Production place processing method for improving Chinese yam quality

A production area processing and yam technology, which is applied in the production area processing field for improving the quality of yam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

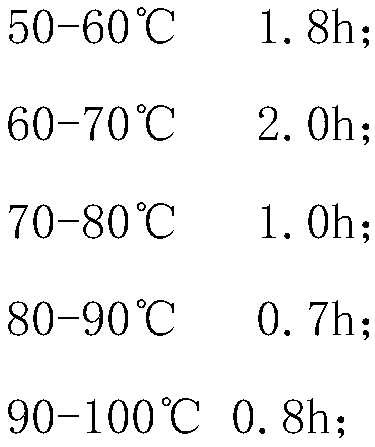

Embodiment 1

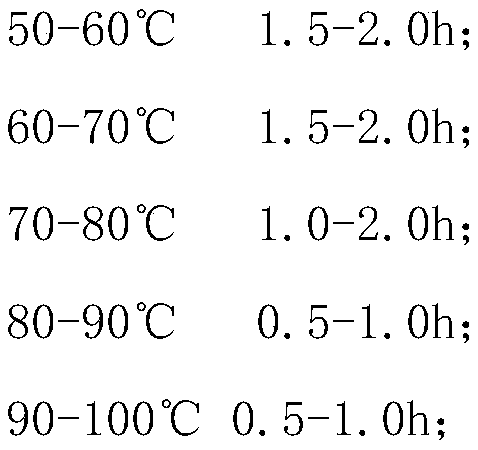

[0042] The local processing method for improving the quality of Chinese yam comprises the following steps:

[0043] S1: Washing and peeling: Take freshly picked yams, wash the soil on the surface with high-pressure spray water, and then scrape off the skin with a blade;

[0044] S2: Anti-oxidation: Cut the yam with the skin removed into thin slices with a thickness of 5mm, soak it in a mixed solution of 4% salt and 5% vinegar for 0.8h, and then soak it in water for 1h. The ratio of salt to vinegar is 1:1;

[0045] S3: Enzyme inactivation: Drain the yam, spread it out, and treat it with microwaves, the microwave frequency is 1000MHz, the power is 110KW, the temperature is 60°C, and the microwave treatment time is 8 minutes;

[0046] S4: color protection; the microwave-treated yam is quickly put into the color protection solution, the amount of the color protection solution is twice that of the yam, rinsed 3 times, 50 minutes each time, the color protection solution is carnosic...

Embodiment 2

[0052] The local processing method for improving the quality of Chinese yam comprises the following steps:

[0053] S1: Washing and peeling: Take freshly picked yams, wash the soil on the surface with high-pressure spray water, and then scrape off the skin with a blade;

[0054] S2: Anti-oxidation: cut the yam with the skin removed into thin slices with a thickness of 4mm, soak it in a mixed solution of 3% salt and 4% vinegar for 0.5h, and then soak it in water for 2h. The ratio of salt to vinegar is 1:5;

[0055] S3: Enzyme inactivation: Drain the yam, spread it out, and treat it with microwaves, the microwave frequency is 900MHz, the power is 100KW, the temperature is 55°C, and the microwave treatment time is 5 minutes;

[0056] S4: color protection; quickly put the microwave-treated yam into the color protection solution, the amount of the color protection solution is 3 times that of the yam, rinse 5 times, 40 minutes each time, the color protection solution is carnosic ac...

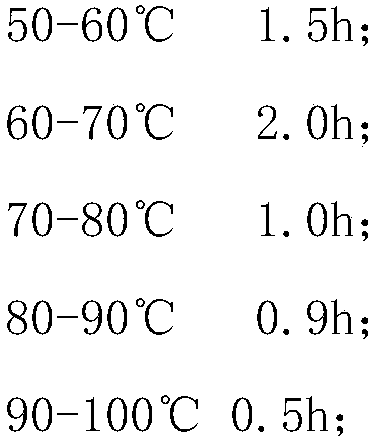

Embodiment 3

[0062] The local processing method for improving the quality of Chinese yam comprises the following steps:

[0063] S1: Washing and peeling: Take freshly picked yams, wash the soil on the surface with high-pressure spray water, and then scrape off the skin with a blade;

[0064] S2: Anti-oxidation: cut the yam with the skin removed into thin slices with a thickness of 6 mm, soak it in a mixed solution of 2% salt and 3% vinegar for 1 hour, and then soak it in water for 1.5 hours. The ratio of salt to vinegar is 2:3;

[0065] S3: Enzyme inactivation: Drain the yam, spread it out, and treat it with microwaves, the microwave frequency is 800MHz, the power is 80KW, the temperature is 50°C, and the microwave treatment time is 10 minutes;

[0066] S4: color protection; the microwave-treated yam is quickly put into the color protection solution, the amount of the color protection solution is twice that of the yam, rinsed 4 times, 30 minutes each time, the color protection solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com