InP quantum dot and preparation method thereof

A technology of quantum dots and ligands, applied in the field of quantum dot preparation, can solve the problems of large half-peak width, difficult control of the nucleation and growth process of InP quantum dots, and difficulty in controlling the emission wavelength of InP quantum dots. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present application provides a method for preparing InP quantum dots, including: step S1: at 100-150°C, add PH to the mixed system containing indium precursor, first ligand and first organic solvent 3 , to obtain a nanocrystal nucleus solution; step S2: cooling the nanocrystal nucleus solution in step S1 to 0-60° C., adding a second ligand to obtain a nanocrystal nucleus solution modified by a second ligand; step S3: converting step S2 The temperature of the nano crystal core solution modified by the second ligand is raised to 200-300° C., and the precursor required for the synthesis of the shell layer is added to obtain InP quantum dots with the shell layer.

[0024] As a gaseous material, PH 3 Gases are generally liquefied and compressed in cylinders. In this application, PH 3 The gas can be directly passed into the mixed system in the form of gas, or the pH 3 After the gas is dispersed in an organic solvent, it is added to the mixing system in the form of a ga...

Embodiment 1

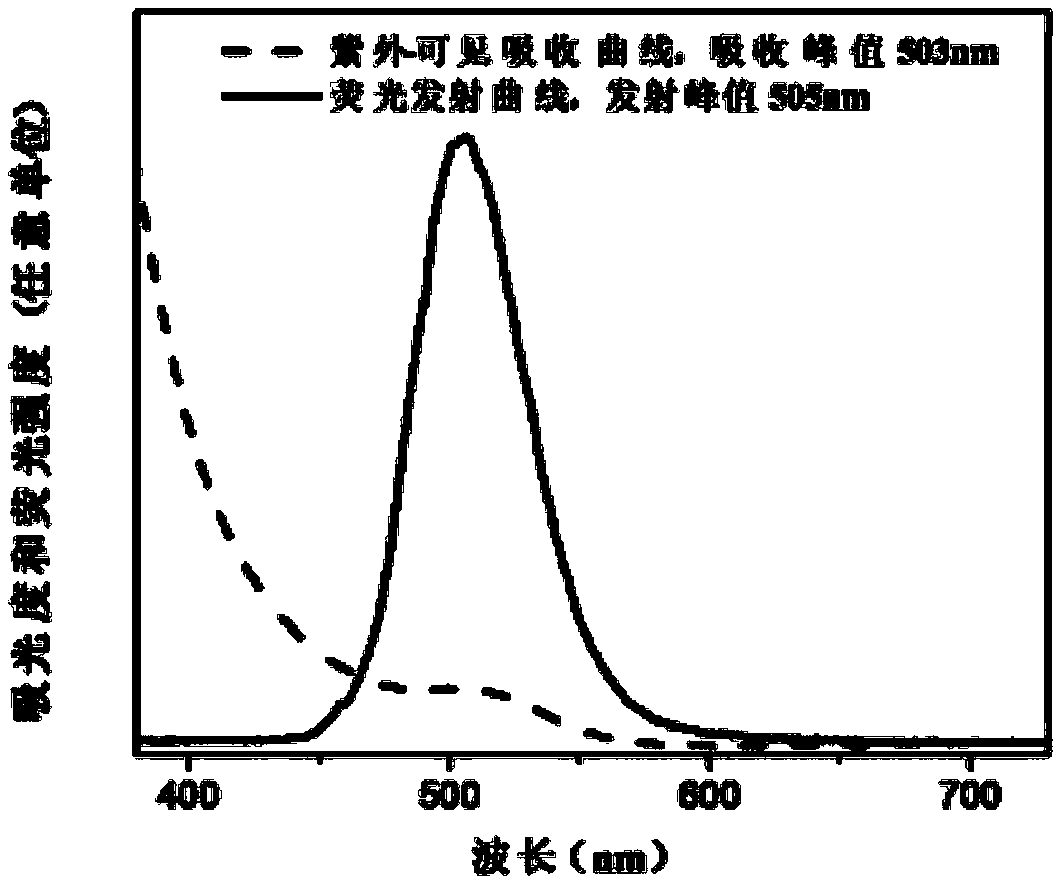

[0040] Add 294 mg of indium acetate, 183 mg of zinc acetate, 1 mL of oleic acid, and 20 mL of 1-octadecene into a three-necked flask, and heat to dissolve under a nitrogen atmosphere. The temperature of the solution was raised to 130°C, and the pH 3 Gas reaction for 5 minutes, until the color of the solution is darkened to light yellow, quickly cool down to 20°C, add 0.5mL of n-dodecylmercaptan, keep warm for 10min, quickly heat up to 280°C, then add 1g of zinc stearate to the solution, ( Zinc stearate was dissolved in 5 mL of 1-octadecene), and kept warm for 1 h, then 0.5 mL of n-dodecanethiol was added, kept warm for 2 h, and the heating was stopped. figure 1 It is the ultraviolet-visible absorption and fluorescence emission spectrogram of the sample prepared in embodiment 1, from figure 1 It can be seen that its emission peak is 505nm, its absorption peak is 503nm, and its half-width is less than 60nm.

Embodiment 2

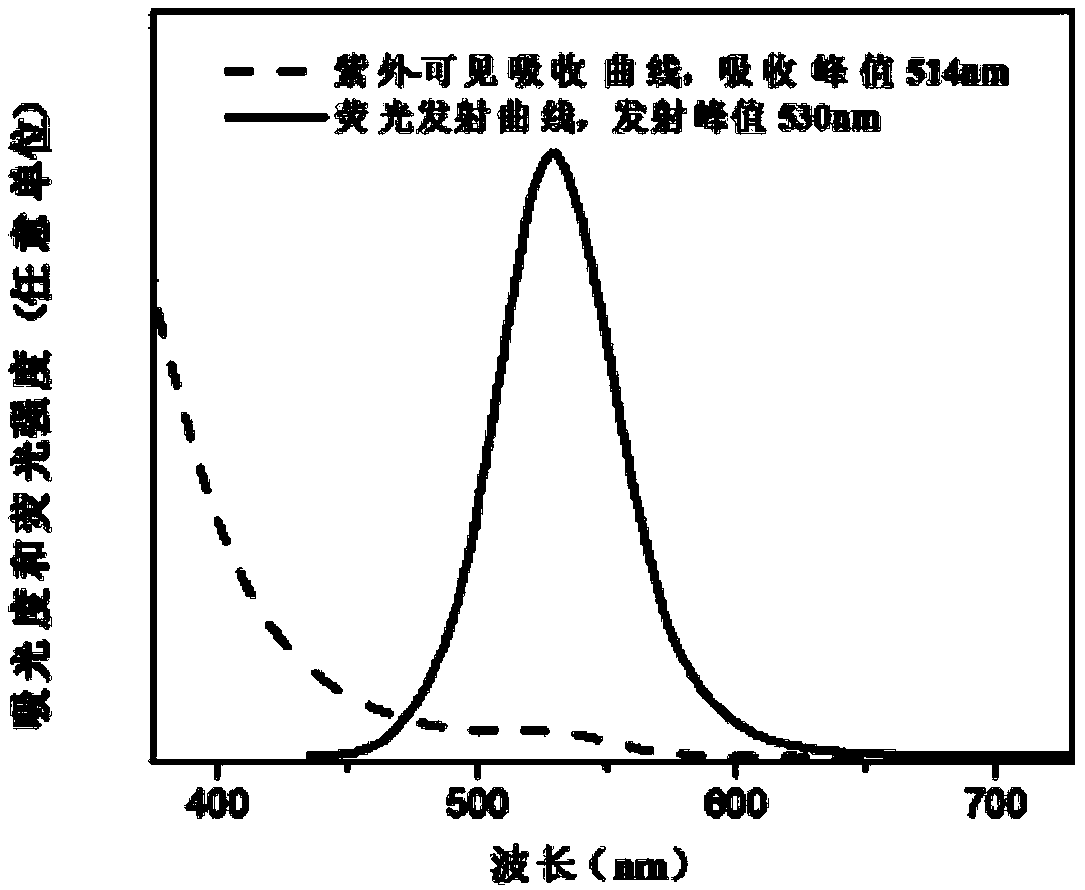

[0042] Add 294mg of indium acetate, 90mg of zinc acetate, 0.8mL of oleic acid and 20mL of 1-octadecene into a three-necked flask, and heat to dissolve under a nitrogen atmosphere. The temperature of the solution was raised to 130°C, and the pH 3 Gas reaction for 20 minutes, when the color of the solution is darkened to light yellow, quickly cool down to 20°C, add 0.5mL of oleylamine, keep it warm for 10min, quickly raise the temperature to 220°C, then add 0.5mL of trioctylphosphine solution of elemental sulfur to the solution (2M), keep warm for 30min, heat up to 240°C, add 2mL of 0.5M 1-octadecene solution of zinc oleate to the solution, keep warm for 30min, heat up to 260°C, add 0.5mL of elemental sulfur to the solution Trioctylphosphine solution (2M), keep warm for 30min, stop heating. figure 2 It is the ultraviolet-visible absorption and fluorescence emission spectrogram of the sample prepared in embodiment 2, from figure 2 It can be seen that its emission peak is 530n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com