A method of producing gasoline by fractional distillation of crude oil

A crude oil and gasoline technology, which is applied in the processing of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of slow gasoline speed, low work efficiency, and inability to remove water vapor from gasoline, so as to increase speed, save time and save energy. The effect of the time required for crude oil to heat up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

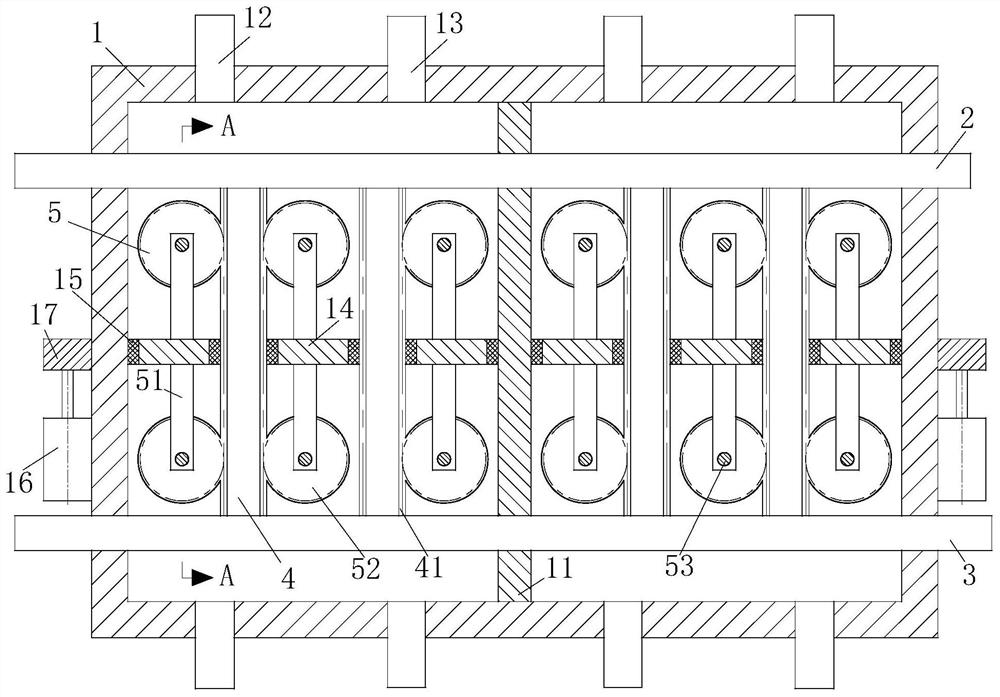

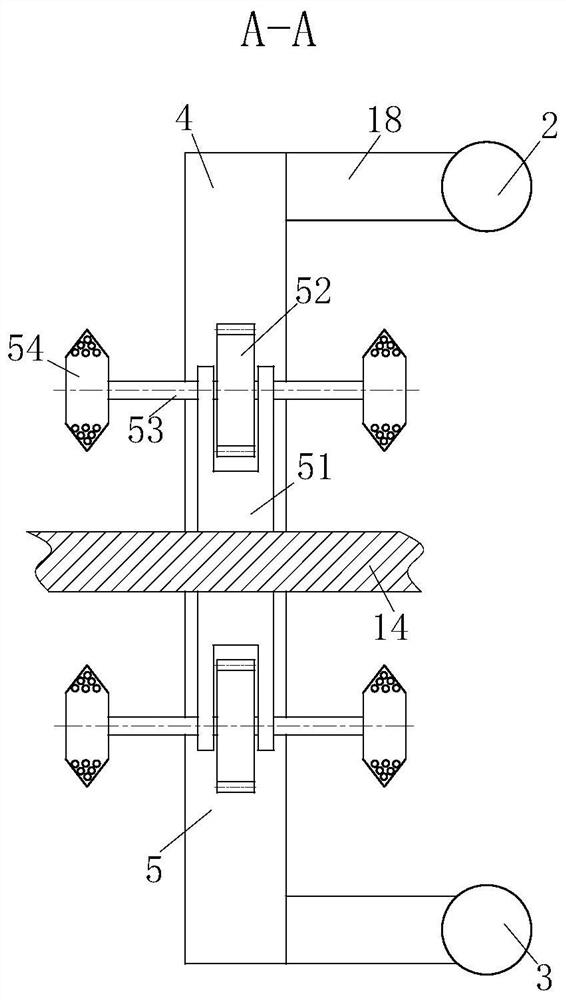

[0026]useFigure 1-Figure 5The method for preparing gasoline by fractional distillation of crude oil according to an embodiment of the present invention will be described as follows.

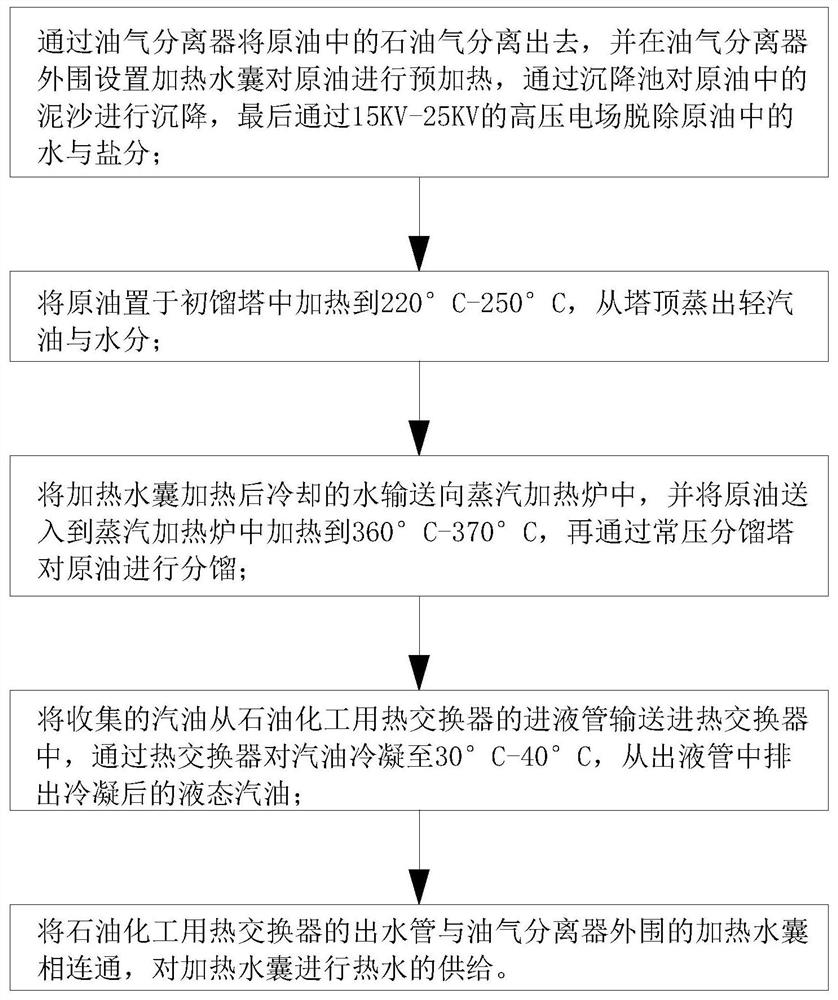

[0027]Such asfigure 1 versusfigure 2 As shown, the method for preparing gasoline by fractionating crude oil according to the present invention includes the following steps:

[0028]S1: Separate the petroleum gas from the crude oil through the oil-gas separator, and set a heating water bladder around the oil-gas separator to preheat the crude oil, shorten the subsequent heating time, and improve the work efficiency. The sedimentation tank is used to treat the mud in the crude oil. The sand settles, and finally the water and salt in the crude oil are removed through the 15KV-25KV high-voltage electric field, which ensures that the crude oil is more pure and improves the quality of the gasoline produced;

[0029]S2: After dehydration in S1, the crude oil is heated to 220℃-250℃ in the initial distillation tower, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com