A kind of dispersing resin for general color paste of coil coating and preparation method thereof

A technology of coil coating and dispersing resin, applied in the direction of pigment slurry, etc., can solve the problems of affecting the appearance of paint film, difficulty in management, increase in inventory, etc., and achieve the effect of high molecular branching degree and good dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

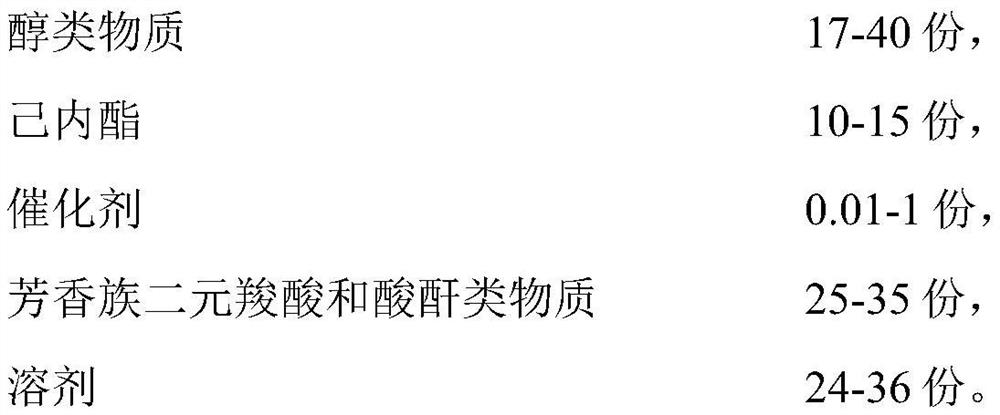

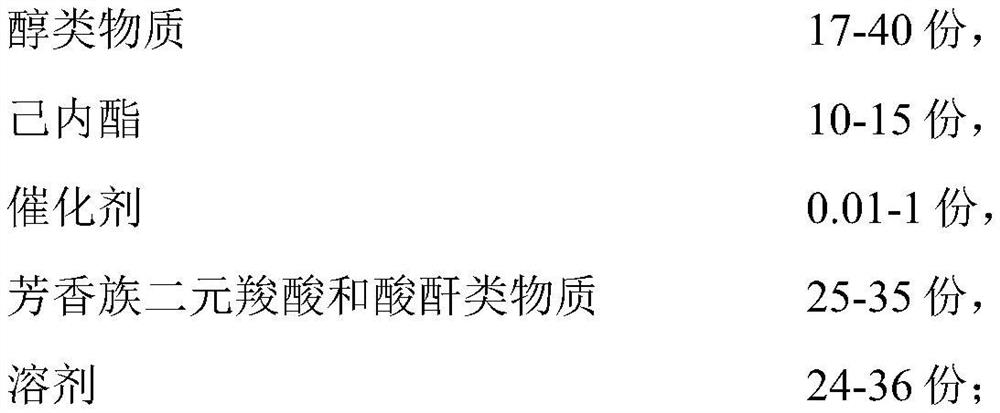

Method used

Image

Examples

Embodiment 1

[0033] According to the formula in Table 1, add 1-6-hexanediol to the reaction kettle, heat and dissolve it, add caprolactone, neopentyl glycol and start stirring, add pentaerythritol, n-butyl titanate, terephthalate successively Formic acid and phthalic anhydride, the temperature when adding n-butyl titanate should be below 100 °C, and the material should be slowly heated to 215 °C within 1-3 hours; confirm that the reactant is in a transparent state, and keep the temperature at 215 Continue the reaction at -220 °C. In order to prevent coloration, this temperature range must be strictly observed. Starting from the temperature reaching 215 °C, sampling is carried out every 1 hour. When the acid value is below 20 mgKOH / g, sampling is carried out every 30 minutes.

[0034] Dilute the sample according to the following formula, measure the acid value and viscosity, and configure the sample according to the following ratio for viscosity test:

[0035] Sampling 20.0 parts by weight;...

Embodiment 2

[0039] According to the formula in Table 1, add 1-6-hexanediol to the reaction kettle, heat and dissolve it, add caprolactone, neopentyl glycol and start stirring, add pentaerythritol, n-butyl titanate, terephthalate successively Formic acid and phthalic anhydride, the temperature when adding n-butyl titanate should be below 100 °C, and the material should be slowly heated to 215 °C within 1-3 hours; confirm that the reactant is in a transparent state, and keep the temperature at 215 Continue the reaction at -220 °C. In order to prevent coloration, this temperature range must be strictly observed. Starting from the temperature reaching 215 °C, sampling is carried out every 1 hour. When the acid value is below 20 mgKOH / g, sampling is carried out every 30 minutes.

[0040] Dilute the sample according to the following formula, measure the acid value and viscosity, and configure the sample according to the following ratio for viscosity test:

[0041] Sampling 20.0 parts by weight;...

Embodiment 3

[0045]According to the formula in Table 1, add 1-6-hexanediol to the reaction kettle, heat and dissolve it, add caprolactone, neopentyl glycol and start stirring, add pentaerythritol, n-butyl titanate, terephthalate successively Formic acid and phthalic anhydride, the temperature when adding n-butyl titanate should be below 100 °C, and the material should be slowly heated to 215 °C within 1-3 hours; confirm that the reactant is in a transparent state, and keep the temperature at 215 Continue the reaction at -220 °C. In order to prevent coloration, this temperature range must be strictly observed. Starting from the temperature reaching 215 °C, sampling is carried out every 1 hour. When the acid value is below 20 mgKOH / g, sampling is carried out every 30 minutes.

[0046] Dilute the sample according to the following formula, measure the acid value and viscosity, and configure the sample according to the following ratio for viscosity test:

[0047] Sampling 20.0 parts by weight; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com