Polyparaphenylene vinylene conjugated polymer fluorescent nanoparticles with controllable emission wavelength and preparation method

A technology of phenylene vinylene and conjugated polymers, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as difficult dissolution, unsatisfactory polymer solution, poor solubility of PPV polymers, etc., and achieve emission Wavelength controllable, easy to operate, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

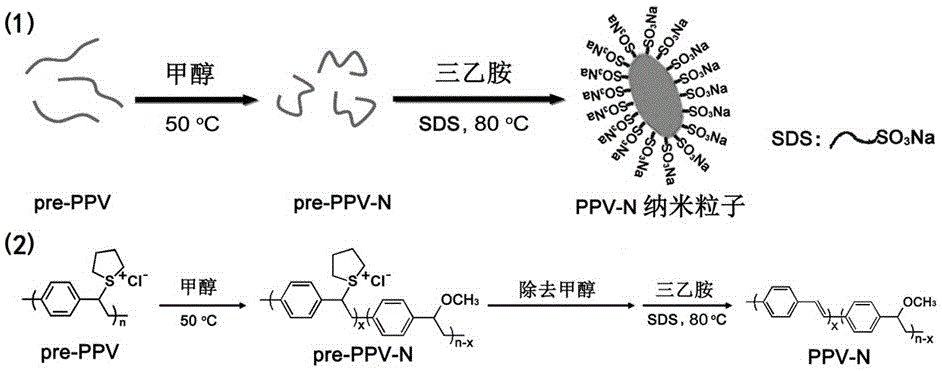

[0030] See attached figure 1 , which is a schematic diagram of the preparation route of poly(p-phenylenevinylene) conjugated polymer nanoparticles provided in this example, and the specific steps are as follows:

[0031] 1. Refer to the literature (J. Am. Chem. Soc.1993, 115, 10117-10124) to synthesize PPV monomers containing unsubstituted benzene rings, take 0.6895 g (1.965 mmol) of PPV monomers, under anhydrous and oxygen-free conditions Dissolve the prepared PPV monomer in 12mL H 2 O; then 1.7 mL of 1 M NaOH aqueous solution was slowly added dropwise, placed in an ice-water bath and stirred for 1 h, then added 3 mL of 2 M HCl solution to terminate the reaction, and then dialyzed with a dialysis bag with a molecular weight of 3500 After 24 hours (excluding the 12 hours overnight, the water was changed every 2 hours in other time periods, and 500 mL of deionized water was added each time), and 20 mL of PPV precursor (referred to as pre-PPV) solution was obtained.

[0032] 2...

Embodiment 2

[0036] 1. Dissolve 0.6895 g (1.965 mmol) of PPV monomer containing unsubstituted benzene ring synthesized by reference (J. Am. Chem. Soc.1993, 115, 10117-10124) in 12 mL h 2 Then, 1.7 mL of 1 M NaOH aqueous solution was slowly added dropwise, placed in an ice-water bath and stirred for 1 h, then 3 mL of 2 M HCl solution was added to terminate the reaction, and then dialyzed with a dialysis bag with a molecular weight of 3500 After 24 hours (excluding the 12 hours overnight, the water was changed every 2 hours in other time periods, and 500 mL of deionized water was added each time), and 20 mL of PPV precursor solution was obtained. Add 5 ml of the obtained solution into an oxygen-free 250 mL two-neck flask, then add 15 ml of deionized water for dilution, then add 60 ml of methanol and mix thoroughly, heat up to 50 °C, and react for 16 h. After the reaction was completed, under reduced pressure, the temperature of the water bath was controlled at 35 °C, and the methanol was re...

Embodiment 3

[0039] 1. Dissolve 0.6895 g (1.965 mmol) of PPV monomer containing unsubstituted benzene ring synthesized by reference (J. Am. Chem. Soc.1993, 115, 10117-10124) in 12 mL h 2 Then, 1.7 mL of 1 M NaOH aqueous solution was slowly added dropwise, placed in an ice-water bath and stirred for 1 h, then 3 mL of 2 M HCl solution was added to terminate the reaction, and then dialyzed with a dialysis bag with a molecular weight of 3500 After 24 hours (excluding the 12 hours overnight, the water was changed every 2 hours in other time periods, and 500 mL of deionized water was added each time), and 20 mL of PPV precursor solution was obtained. Add 5 ml of the obtained solution to an oxygen-free 250 mL two-neck flask, then add 15 ml of deionized water for dilution, then add 60 ml of methanol and mix thoroughly, heat up to 50 °C, and react for 24 h. After the reaction was completed, under reduced pressure, the temperature of the water bath was controlled at 35 °C, and methanol was removed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com