Preparation method of a half-layer thermosetting resin-based composite structure

A technology of composite materials and thermoplastic resins, which is applied in the field of preparation of half-layer thermosetting resin-based composite material structures, and can solve problems such as damage to grinding and perforation, low thickness scale, and damage to grinding and perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

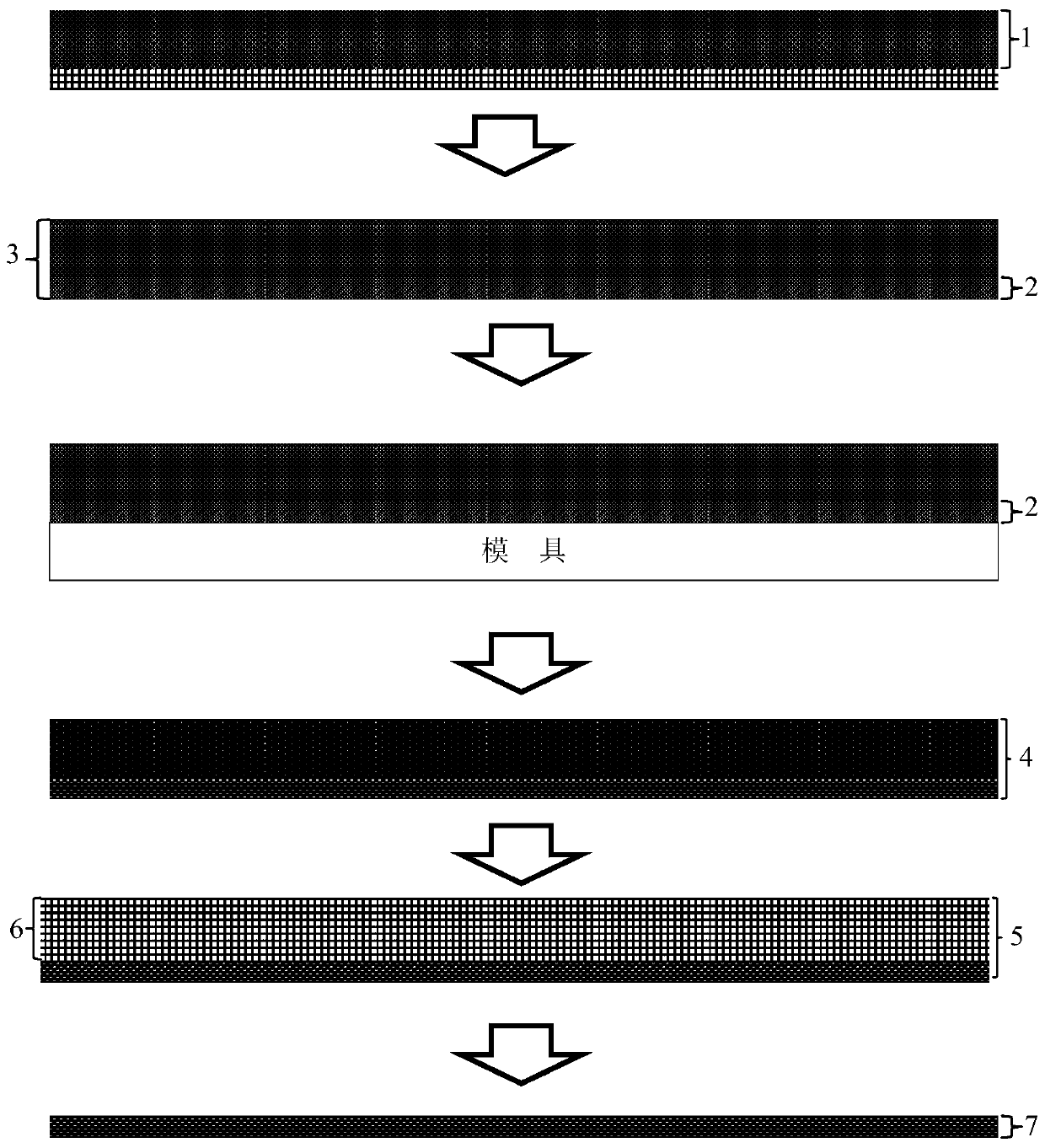

[0018] The preparation method of half-layer thermosetting resin matrix composite structure, see appendix figure 1 ,Specific steps are as follows:

[0019] a. First, use a single-layer fabric as a reinforcement, adopt the method of compounding one side of the single-layer fabric with a thermoplastic resin, and through process control, form a thermoplastic resin prepreg 1 in a part of the thickness of the single-layer fabric. Single-layer The material of the fabric is glass fiber or carbon fiber, the structural form is one or more of plain weave, twill weave or satin weave, and the thermoplastic resin is polyaryletherketone, which may include polyetheretherketone or polyaryletherketone One or more of ether sulfones.

[0020] b. Then, compound the other side of the single-layer fabric with thermoplastic resin prepreg in the above-mentioned part of the thickness area, and compound it with thermosetting resin. Thermosetting resin refers to double horse resin, epoxy resin, cyanate ...

Embodiment

[0025] Preparation of half-layer EW100A / epoxy resin matrix composite structure

[0026] a. First, use the single-layer glass fiber plain weave fabric EW100A (single-layer thickness 0.1mm) as a reinforcement, and adopt the method of compounding one side of the single-layer EW100A fabric with thermoplastic polyaryletherketone resin, through process control, in a single layer A thermoplastic polyaryletherketone resin prepreg is formed in the area of 1 / 3 nominal thickness of the layer EW100A fabric;

[0027] b. Then, still using single-sided composite method, through process control, epoxy resin prepreg is formed in the 2 / 3 nominal thickness area of single-layer EW100A fabric that is not composited with thermoplastic polyaryletherketone resin, and thermoplastic polyaryletherketone resin is obtained. Aryl ether ketone resin / epoxy resin laminated prepreg;

[0028] c. Secondly, the above-mentioned thermoplastic polyaryletherketone resin / epoxy resin laminated prepreg is used, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com