Electric-chemical combined remediation system and method for organic matter polluted soil

A technology of joint restoration of contaminated soil, applied in the field of electro-chemical joint restoration system, can solve the problems of insufficient contact between pollutants and agents, short effective action time of agents, and small soil permeability coefficient, so as to improve restoration efficiency and shorten construction period , Repair the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

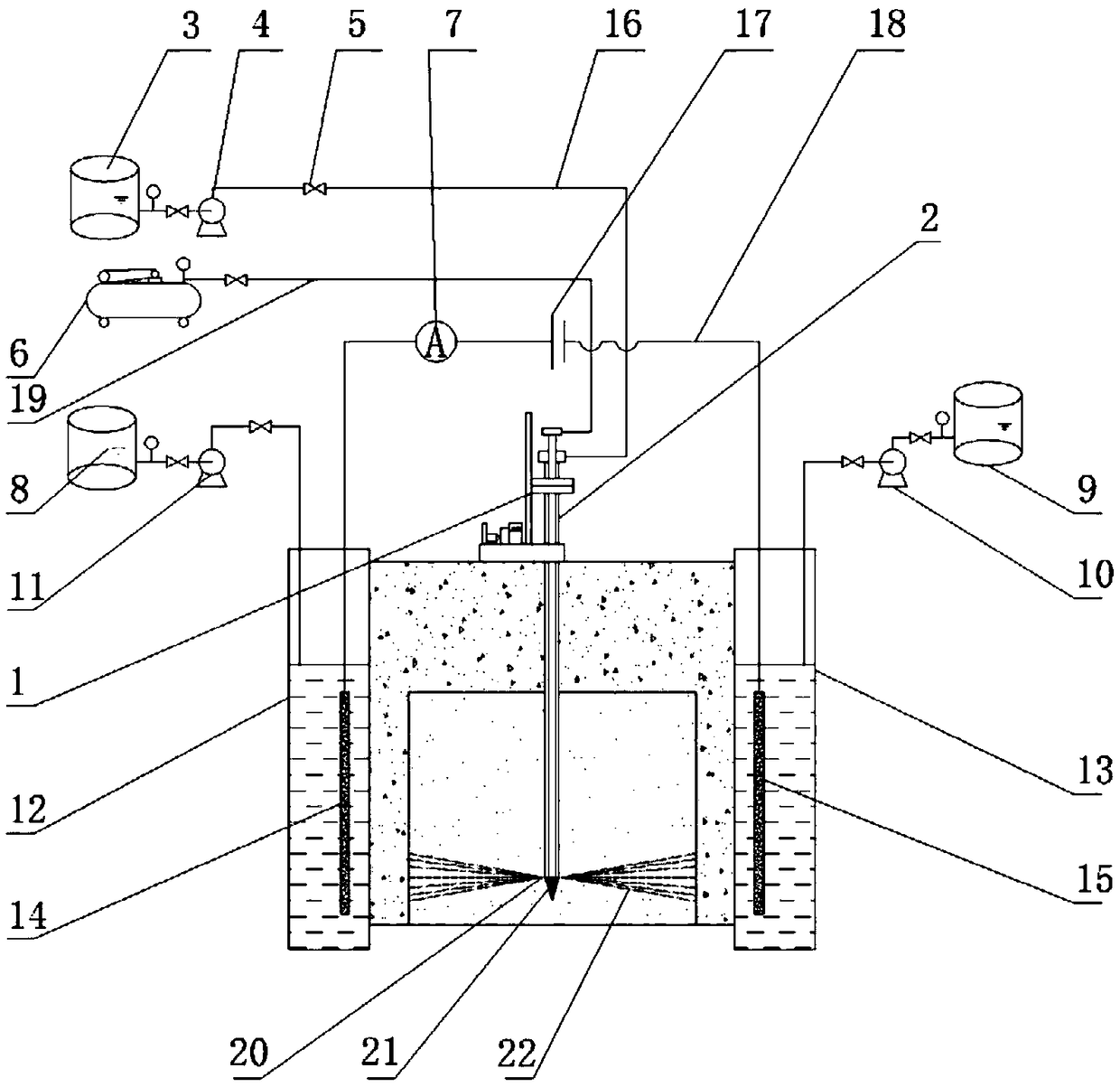

[0051] This embodiment provides an electro-chemical combined remediation system for soil contaminated by organic matter. The schematic structural diagram of the system is as figure 1 Shown from figure 1 It can be seen that the system includes a medicine mixing unit, a high-pressure injection unit and an electrochemical unit;

[0052] Wherein, the medicine mixing unit includes a medicine mixing tank 3, a high-pressure delivery pump 4, a shut-off valve 5, a pressure gauge and a liquid flow sensor (not shown in the figure); the medicine mixing tank 3 is provided with an electric stirrer;

[0053] The high-pressure jet unit includes a drill (such as an Eprobe environmental drill) 1, a hollow drill rod 2 and an air compressor 6; the drill 1 is connected to the hollow drill rod 2, and the bottom end of the hollow drill rod 2 is connected by internal threads There is a drill bit 21, the two sides of the drill bit 21 are fixedly connected with nozzles 20 through threads, and the bottom of t...

Embodiment 2

[0063] This embodiment provides an electrokinetic-chemical joint remediation method for organic matter-contaminated soil, which is implemented using the electrokinetic-chemical joint remediation system for organic matter-contaminated soil provided in Example 1. The method specifically includes the following steps:

[0064] (1) Take a silt soil block contaminated by chlorobenzene (including 1,4-dichlorobenzene and chlorobenzene) as an example. The contaminated land area is 1,800 square meters, the pollution depth is 5m, and the total repair volume is 2200 square. Divide the contaminated land into two parts, A and B. Part A performs the electro-chemical combined repair provided by the present invention, and part B only performs chemical repair;

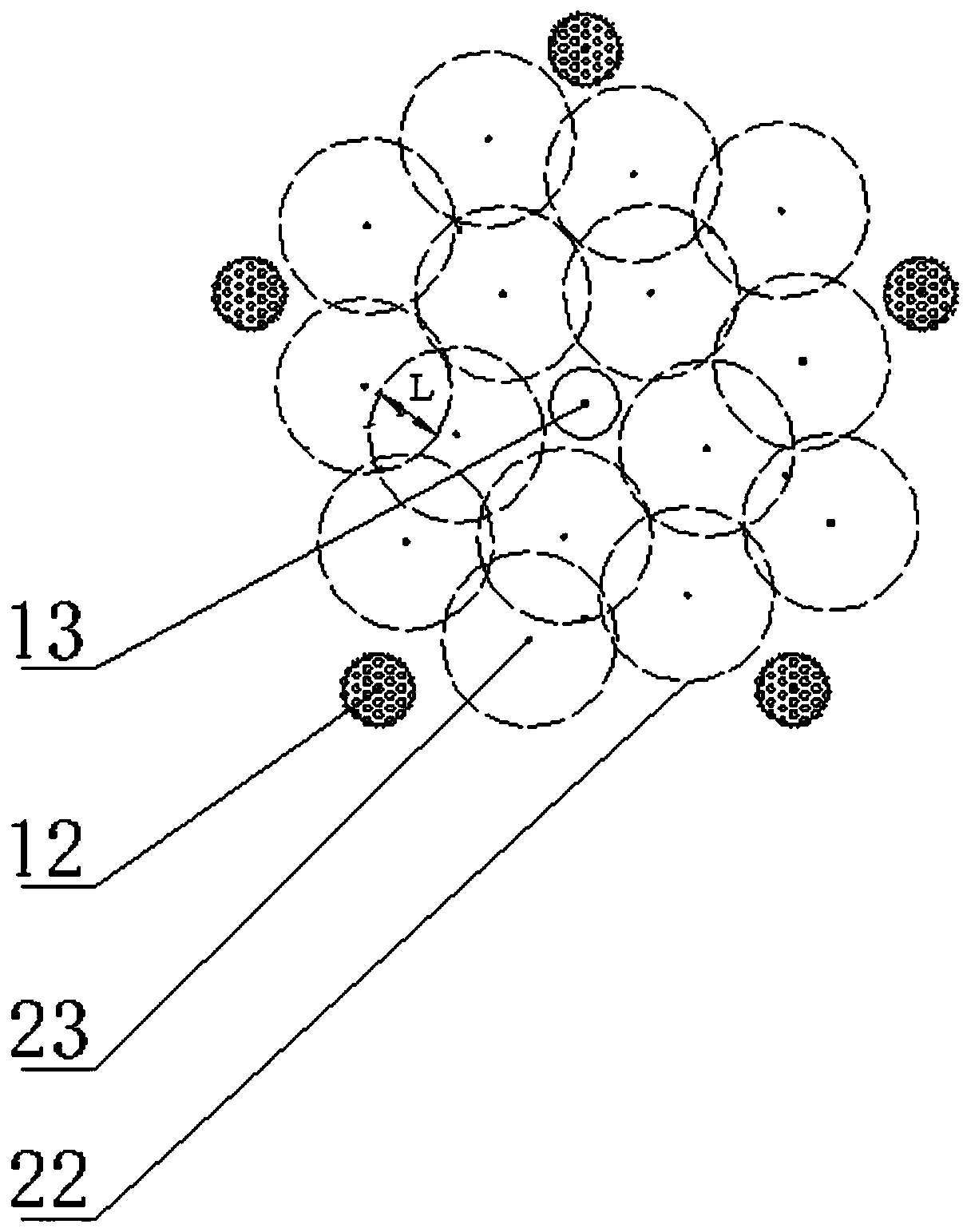

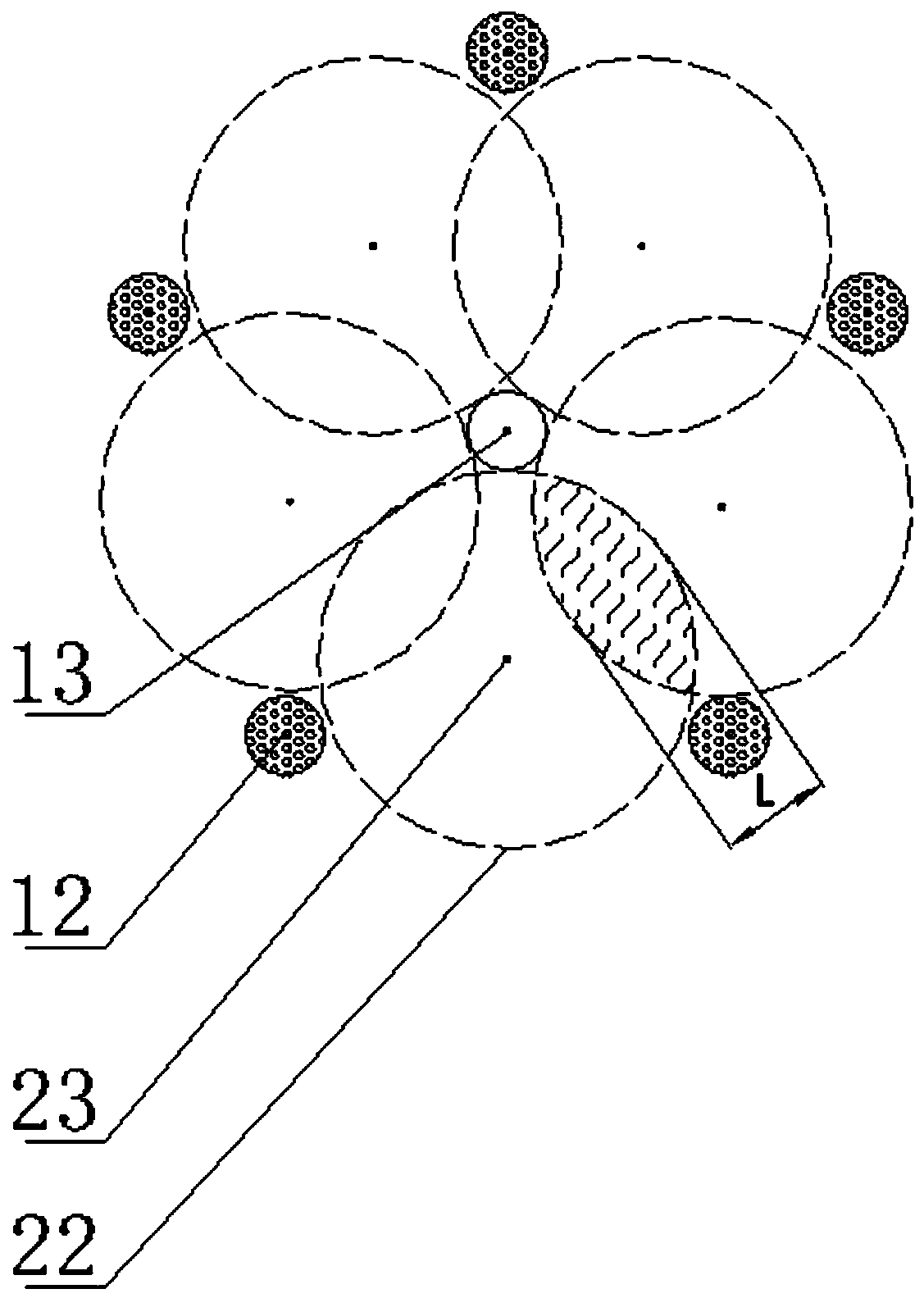

[0065] Take samples at 2m, 3m, 4m, and 5m respectively, and determine that the depth of the high-pressure spraying point is 6m, the spraying radius is 3m, and the amount of earthwork covered by a single injection is about 140 square meters. ...

Embodiment 3

[0077] This embodiment provides an electrokinetic-chemical joint remediation method for organic matter-contaminated soil, which is implemented using the electrokinetic-chemical joint remediation system for organic matter-contaminated soil provided in Example 1. The method specifically includes the following steps:

[0078] (1) Take a silt soil block contaminated by chlorobenzene (including 1,4-dichlorobenzene and chlorobenzene) as an example. The contaminated land area is 1,800 square meters, the pollution depth is 5m, and the total repair volume is 2200 square. The contaminated land is divided into two parts, A and B. Part A performs the electro-chemical combined repair provided by the present invention, and part B only performs chemical repair.

[0079] Samples were taken at 2m, 3m, 4m, and 5m respectively to determine that the depth of the high-pressure spraying point was 6m, the spraying radius was 5m, and the amount of earthwork covered by a single injection was about 400 cubi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com