Laser-dipulse MIG (metal-inert gas welding) composite heat source arc AM (additive manufacturing) method for aluminum alloy and workpieces

A composite heat source, additive manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Aluminum alloy low-power pulse laser-dual pulse MIG composite heat source additive manufacturing of thin-walled wall accumulation. The low-power pulse laser-dual pulse MIG compound heat source additive manufacturing system consists of LWS-500YAG solid-state pulse laser with a maximum output power of 500W, WB-P500L MIG / MAG welding machine and OTC FD-V20 welding robot.

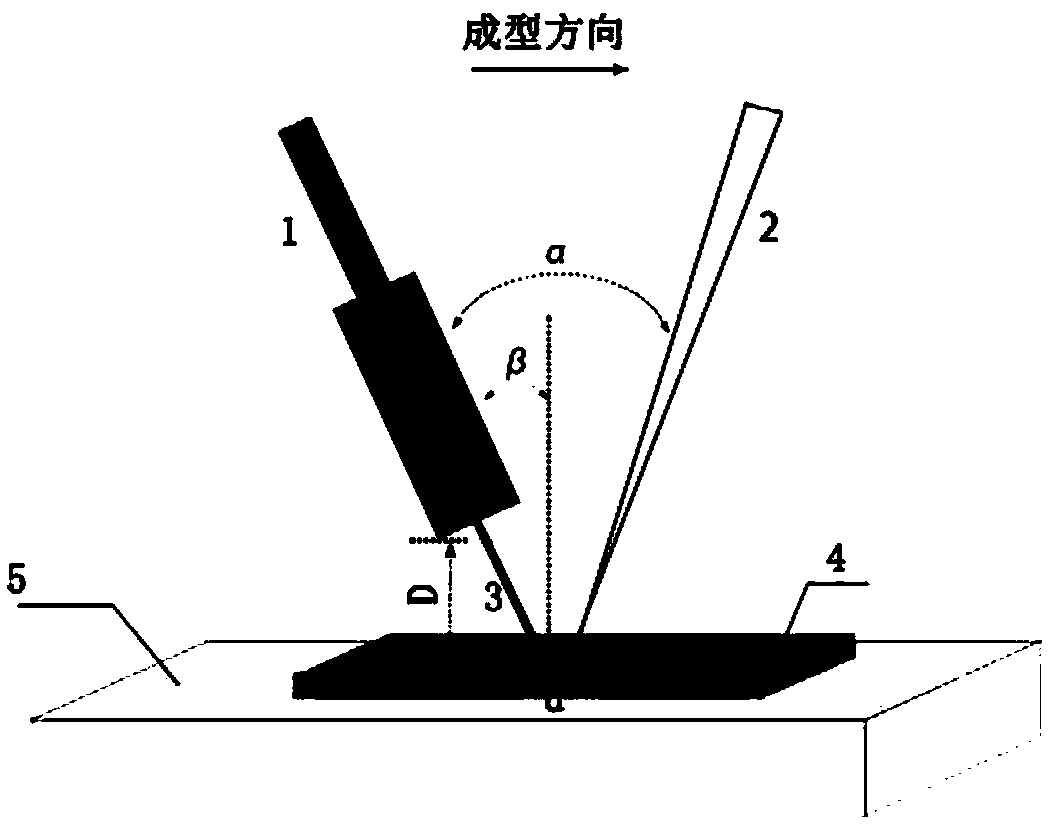

[0056] The welding wire model is ER5356, with a diameter of 1.2mm. The composite method is adopted in which the laser is in front and the arc is in the back. The shielding gas is 98% Ar gas. The test substrate is 300mm×300mm×5mm 5356 aluminum alloy plate, the distance D between the front end of the MIG welding torch and the substrate is 13mm, the angle α between the laser gun and the double-pulse MIG welding torch is 45°, and the angle β between the MIG welding torch and the vertical direction is 25°, distance d of light filaments is 2mm, MIG current is 120A, laser power is 400W, stacking speed is 600mm / m...

Embodiment 2

[0059] Aluminum alloy low-power low-power pulse laser-double pulse MIG composite heat source additive manufacturing of multi-layer and multi-layer physical accumulation. The low-power pulse laser-dual pulse MIG compound heat source additive manufacturing system consists of LWS-500YAG solid-state pulse laser with a maximum output power of 500W, WB-P500L MIG / MAG welding machine and OTC FD-V20 welding robot.

[0060] The welding wire model is ER2219, the diameter is 0.8mm, and the composite method is adopted in which the laser is in front and the arc is in the back, and the shielding gas is 98% Ar gas. The test substrate is made of 300mm×300mm×10mm 2219 aluminum alloy plate, the distance D between the front end of the MIG welding torch and the substrate is 18mm, the angle α between the laser gun and the double-pulse MIG welding torch is 50°, and the angle β between the MIG welding torch and the vertical direction is 15°, the spacing d of light filaments is 4mm, the MIG current is...

Embodiment 3

[0062] Aluminum alloy low-power low-power pulse laser-double pulse MIG composite heat source additive manufacturing single-channel multi-layer wall accumulation. Low-power pulse laser-dual pulse MIG compound heat source additive manufacturing system consists of LWS-1000YAG solid-state pulse laser with a maximum output power of 1000W, WB-P500L MIG / MAG welding machine and OTC FD-V20 welding robot.

[0063] The welding wire model is ER4043, the diameter is 1.6mm, and the composite method is adopted in which the laser is in front and the arc is in the back, and the shielding gas is 98% Ar gas. The test substrate is 300mm×300mm×5mm 4043 aluminum alloy plate, the distance D between the front end of the MIG welding torch and the substrate is 10mm, the angle α between the laser gun and the double-pulse MIG welding torch is 35°, and the angle β between the MIG welding torch and the vertical direction is 30°, the spacing d of light filaments is 1mm, the MIG current is 135A, the laser po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com