Novel die-cast type tray

A pallet, a new type of technology, applied in the field of cargo transportation pallets, can solve the problems of small load, poor temperature resistance, low strength of injection molded pallets, etc., and achieve the effects of less space occupation, poor volatility, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

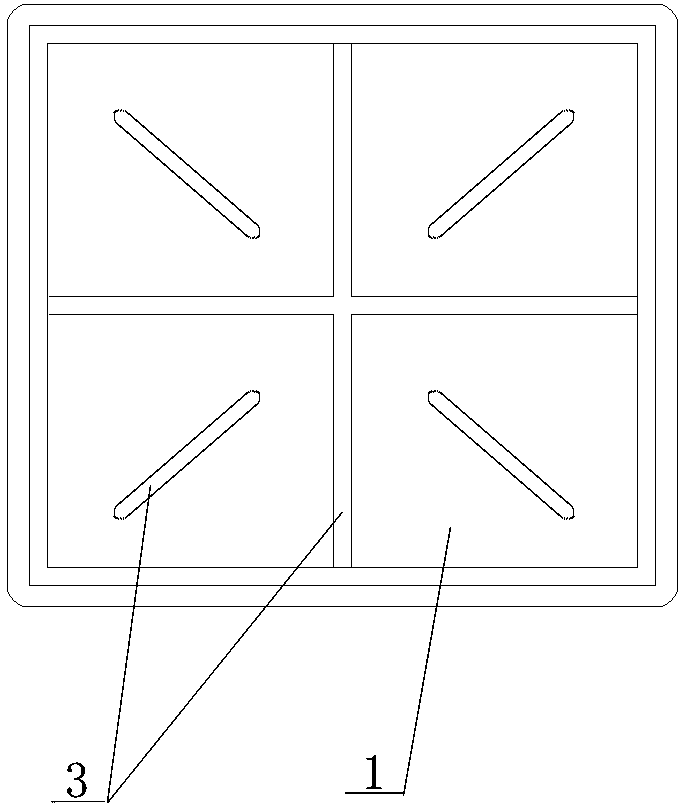

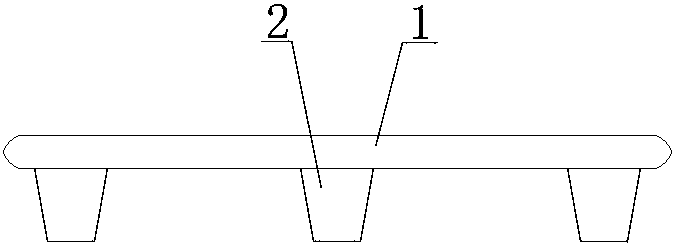

[0047] Refer to attached figure 1 to attach Figure 4 , a novel die-casting tray, which includes a support plate 1;

[0048] The bottom surface of the support plate 1 is evenly provided with a number of support legs 2; the support plate 1 is evenly provided with a number of reinforcing ribs 3;

[0049] The support plate 1, support legs 2 and reinforcing ribs 3 are integral die-casting structures.

[0050] In order to improve the overall strength, the supporting legs 2 are all solid structures.

[0051] The novel die-casting tray is prepared from the following raw materials in parts by weight:

[0052] 100 parts of automotive interior scraps, 30 parts of straw powder and 1 part of coupling agent;

[0053] The components of the automobile interior scraps are as follows in weight percent: PET20%, PP20%, PA10%, PPR5%, PE10%, PVC3%, hemp fiber 12%, coconut palm fiber 10%, glass fiber 5%, wood fiber 4% and impurities 1%.

Embodiment 2

[0065] Refer to attached figure 1 to attach Figure 4 , a novel die-casting tray, which includes a support plate 1;

[0066] The bottom surface of the support plate 1 is evenly provided with a number of support legs 2; the support plate 1 is evenly provided with a number of reinforcing ribs 3;

[0067] The support plate 1, support legs 2 and reinforcing ribs 3 are integral die-casting structures.

[0068] In order to improve the overall strength, the supporting legs 2 are all solid structures.

[0069] The novel die-casting tray is prepared from the following raw materials in parts by weight:

[0070] 200 parts of automotive interior scraps, 50 parts of straw powder and 2 parts of coupling agent;

[0071] The components of the automobile interior scraps are as follows in weight percent: PET20%, PP20%, PA10%, PPR5%, PE10%, PVC3%, hemp fiber 12%, coconut palm fiber 10%, glass fiber 5%, wood fiber 4% and impurities 1%.

[0072] The stalk powder is corn stalk powder, specifi...

Embodiment 3

[0083] Refer to attached figure 1 to attach Figure 4 , a novel die-casting tray, which includes a support plate 1;

[0084] The bottom surface of the support plate 1 is evenly provided with a number of support legs 2; the support plate 1 is evenly provided with a number of reinforcing ribs 3;

[0085] The support plate 1, support legs 2 and reinforcing ribs 3 are integral die-casting structures.

[0086] In order to improve the overall strength, the supporting legs 2 are all solid structures.

[0087] The novel die-casting tray is prepared from the following raw materials in parts by weight:

[0088] 150 parts of automotive interior scraps, 40 parts of straw powder and 1 part of coupling agent;

[0089] The components of the automobile interior scraps are as follows in weight percent: PET20%, PP20%, PA10%, PPR5%, PE10%, PVC3%, hemp fiber 12%, coconut palm fiber 10%, glass fiber 5%, wood fiber 4% and impurities 1%.

[0090] The straw powder is preferably corn straw powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com