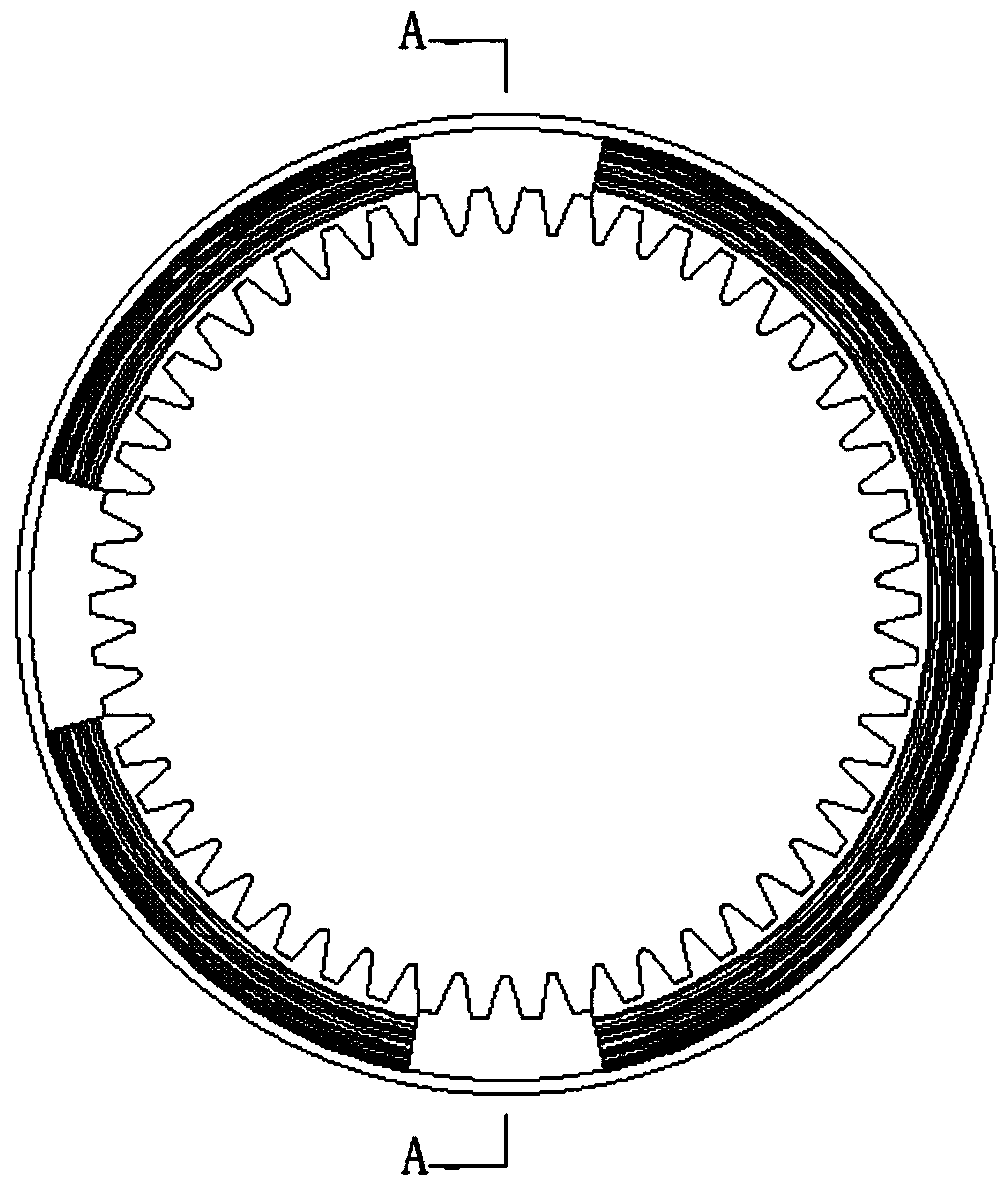

Manufacturing method of adjustable-speed three-jaw inner gear ring

A manufacturing method and technology of internal gears, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of low utilization rate of metal materials, prone to tooth damage, low production efficiency, etc., to improve the strength of teeth and comprehensive mechanical performance, increased ability to transmit torque, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for manufacturing a speed-adjusting three-jaw ring gear includes the following steps:

[0016] Step 1: Proportioning metal powder, weighing 90 parts by weight of iron powder, 2 parts by weight of nickel powder, 1.5 parts by weight of copper powder, 0.5 parts by weight of molybdenum powder and 0.6 parts by weight of sintering aid, the sintering aid The agent includes 0.3 parts by weight of cuprous phosphide powder and 0.3 parts by weight of ferric oxide powder, and the powders weighed are mixed uniformly to form powder metallurgy powder, which is reserved for later use;

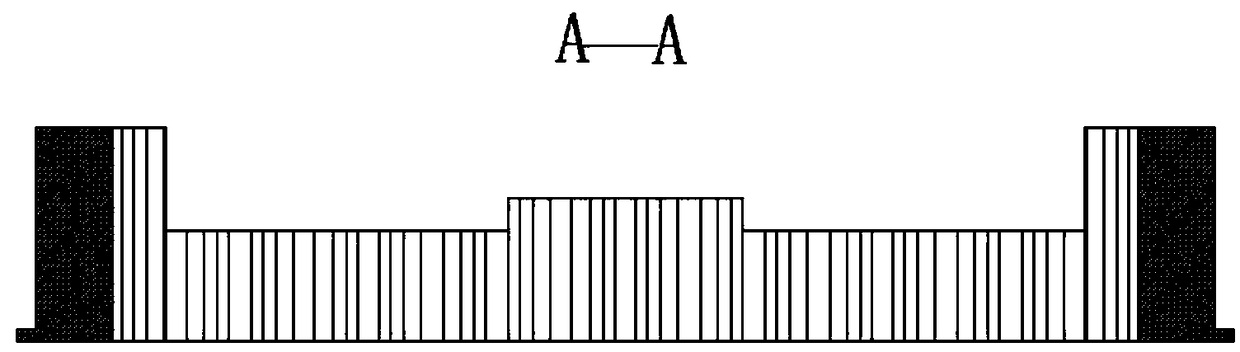

[0017] Step 2: Compression molding, filling the powder metallurgy powder in step 1 into the mold set, the mold set includes a middle mold fixed on the workbench, a lower mold attached to the bottom surface of the middle mold and powder metallurgy The powder is pressed into the upper mold in the space formed by the middle mold and the lower mold. The middle mold includes a horizontally arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com