Carbon nanotube fiber composite shape memory alloy type driver

A carbon nanotube fiber, memory alloy technology, applied in machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., to achieve excellent thermal conductivity and improve the effect of driving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

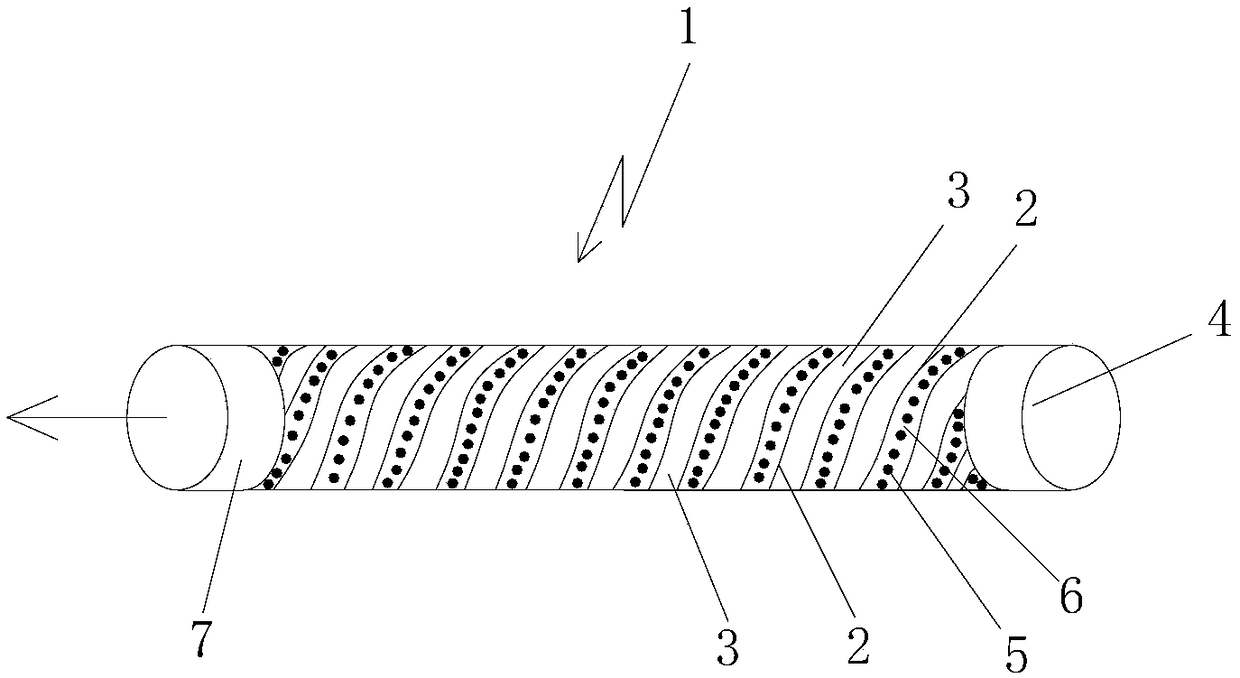

[0025] Carbon nanotube fiber composite shape memory alloy wire laser photothermal driver 1

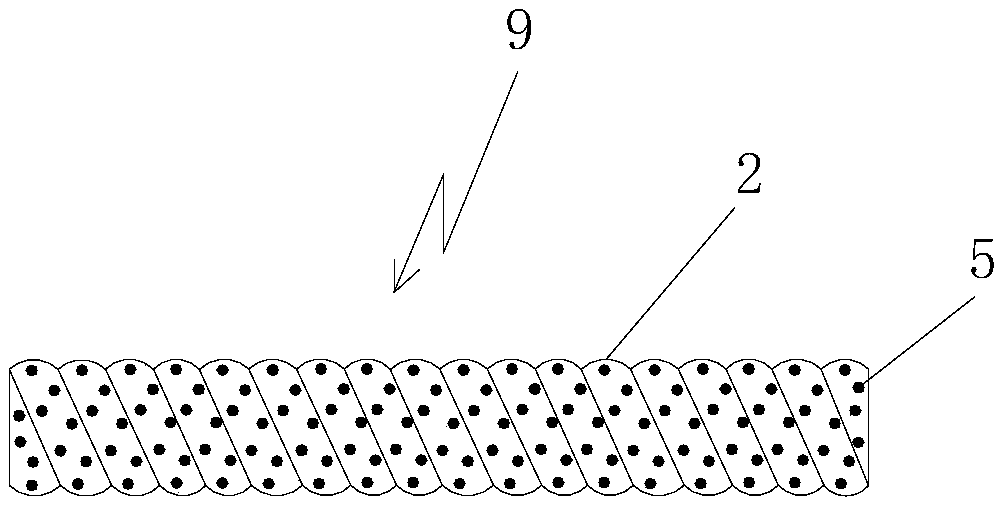

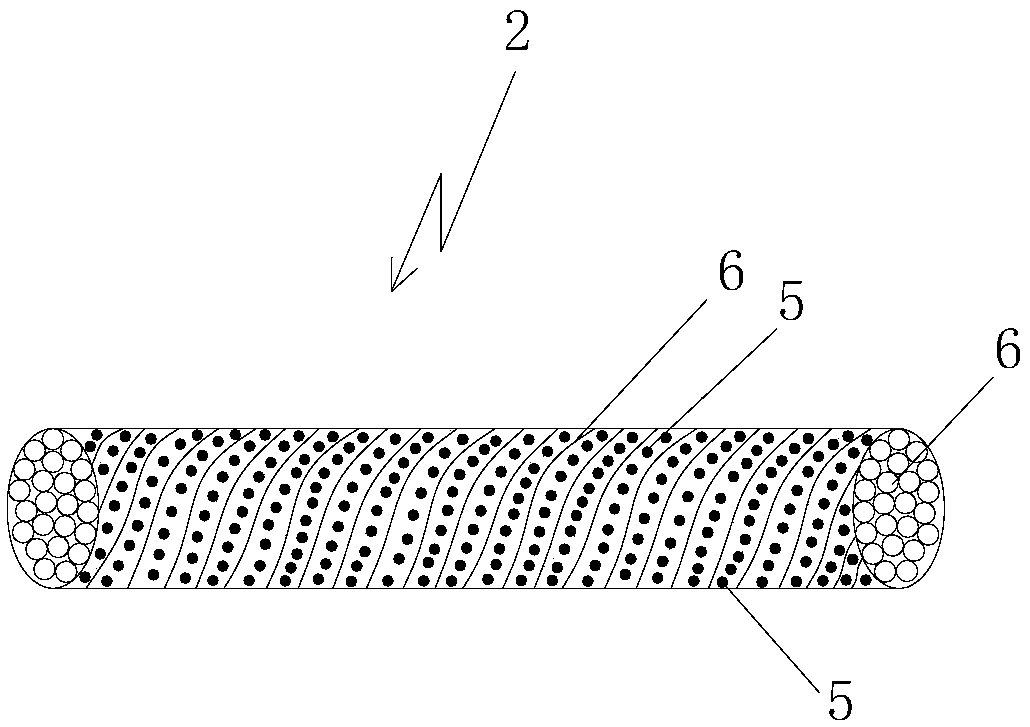

[0026] Schematic diagram of the structure of the carbon nanotube fiber composite shape memory alloy wire type laser photothermal driver 1 in Example 1 of the present invention (see figure 2 ); Nanoparticle composite carbon nanotube fiber yarn structure schematic diagram (see figure 1 ).

[0027] Embodiment 1 of the present invention The specific technical solution for realizing the carbon nanotube fiber composite shape memory alloy wire type laser photothermal driver 1 includes: including: nanoparticle composite carbon nanotube fiber yarn 2, shape memory alloy wire 3, and driver output device 7. The first laser receiver 4, laser; nanoparticle-composite carbon nanotube fiber yarn 2, including: assembling or compounding nanoparticles 5 and carbon nanotube fiber yarn 6; carbon nanotube fiber yarn 6 , including: multiple strand fibers formed by a plurality of single carbon nanotubes or ...

Embodiment 2

[0030] Carbon nanotube fiber composite shape memory alloy cylindrical laser photothermal driver 8

[0031] Schematic diagram of the structure of the carbon nanotube fiber composite shape memory alloy cylindrical laser photothermal driver 8 in Example 2 of the present invention (see image 3 ); Nanoparticle composite carbon nanotube fiber yarn 2 structural representation (see figure 1 ); the first nanoparticle composite carbon nanotube fiber yarn spring layer 9 structural representations (see Figure 4 ).

[0032] Embodiment 2 of the present invention The specific technical solution for realizing the carbon nanotube fiber composite shape memory alloy cylindrical laser photothermal driver 8 includes: the first nanoparticle composite carbon nanotube fiber yarn spring layer 9, the shape memory alloy cylinder 10, the second A nanoparticle composite carbon nanotube fiber yarn helically wound layer 11, a second laser receiver 12, and a laser; the first nanoparticle composite carbon...

Embodiment 3

[0035] Nanoparticle composite carbon nanotube fiber yarn bundle spring type electrothermal driver 13

[0036] The nanoparticle composite carbon nanotube fiber yarn bundle spring type electrothermal driver 13 structure schematic diagram of embodiment 3 of the present invention (see Figure 5 ); the structure of nanoparticle composite carbon nanotube fiber yarn (see figure 1 ); the second nanoparticle composite carbon nanotube fiber yarn spring layer 14 structural representation (see Figure 4 ).

[0037] The nanoparticle-composite carbon nanotube fiber yarn bundle spring-type electrothermal driver 13 according to Example 3 of the present invention includes: a second nanoparticle-composite carbon nanotube fiber yarn spring layer 14, a first shape memory alloy tube layer 15, The second nanoparticle composite carbon nanotube fiber yarn helically wound layer 16; the second nanoparticle composite carbon nanotube fiber yarn spring layer 14 is processed by nanoparticle composite car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com