Production method of bamboo road protective fence

A production method and guardrail technology, applied in the production field of bamboo highway guardrails, to achieve the effects of realizing cost, improving impregnation effect, and small secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

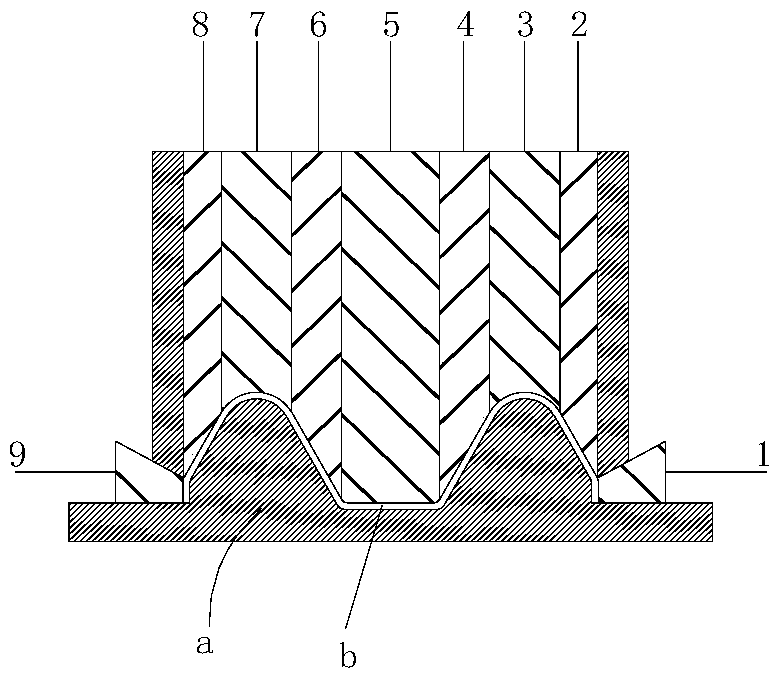

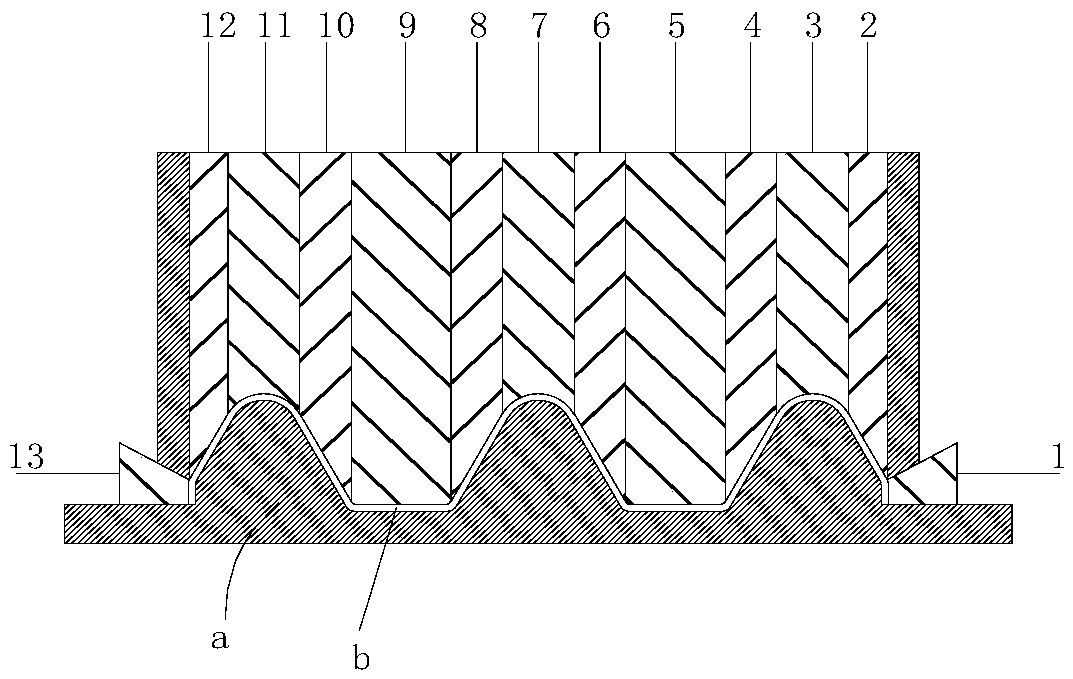

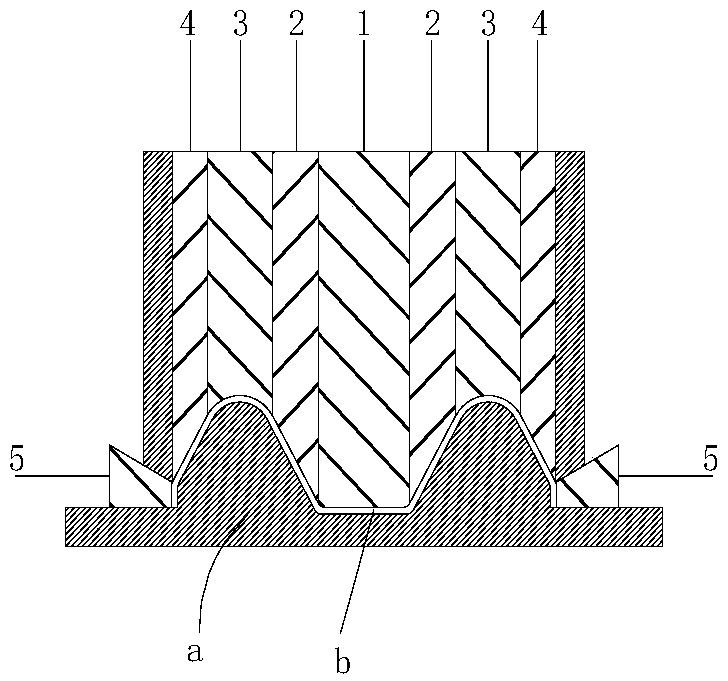

[0026] The present invention will be described in detail below according to the accompanying drawings.

[0027] The present invention is the method for utilizing bamboo material to produce highway guardrail, comprises the following steps:

[0028] Step 1: Slicing the bamboo in the chord direction: Carry out circumferential rotary cutting of the bamboo, or slit the bamboo in the radial direction and then slit it in the chord direction to obtain bamboo slices close to bamboo green, bamboo slices close to bamboo yellow and bamboo flesh , the surface of the near-bamboo-green bamboo slices does not contain bamboo green, and the surface of the near-bamboo-yellow bamboo slices does not contain bamboo yellow. The thickness of the above three kinds of bamboo slices is less than 1.35mm, so as to improve the impregnation effect of the waterproof and weather-resistant glue in the later stage of the bamboo slices and reduce the horizontal Defects caused by the molding and deformation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com