A laser self-fluxing welding process of aluminum alloy without protective gas

A welding process, aluminum alloy technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of beautiful weld seam, less welding defects, and reduce welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

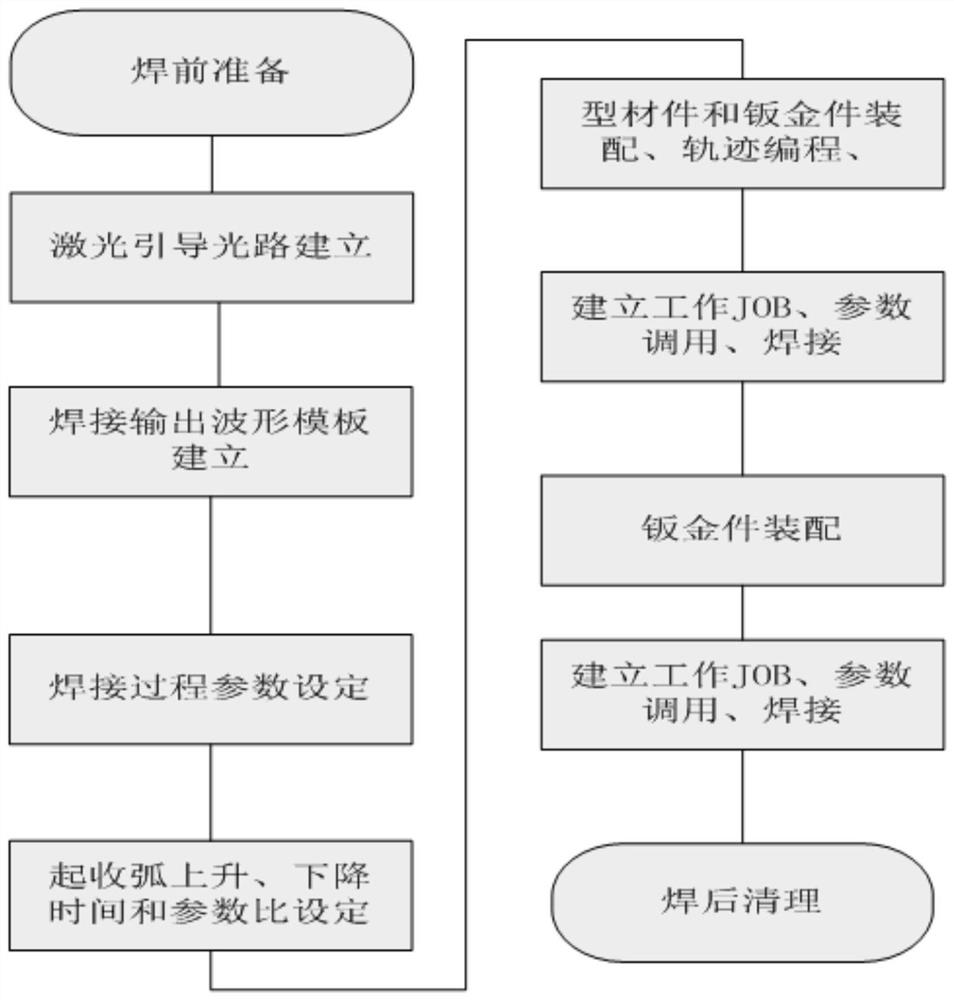

[0036] like figure 1 A laser self-fusion welding process of aluminum alloy without shielding gas shown, mainly includes the welding of profile parts and sheet metal parts and the welding of sheet metal parts and sheet metal parts, wherein the welding process of welding profile parts and sheet metal parts is:

[0037] A. Preparation before welding: Use a wire bowl brush to remove the oxide film on the surface of the profile and sheet metal within a range of 50mm near the weld of the profile and sheet metal to be welded, and then clean the surface of the profile and sheet metal with acetone or ethanol. Oil pollution, in which the profile parts are 2mm thick 6 series aluminum alloys, and the sheet metal parts are 1mm thick 5 series aluminum alloys;

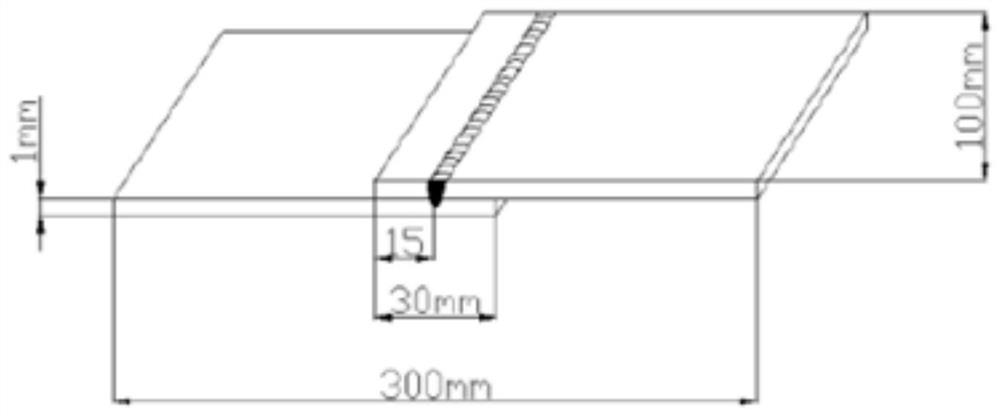

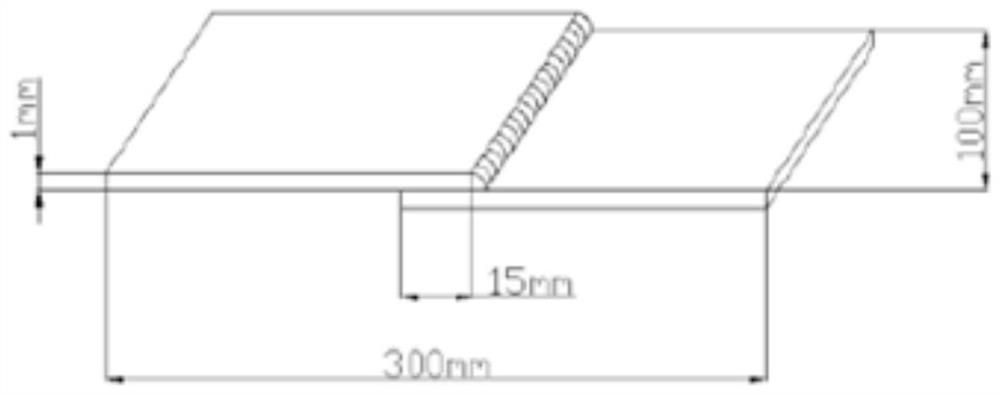

[0038] B. Assembly pair: Use clamping tooling to press the profile parts and sheet metal parts on both sides of the weld to ensure that the weld gap between the profile part and the sheet metal part is 0.2mm. figure 2 For the lap j...

Embodiment 2

[0055] like figure 1 A laser self-fusion welding process of aluminum alloy without shielding gas shown, mainly includes the welding of profile parts and sheet metal parts and the welding of sheet metal parts and sheet metal parts, wherein the welding process of welding profile parts and sheet metal parts is:

[0056] A. Preparation before welding: Use a wire bowl brush to remove the oxide film on the surface of the profile and sheet metal within a range of 25mm near the weld of the profile and sheet metal to be welded, and then clean the surface of the profile and sheet metal with acetone or ethanol. Oil pollution, in which the profile parts are 2mm thick 6 series aluminum alloys, and the sheet metal parts are 1mm thick 5 series aluminum alloys;

[0057] B. Assembly pair: Use clamping tooling to press the profile parts and sheet metal parts on both sides of the weld to ensure that the weld gap between the profile part and the sheet metal part is 0.1mm. figure 2 For the lap j...

Embodiment 3

[0074] like figure 1 A laser self-fusion welding process of aluminum alloy without shielding gas shown, mainly includes the welding of profile parts and sheet metal parts and the welding of sheet metal parts and sheet metal parts, wherein the welding process of welding profile parts and sheet metal parts is:

[0075] A. Preparation before welding: Use a wire bowl brush to remove the oxide film on the surface of the profile and sheet metal within a range of 30mm near the weld of the profile and sheet metal to be welded, and then clean the surface of the profile and sheet metal with acetone or ethanol. Oil pollution, in which the profile parts are 2mm thick 6 series aluminum alloys, and the sheet metal parts are 1mm thick 5 series aluminum alloys;

[0076] B. Assembly pair: Use clamping tooling to press the profile parts and sheet metal parts on both sides of the weld to ensure that the weld gap between the profile part and the sheet metal part is 0.2mm. figure 2 For the lap j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com