Technology for restoring heavy-metal polluted seedling-throwing planting rice field by using root system micro geochemical barrier technology

A geochemical and heavy metal technology, applied in the restoration of polluted soil, rice cultivation, land preparation methods, etc., can solve the problems of increasing farmers' labor, high restoration costs, and large material consumption, achieving high applicability and popularization, easy to use. Application promotion, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

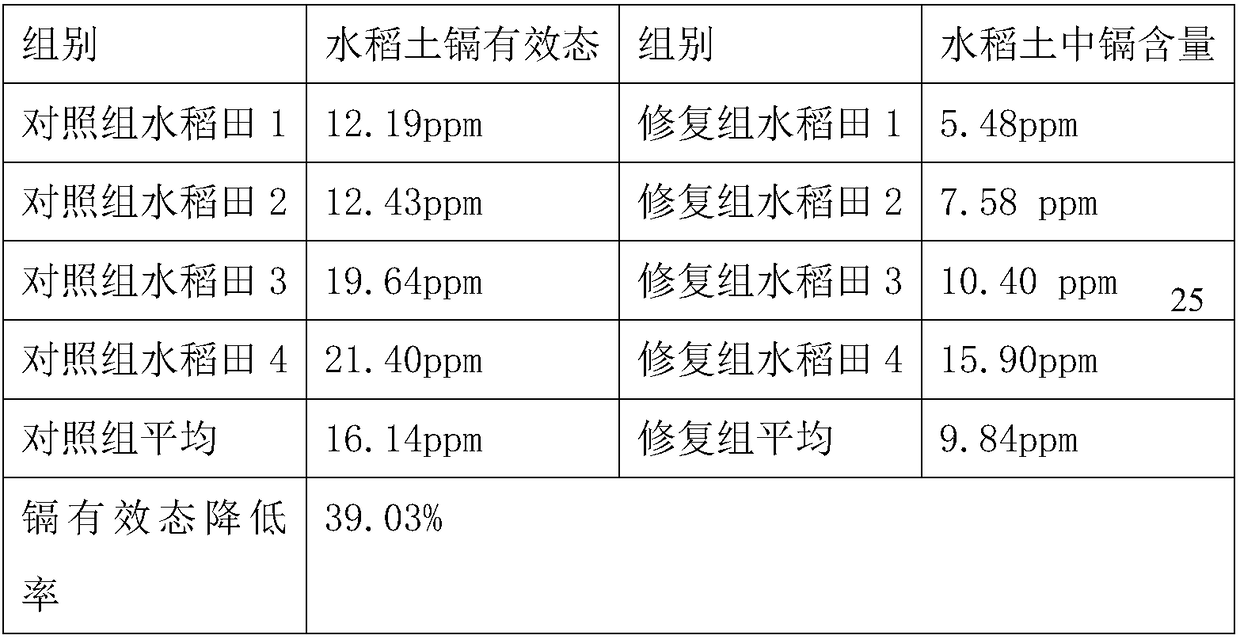

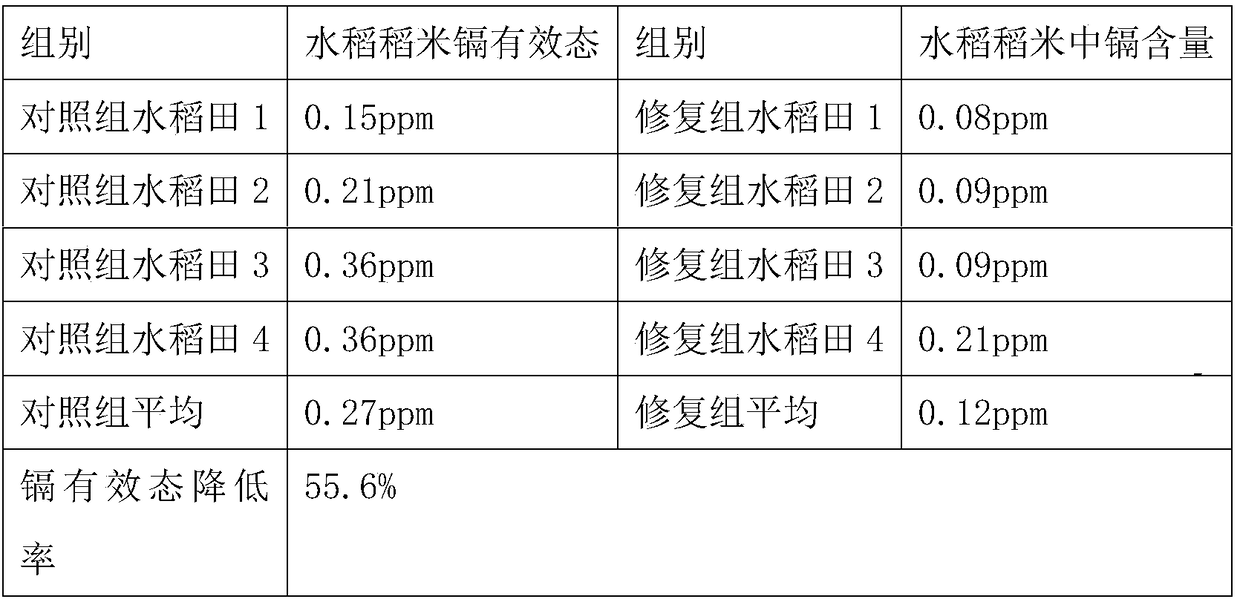

[0036] Rice experimental field 1: Restoration and treatment of paddy fields continuously polluted by cadmium. The paddy soil septum exceeds the standard, and the cadmium in rice exceeds the standard by about one time. Root microgeochemical barrier technology is used to repair heavy metal pollution and throw seedlings to plant paddy fields.

[0037] The heavy metal repair material is prepared according to the following method: grind attapulgite into 200-mesh powder 100g, add 200-mesh aluminum phosphate 3g, 100-mesh pine wood chips 1g, mix evenly, add to the agglomerator, spray and add water to stir, Process into pellets; dry in a blast drying oven at 60-70°C for 6 hours, and then burn in a digital display shuttle kiln at 500°C for about 6 hours.

[0038] Take the seedling soil and sieve it, mix it evenly with the bed soil conditioner and 200 mesh heavy metal repair materials, stack it, and wait for sowing, wherein the weight ratio of seedling soil to heavy metal repair materials...

Embodiment 2

[0040] Rice experimental field 2: Restoration and treatment of paddy fields continuously polluted by cadmium. The paddy soil septum exceeds the standard, and the cadmium in rice exceeds the standard by about one time. Root microgeochemical barrier technology is used to repair heavy metal pollution and throw seedlings to plant paddy fields.

[0041] The heavy metal repair material is prepared according to the following method: grind attapulgite into 100-mesh powder 100g, add 3g of 100-mesh aluminum phosphate, 1g of 100-mesh pine wood chips, mix evenly, add to the agglomerator, spray and add water to stir, Process into pellets; dry in a blast drying oven at 60-70°C for 4 hours, and then burn in a digital display shuttle kiln at 500°C for about 6 hours.

[0042] Take the seedling soil and sieve it, mix it evenly with the bed soil conditioner and 100 mesh heavy metal repair material, stack it, and wait for sowing. The weight ratio of the seedling soil to the heavy metal repair mate...

Embodiment 3

[0044] Rice experimental field 3: Restoration and treatment of paddy fields continuously polluted by cadmium. The paddy soil septum exceeds the standard, and the cadmium in rice exceeds the standard by about one time. Root micro-geochemical barrier technology is used to repair heavy metal pollution and throw seedlings to plant paddy fields.

[0045] The heavy metal repair material is prepared according to the following method: grind attapulgite into 100-mesh powder 100g, add 3g of 100-mesh aluminum phosphate, 1g of 100-mesh pine wood chips, mix evenly, add to the agglomerator, spray and add water to stir, Process into pellets; dry in a blast drying oven at 60-70°C for 6 hours, and then burn in a digital display shuttle kiln at 500°C for about 6 hours.

[0046] Take the seedling soil and sieve it, mix it evenly with the bed soil conditioner and 200 mesh heavy metal repair materials, stack it, and wait for sowing, wherein the weight ratio of seedling soil to heavy metal repair ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com