuring accuracy, realizing high-precision processing and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

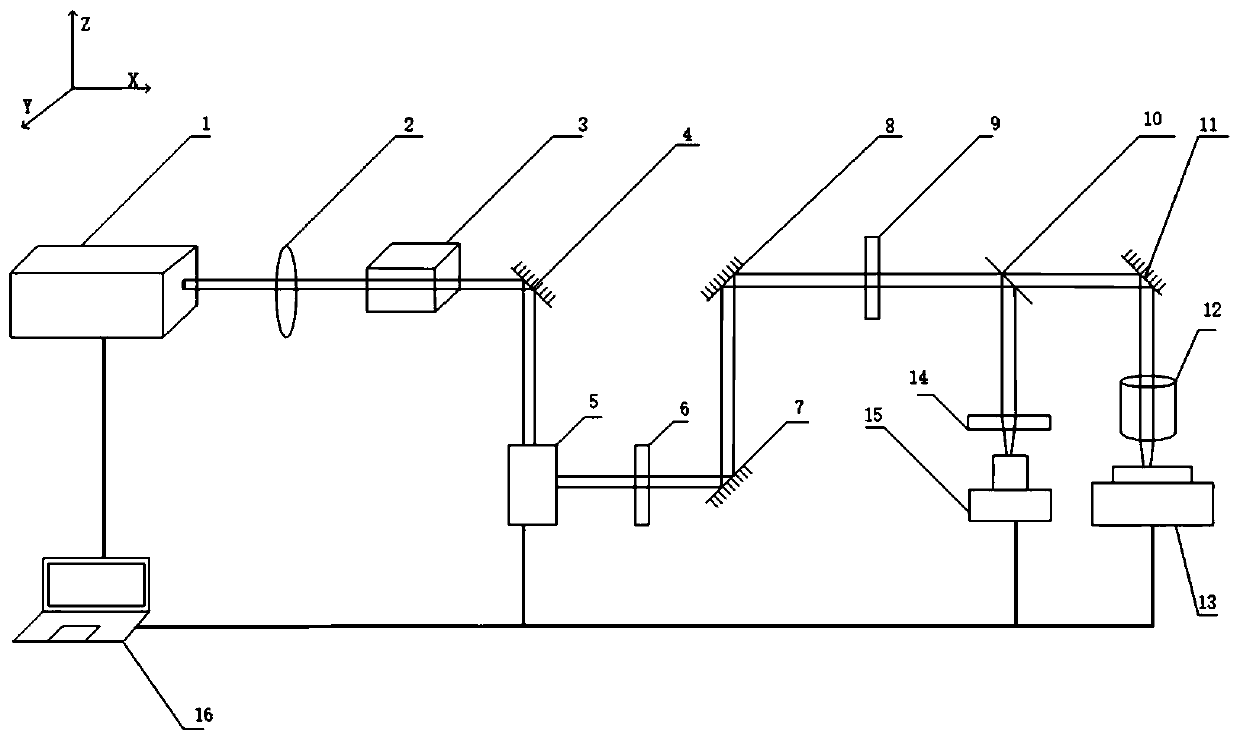

[0026] please see figure 1 A femtosecond laser preparation system for a silicon photonic crystal waveguide device provided by the present invention includes a femtosecond laser 1, a multi-stage half-wave plate 2, a polarization beam splitter prism 3, a first mirror 4, a spatial light modulator 5, a second A lens 6, a second mirror 7, a third mirror 8, a second lens 9, an electric flip mirror 10, a fourth mirror 11, a high-magnification objective lens 12, a three-dimensional processing platform 13, a third lens 14, a CCD camera 15, computer 16;

[0027] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com