Production process of high-coverage synthetic paper

A production process and technology for synthetic paper, applied in paper/cardboard layered products, papermaking, paper coatings, etc., can solve the problems of poor printing performance, bending resistance and bonding strength, and poor covering performance, so as to improve covering performance, Guaranteed appearance and good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

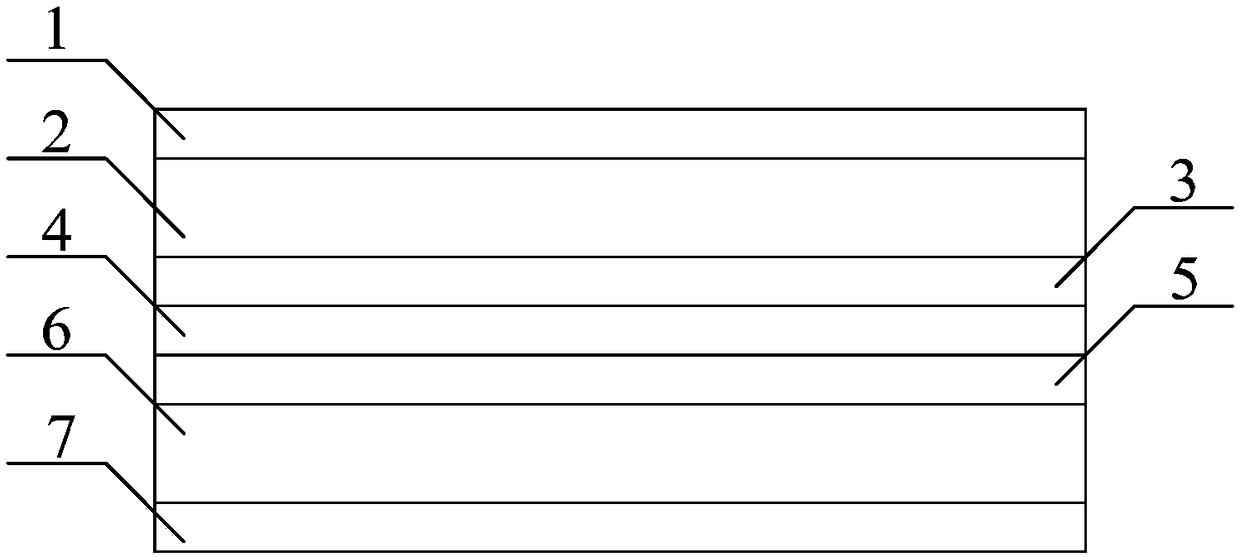

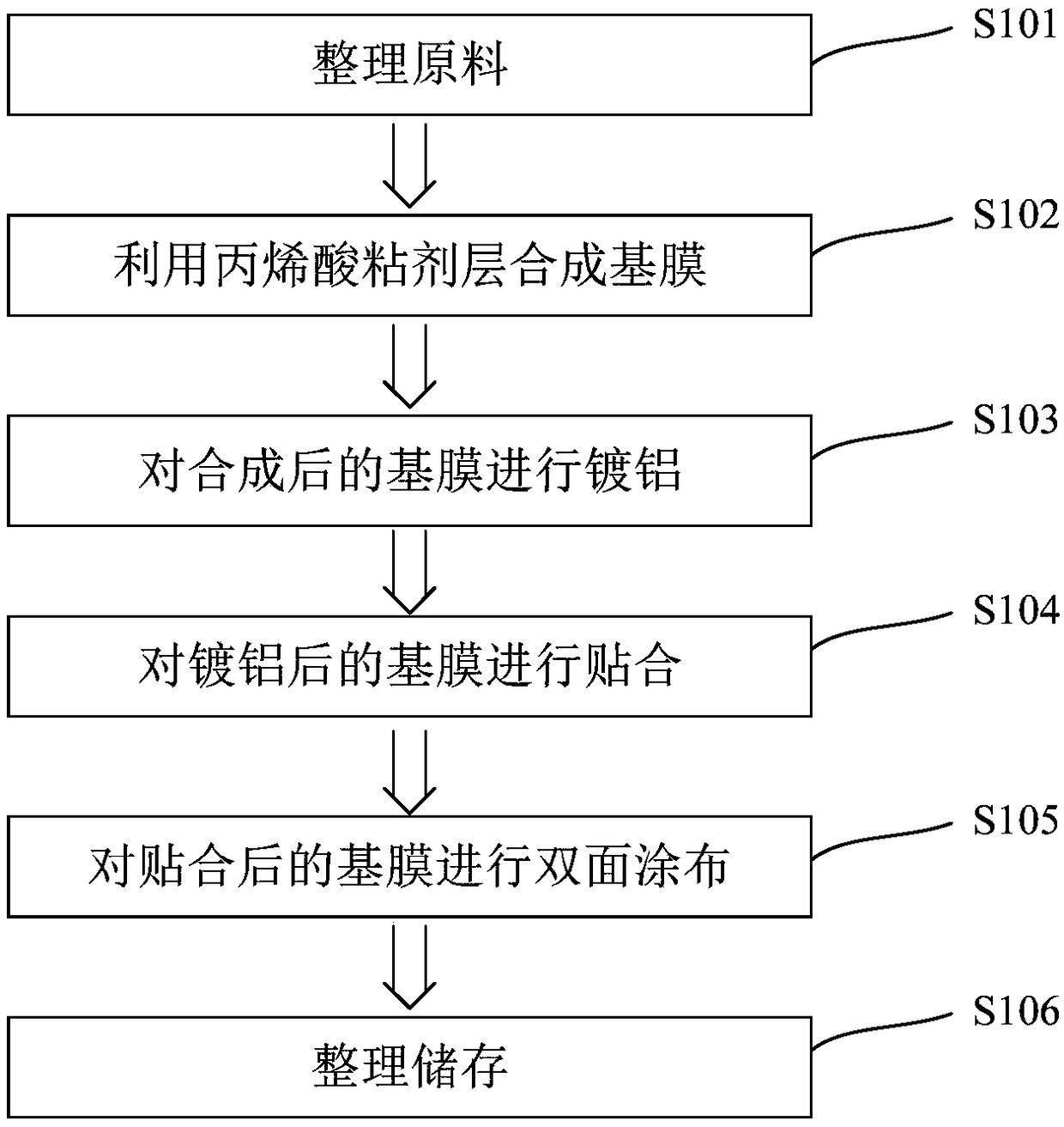

[0058] Embodiment 1: First select synthetic paper coating, biaxially stretched pearlescent synthetic paper layer, aluminum-plated layer and acrylic composite adhesive layer as raw materials, then acrylic adhesive is put into high-speed mixer and stirred, and the acrylic adhesive after stirring is sent to Put it into the calender for calendering, and the calendered billet will be further plasticized and calendered into a base film layer with a thickness of 0.04mm to 0.055mm after continuous calendering, and then put the synthesized base film into the aluminum coating machine Aluminum-plate the front and back of the inner pair, and keep the thickness of the aluminum-coated layer at 0.02mm to 0.035mm, and then use pearlescent synthetic paper with a thickness of 0.04mm to 0.05mm to bond the aluminum-plated base film layer in vacuum Laminating in the machine, putting the laminated base film into the coating machine for double-sided coating to obtain the finished synthetic paper; fin...

Embodiment 2

[0059] Embodiment 2: First select synthetic paper coating, biaxially stretched pearlescent synthetic paper layer, aluminum-plated layer and acrylic composite adhesive layer as raw materials, then acrylic adhesive is put into high-speed mixer and stirred, and the acrylic adhesive after stirring is sent to Put it into a calender for calendering, and the calendered billet will be further masticated and calendered into a base film layer with a thickness of 0.04mm to 0.05mm after continuous calendering. Put the synthesized base film into the aluminum coating machine Aluminum-plate the front and back of the inner pair, and keep the thickness of the aluminum-coated layer at 0.03mm to 0.035mm, and then use pearlescent synthetic paper with a thickness of 0.045mm to 0.05mm to bond the aluminum-plated base film layer in vacuum Carry out bonding in the machine, put the bonded base film into the coating machine for double-sided coating to obtain the finished synthetic paper; finally, wind t...

Embodiment 3

[0060] Embodiment 3; First select synthetic paper coating, biaxially stretched pearlescent synthetic paper layer, aluminum-plated layer and acrylic composite adhesive layer as raw materials, then acrylic adhesive is put into high-speed mixer and stirred, and the acrylic adhesive is sent to Put it into the calender for calendering, and the calendered billet will be further masticated and calendered into a base film layer with a thickness of 0.045mm to 0.05mm after continuous calendering. Put the synthesized base film into the aluminum coating machine Aluminum-plate the front and back of the inner pair, and keep the thickness of the aluminum-coated layer at 0.03mm to 0.033mm, and then use pearlescent synthetic paper with a thickness of 0.04mm to 0.045mm to bond the aluminum-plated base film layer in vacuum Carry out bonding in the machine, put the bonded base film into the coating machine for double-sided coating to obtain the finished synthetic paper; finally, wind the finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com