Preparation method and application of biomass-based activated carbon with porous channel and hierarchical pore structure

A technology based on activated carbon and biomass carbon, which is applied in chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, carbon compounds, etc. The effect of excellent rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

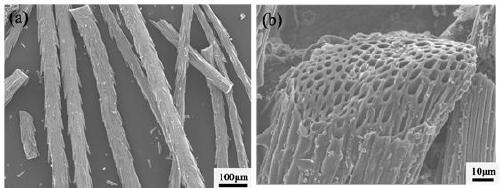

[0036] (1) Weigh 10 g of foxtail, wash 3 times with acetone solution, each time the amount of acetone solution is 10 ml / g (i.e. 100 ml), then wash 4 times with deionized water, each time the amount of deionized water solution is 20 ml / g (ie 200 ml), then at 80 o Dry at C for 5 h to obtain a clean precursor material;

[0037] (2) Mix the foxtail precursor material in step (1) at 400 o C, N 2 Pre-carbonize in the atmosphere environment for 2 h, the gas flow rate is 2 ml min -1 g -1 , to obtain biomass carbonized samples;

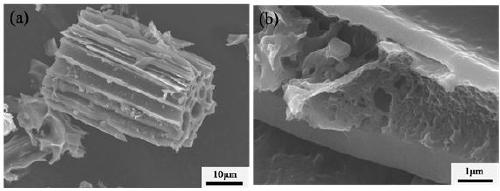

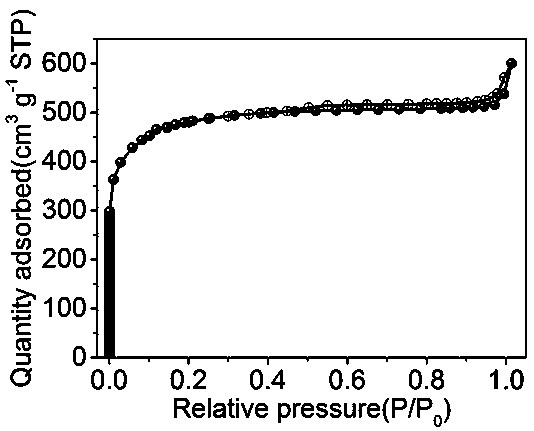

[0038] (3) Weigh 2 g of the biomass carbonized sample in step (2), mix it with 2 g of KOH particles (mass ratio 1:1), and use 40 ml (1:10 g / ml) of deionized water to make The two are fully mixed, at 80 o C dried for 12 h, and then the resulting mixture was placed in a tubular carbonization furnace, N 2 atmosphere at 800 o C heat treatment for 2 h, naturally cooled to room temperature, the mixture was first washed 3 times with deionized water, then wa...

Embodiment 2

[0050] (1) Weigh 15 g of foxtail, wash 4 times with acetone solution, each time the amount of acetone solution is 180 ml (ie 12 ml / g), then wash with deionized water 3 times, each time the amount of deionized water solution is 375 ml (ie 25 ml / g), and then at 90 o Dry at C for 4 h to obtain a clean precursor material;

[0051] (2) Put the foxtail precursor material in step (1) at 450 o C, N 2 Pre-carbonize in the atmosphere environment for 1 h, the gas flow rate is 4 ml min -1 g -1 , to obtain biomass carbonized samples;

[0052] (3) Weigh 3 g of the biomass carbonized sample in step (2), mix it with 6 g of KOH particles (mass ratio 1:2), and use 108 ml (1:12 g / ml) of deionized water to make The two are fully mixed, at 90 o C for 11 h, and then the resulting mixture was placed in a tubular carbonization furnace, N 2 Atmosphere below 600 o C heat treatment for 3 h, naturally cooled to room temperature, the mixture was first washed 4 times with deionized water, then was...

Embodiment 3

[0055] (1) Weigh 20 g of foxtail, wash 5 times with acetone solution, each time the amount of acetone solution is 300 ml (ie 15 ml / g), and then wash 5 times with deionized water, each time the amount of deionized water solution is 600 ml (ie 30 ml / g), then at 100 o Dry at C for 3 h to obtain a clean precursor material;

[0056] (2) Mix the foxtail precursor material in step (1) at 500 o Pre-carbonization at C for 3 h in an Ar atmosphere with a gas flow rate of 6 ml min -1 g -1 , to obtain biomass carbonized samples;

[0057] (3) Weigh 4 g of the biomass carbonized sample in step (2), mix it with 12 g of KOH particles (mass ratio 1:3), and use 240 ml (1:15 g / ml) of deionized water to make The two are mixed thoroughly, at 100 o C dried for 10 h, and then the resulting mixture was placed in a tubular carbonization furnace, N 2 atmosphere below 700 o C heat treatment for 2.5 h, naturally cooled to room temperature, the mixture was first washed 5 times with deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com