A rotorless jet spray fan

A spray fan and rotorless technology, which is applied in spraying devices, liquid spraying devices, etc., can solve the problems of increasing power per unit area and heat flux density, reducing work efficiency, and small physical size, and achieves fast spraying speed, simple structure, and easy replacement. Strong heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

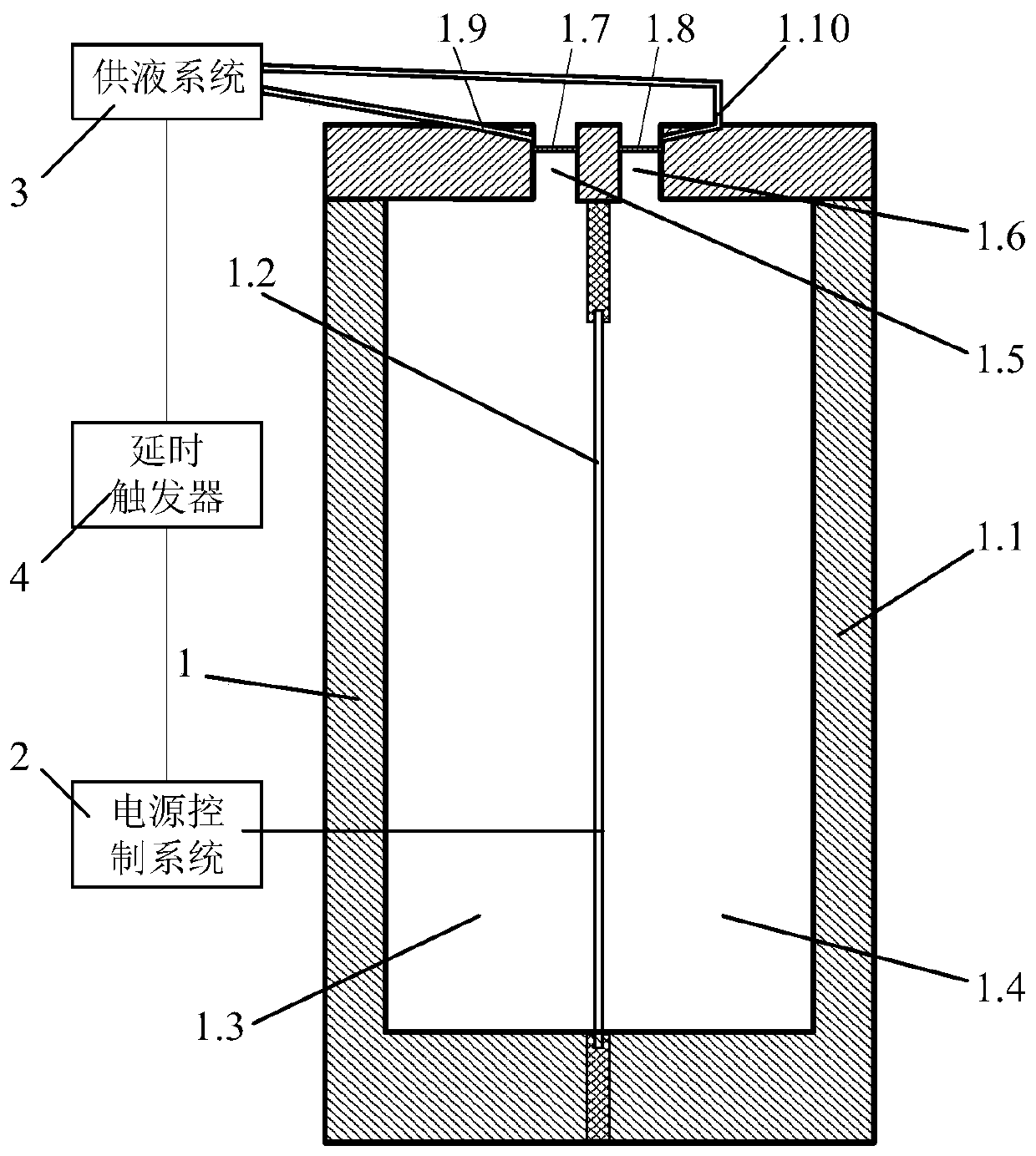

[0029] A rotorless jet spray fan includes a power supply control system 2, a jet exciter 1, a liquid supply system 3 and a delay trigger 4.

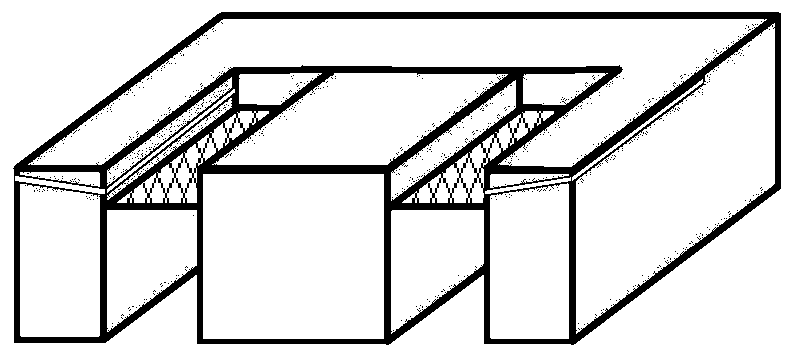

[0030] The jet actuator 1 includes a casing 1.1, and the casing 1.1 is provided with a vibrating membrane 1.2. In this embodiment, the vibrating membrane 1.2 is a piezoelectric vibrating membrane, and its vibration is driven by piezoelectricity. The vibrating membrane 1.2 divides the cavity in the housing 1.1 into two independent cavities, respectively the first cavity 1.3 and the second cavity 1.4, and the top wall of the corresponding housing above the first cavity 1.3 is provided with There is a first jet actuator outlet channel 1.5, and a second jet actuator outlet channel 1.6 is provided on the corresponding top wall of the casing above the second cavity 1.4.

[0031] The vibrating membrane 1.2 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com