A LTCC substrate three-dimensional stacking structure and a hermetic packaging method thereof

A three-dimensional stacking and hermetic packaging technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of inability to achieve airtightness, complicated process, and many welding gradients, and achieve strong airtight reworkability and process Simple process, scientific and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

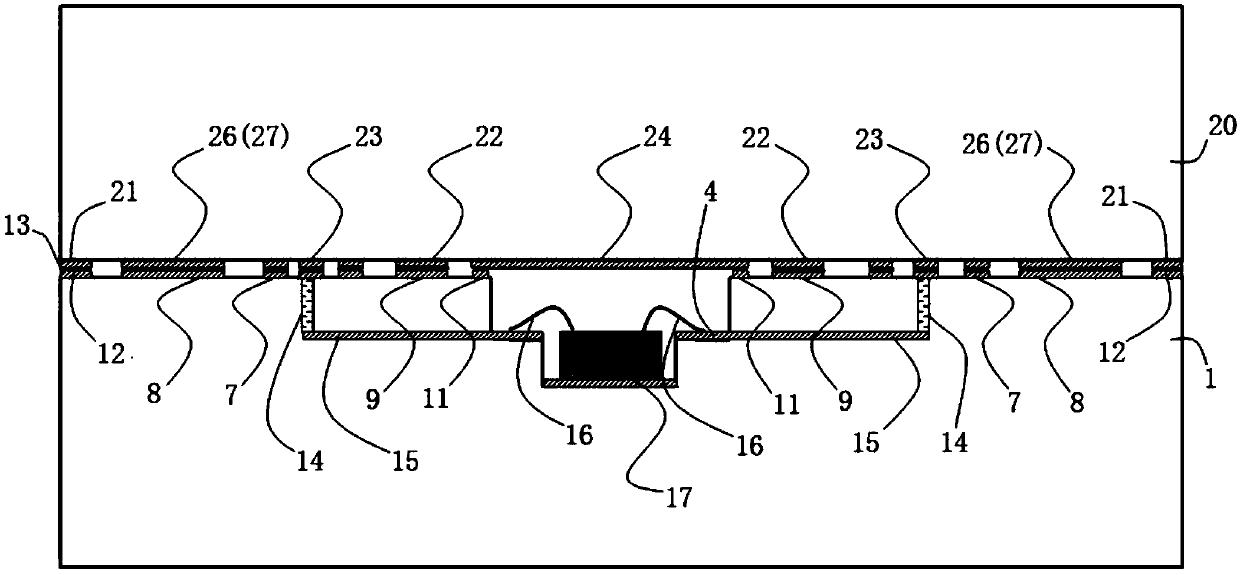

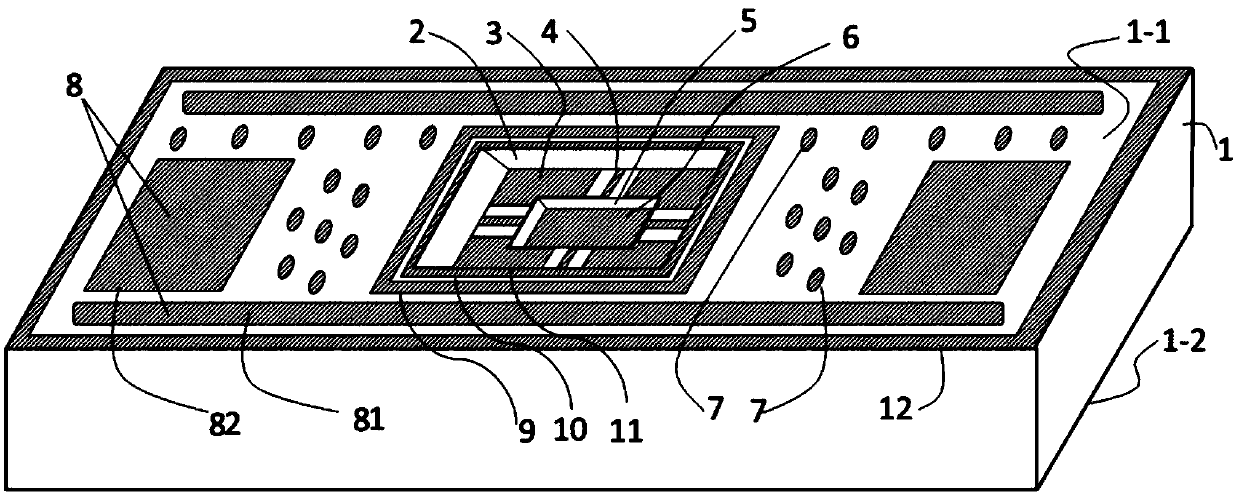

[0047] Such as Figure 1-6 As shown, the three-dimensional stacked structure of LTCC substrates provided by the present invention has scientific and reasonable design, simple structure, and is convenient to use. Integration provides a simple, reliable solution. The three-dimensional stacked structure of LTCC substrates of the present invention includes a first LTCC substrate 1 on which components 17 are placed, and a second LTCC substrate 20 hermetically sealed on the top surface of the first LTCC substrate 1 .

[0048] The top surface of the first LTCC substrate 1 of the present invention is provided with a cavity for placing components 17, the top surface of the cavity is open, and the top surface of the first LTCC substrate 1 is arranged around the opening of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com