Heat-resistant and anti-crystal transition HNIW (hexanitrohexaazaisowurtzitane)-based mixed explosive and preparation method thereof

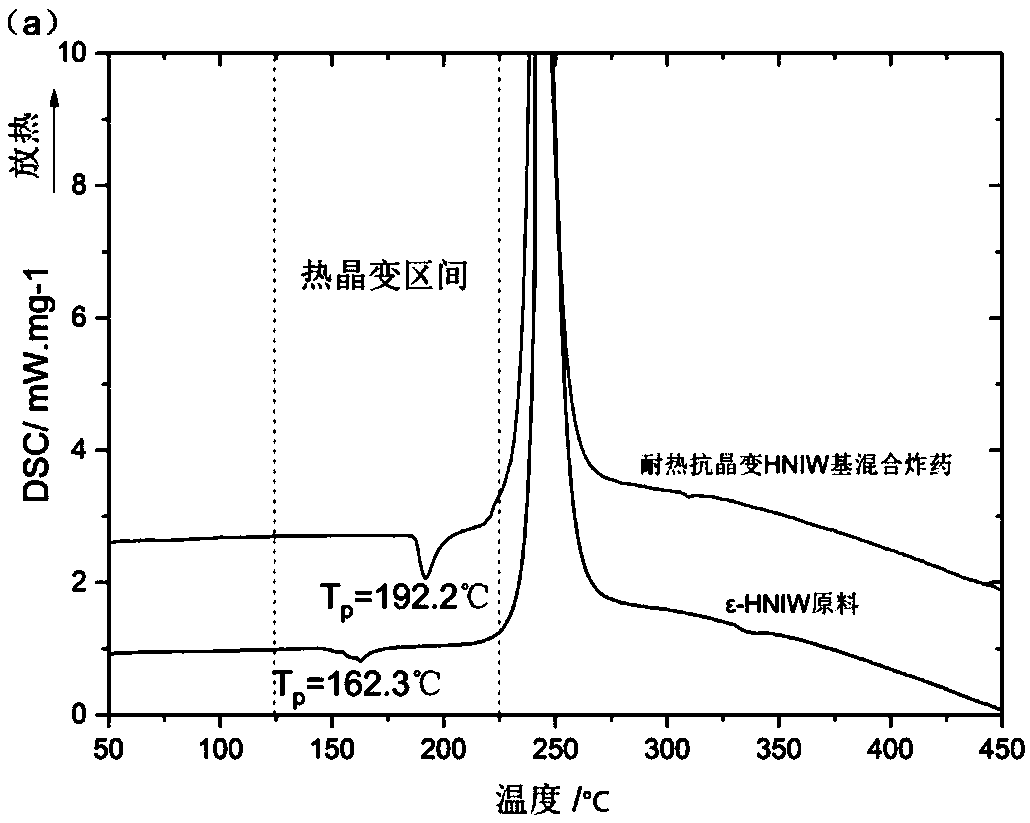

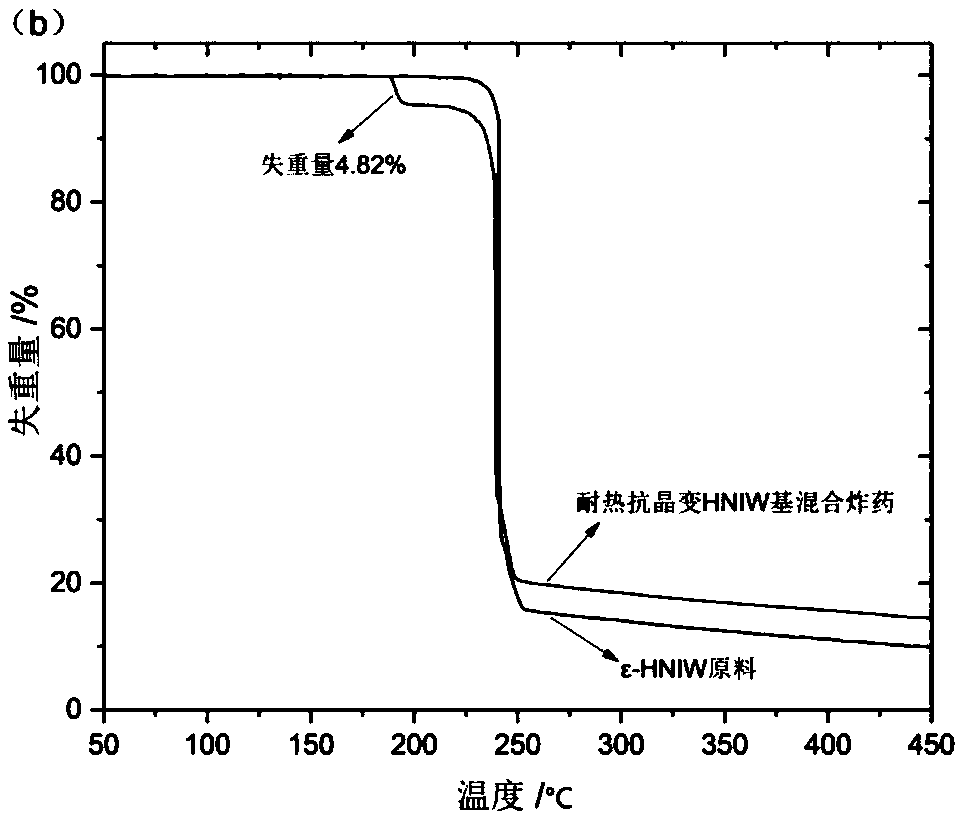

A technology of mixed explosives and crystal transformation, which is applied in explosives processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., which can solve the problems of poor bearing capacity, structural and functional degradation, and decreased workability, etc. problem, to achieve the effect of increasing the crystal transformation temperature, promoting application, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

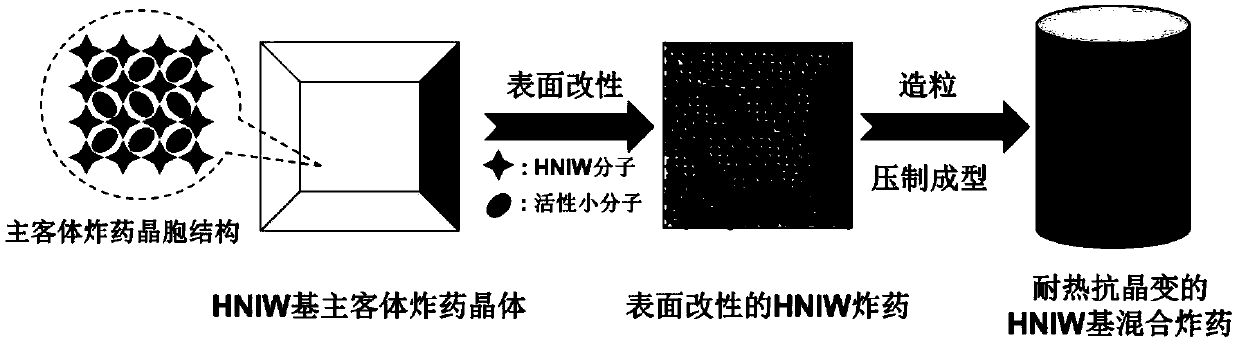

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 0.446g of Tris salt and place it in a 250ml Erlenmeyer flask, measure 180ml of deionized water and 36ml of ethanol to dissolve, then add 0.27g of dopamine hydrochloride, and magnetically force it at a rate of 300r / min Stir until completely dissolved.

[0027] (2) Weigh 10g of unit cell embedded N 2 Add the HNIW-based host-guest explosive crystal of O molecules into the dopamine solution in step 1, and continue magnetic stirring for 24 hours to make dopamine in-situ polymerize on the crystal surface to form a dense coating layer, then filter, wash, and dry to obtain the surface-modified HNIW-based explosive crystal. Host-guest explosive crystals.

[0028] (3) Weigh 0.8g of polyurethane into a 150ml Erlenmeyer flask, add 50ml of chloroform, heat to 50°C, and magnetically stir at 300r / min until the polyurethane is completely dissolved.

[0029] (4) Add the surface-modified HNIW-based host-guest explosive crystal prepared in step 2 into the solution, continue ma...

Embodiment 2

[0032] (1) Weigh 0.5g of polydopamine nanoparticles into a 150ml Erlenmeyer flask, add 100ml of deionized water and stir magnetically at a rate of 400r / min to fully disperse the particles.

[0033] (2) Weigh 10g of unit cell embedded NO 2 Molecular HNIW-based host-guest explosive crystals are added to the polydopamine solution in step 1, and magnetic stirring is continued for 24 hours to allow the particles to aggregate on the crystal surface to form a dense coating layer, and then filtered, washed, and dried to obtain surface-modified HNIW-based host-guest Dynamite crystals.

[0034] (3) Weigh 1g of fluororubber into a 150ml Erlenmeyer flask, add 50ml of carbon tetrachloride, heat to 70°C, and magnetically stir at 200r / min until the fluororubber is completely dissolved.

[0035] (4) Add the surface-modified HNIW-based host-guest explosive crystal prepared in step 2 into the solution, continue magnetic stirring, use a vacuum pump to continuously pump air to volatilize the sol...

Embodiment 3

[0038] (1) Weigh 0.446g of Tris salt and place it in a 250ml Erlenmeyer flask, measure 180ml of deionized water and 36ml of ethanol to dissolve, then add 0.27g of dopamine hydrochloride, and magnetically force it at a rate of 600r / min Stir until completely dissolved.

[0039] (2) Weigh 10 g of HNIW-based host-guest explosive crystals with NO molecules embedded in the unit cells and add them to the dopamine solution in step 1, and continue magnetic stirring for 24 hours to make dopamine polymerize in situ on the crystal surface to form a dense coating layer, then filter, After washing and drying, surface-modified HNIW-based host-guest explosive crystals are obtained.

[0040] (3) Weigh 0.4g of styrene-butadiene rubber into a 150ml Erlenmeyer flask, add 50ml of chloroform, heat to 40°C, and magnetically stir at 600r / min until the polyurethane is completely dissolved.

[0041] (4) Add the surface-modified HNIW-based host-guest explosive crystal prepared in step 2 into the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com