A green method for preparing calcium hydroxyphosphate nanorods

A technology of calcium hydroxyphosphate and nanorods, applied in the preparation of calcium hydroxyphosphate nanorods, in the field of preparation of calcium hydroxyphosphate nanorods, can solve the problems of low biocompatibility, too large crystal grains, complicated operation, etc., and achieve easy operation , large aspect ratio and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

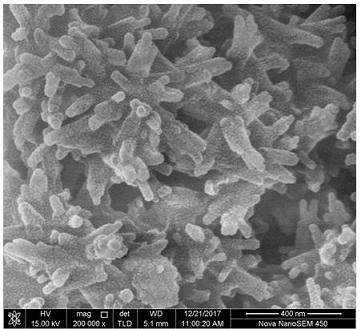

[0012] In a 100 L hydrothermal reactor, add 3.27 kg of calcium sulfate dihydrate, 6.54 kg of sodium phosphate dodecahydrate and 73.5 kg of distilled water in sequence, mix well and heat. From room temperature to 170°C, keep the reaction for 6 h. After the reaction was completed, it was cooled to room temperature, the product was filtered, washed with distilled water three times, and dried at 105 °C for 1 h to obtain calcium hydroxyphosphate nanorods. The diameter of calcium hydroxyphosphate nanorods is 40 nm to 70 nm, the length is 160 nm to 240 nm, the aspect ratio is 2.3 to 6.0, and the yield is 98%.

Embodiment 2

[0014] In a 100 L hydrothermal reactor, add 3.27 kg of calcium sulfate dihydrate, 6.23 kg of sodium phosphate dodecahydrate and 70.0 kg of distilled water in sequence, mix well and heat. From room temperature to 180°C, keep the reaction for 5 h. After the reaction was completed, it was cooled to room temperature, the product was filtered, washed with distilled water three times, and dried at 105 °C for 1 h to obtain calcium hydroxyphosphate nanorods. The diameter of calcium hydroxyphosphate nanorods is 40 nm to 70 nm, the length is 160 nm to 240 nm, the aspect ratio is 2.3 to 6.0, and the yield is 97%.

Embodiment 3

[0016] In a 100 L hydrothermal reaction kettle, add 3.27 kg of calcium sulfate dihydrate, 6.85 kg of sodium phosphate dodecahydrate and 77.0 kg of distilled water in sequence, mix well and heat. From room temperature to 160°C, keep the reaction for 7 h. After the reaction was completed, it was cooled to room temperature, the product was filtered, washed with distilled water three times, and dried at 105 °C for 1 h to obtain calcium hydroxyphosphate nanorods. The calcium hydroxyphosphate nanorods have a diameter of 40 nm to 70 nm, a length of 160 nm to 240 nm, an aspect ratio of 2.3 to 6.0, and a yield of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com