Machining method for neodymium iron boron inclined tile magnetic sheets

A processing method, NdFeB technology, applied in the manufacture of stator/rotor bodies, motor generators, electrical components, etc., can solve the problems of waste of blanks, slow processing speed, high cost, etc., to increase accuracy and improve production efficiency , Guarantee the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

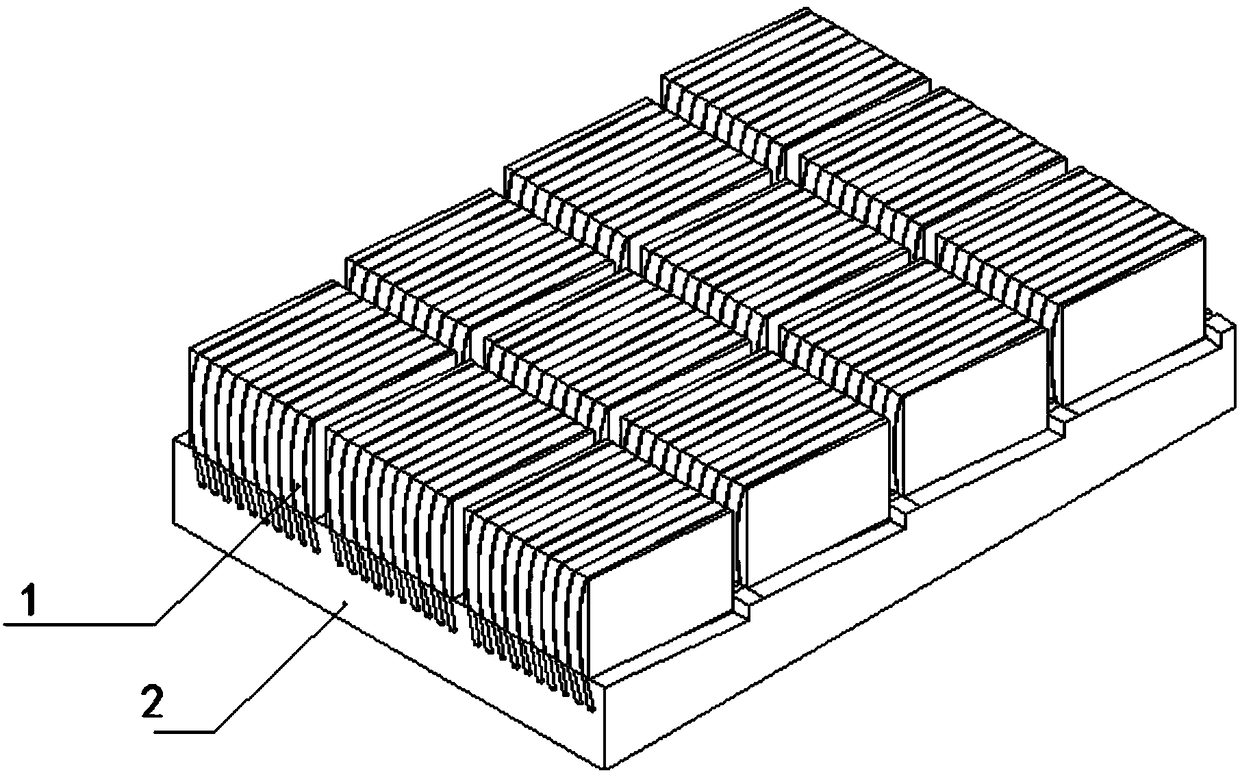

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

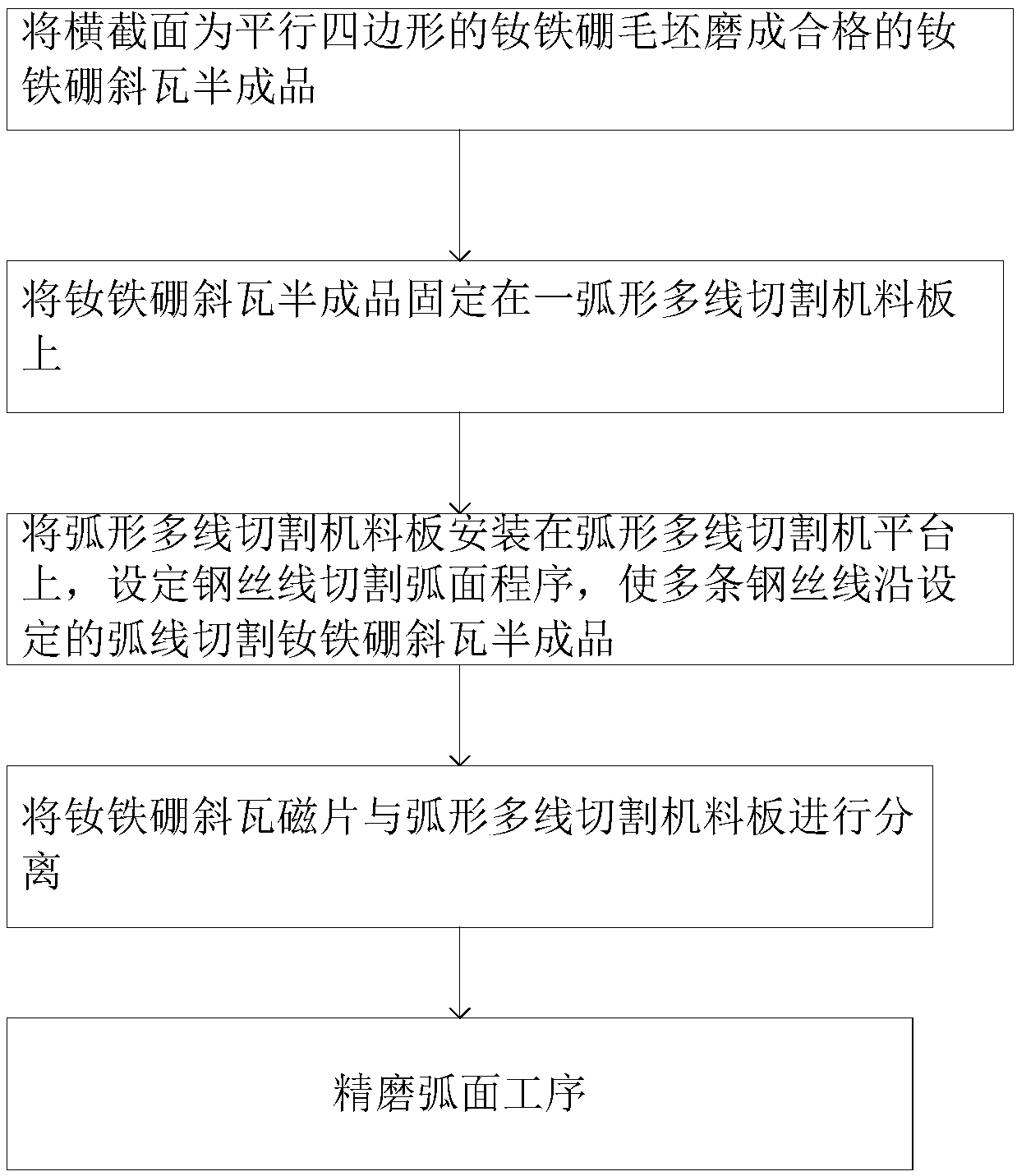

[0033] like figure 1 As shown, the processing method of the NdFeB slope tile magnetic sheet provided by the embodiment of the present invention includes:

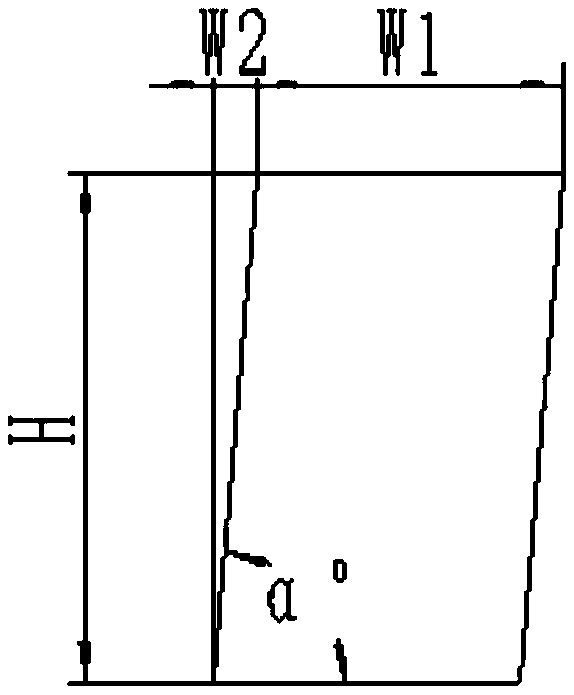

[0034] Step 1. Grinding NdFeB blanks with a parallelogram in cross section into qualified NdFeB slope tile semi-finished products, the cross section of the NdFeB slope tile semi-finished products is also a parallelogram, and one of the included angles is α°, 60 ≦α≦89;

[0035] In the first step, the NdFeB blank with a parallelogram in cross section is ground into a NdFeB inclined tile semi-finished product with a parallelogr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com