A kind of seabuckthorn leaf cellulose fiber

A technology of cellulose fibers and sea buckthorn leaves, applied in the field of cellulose fibers, can solve problems such as undiscovered, and achieve the effects of increasing overall income, promoting wound healing, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

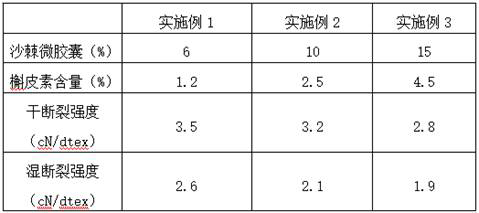

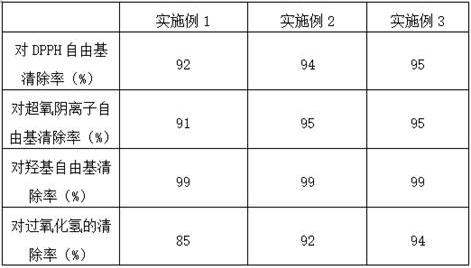

Embodiment 1

[0066] Embodiment 1 A kind of seabuckthorn leaf cellulose fiber, its preparation method comprises the following steps:

[0067] (1) Preparation of seabuckthorn extract

[0068] a. Wash the seabuckthorn leaves, place them in an oven at 40°C for drying, and dry them with a moisture content of 15%, then crush them into 100-200 mesh seabuckthorn leaf powders;

[0069] b. Put the seabuckthorn leaf powder in the solution S1 for extraction.

[0070] In the solution S1, the concentration of ethanol is 20%, the concentration of isopropyl ketone is 40g / L, mixed and stirred at a certain speed and extracted to obtain the A1 solution, and the extraction time is 20min; acetic acid is added to the A1 solution to adjust the pH to 3.5 to obtain B1 liquid;

[0071] The solid-liquid ratio of seabuckthorn leaf powder to solution S1 is 1:20;

[0072] c. Further ultrasonically extracting the B1 solution to obtain the C1 solution;

[0073] The ultrasonic extraction power is 120W, the frequency i...

Embodiment 2

[0098] Embodiment 2 A kind of seabuckthorn leaf cellulose fiber, its preparation method comprises the following steps:

[0099] (1) Preparation of seabuckthorn extract

[0100] a. Wash the seabuckthorn leaves, place them in an oven at 45°C for drying, and dry them with a moisture content of 15%, then crush them into 100-200 mesh seabuckthorn leaf powders;

[0101] b. Put the seabuckthorn leaf powder in the solution S1 for extraction.

[0102] In the solution S1, the concentration of ethanol is 25%, the concentration of isopropanone is 45g / L, and the A1 solution is obtained by mixing and stirring at a certain speed, and the extraction time is 30 minutes; the pH is adjusted to 5.5 by adding acetic acid to the A1 solution to obtain the B1 solution ;

[0103] The solid-liquid ratio of seabuckthorn leaf powder to solution S1 is 1:30;

[0104] c. Further ultrasonically extracting the B1 solution to obtain the C1 solution;

[0105] The ultrasonic extraction power is 150W, the fre...

Embodiment 3

[0130] Embodiment 3 A seabuckthorn leaf cellulose fiber, its preparation method comprises the following steps:

[0131] (1) Preparation of seabuckthorn extract

[0132] a. Wash the seabuckthorn leaves, place them in an oven at 50°C for drying, and dry them with a moisture content of 20%, then crush them into 100-200 mesh seabuckthorn leaf powders;

[0133] b. Put the seabuckthorn leaf powder in the solution S1 for extraction.

[0134] In the solution S1, the concentration of ethanol is 30%, the concentration of isopropanone is 60g / L, mixed and stirred at a certain speed and extracted to obtain A1 solution, the extraction time is 40min; acetic acid is added to the A1 solution to adjust the pH to 5.5 , to obtain liquid B1;

[0135] The solid-liquid ratio of described seabuckthorn leaf powder and lysate S1 is 1: 40;

[0136] c. Further ultrasonically extracting the B1 solution to obtain the C1 solution;

[0137] The ultrasonic extraction power is 150W, the frequency is 20kHz,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com