Treatment device for phenolic resin production wastewater

A technology for the production of waste water and treatment devices, which is applied in the direction of biological treatment devices, biological water/sewage treatment, water/sewage treatment, etc., to achieve the effect of realizing sewage resources, less infrastructure investment, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

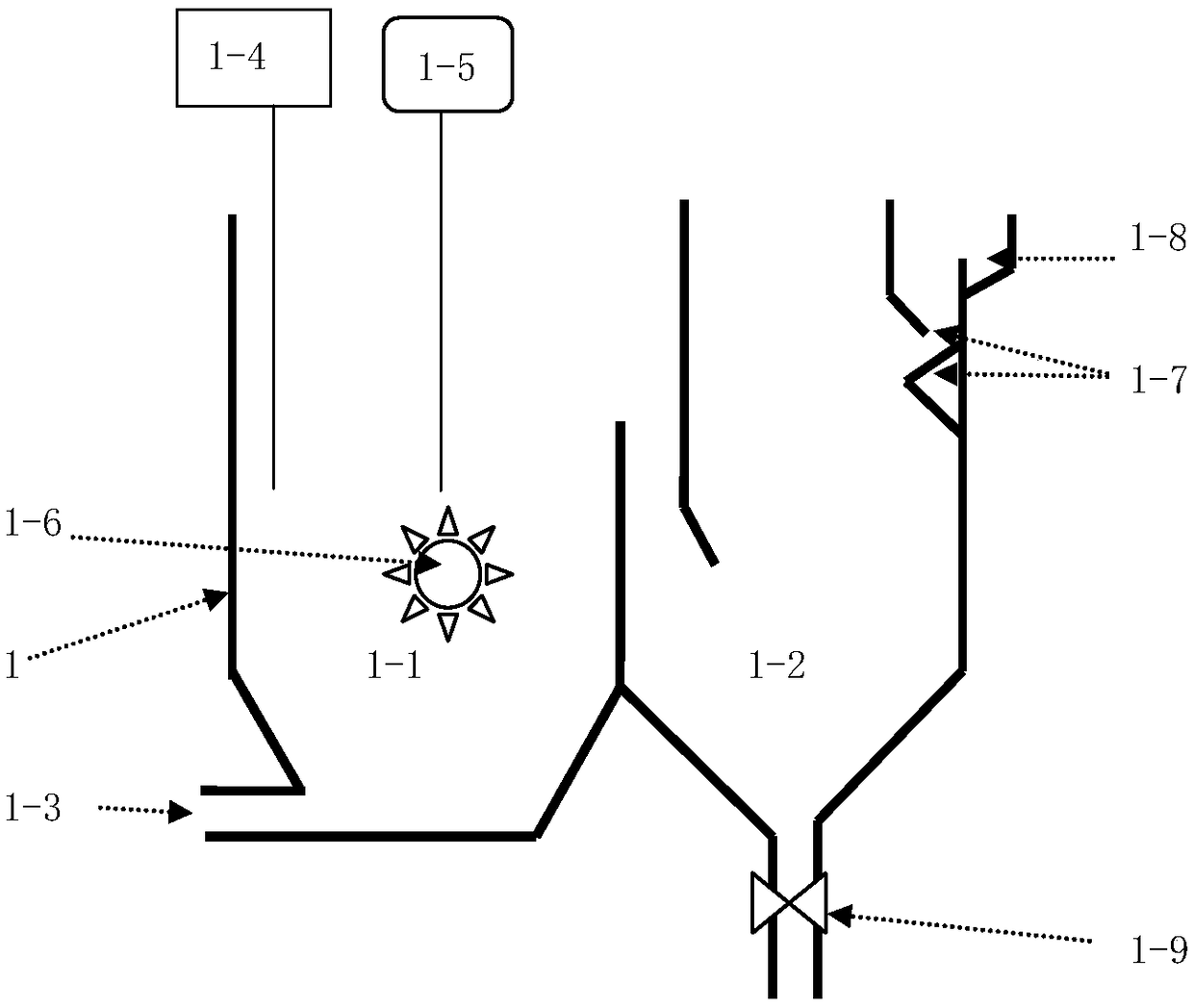

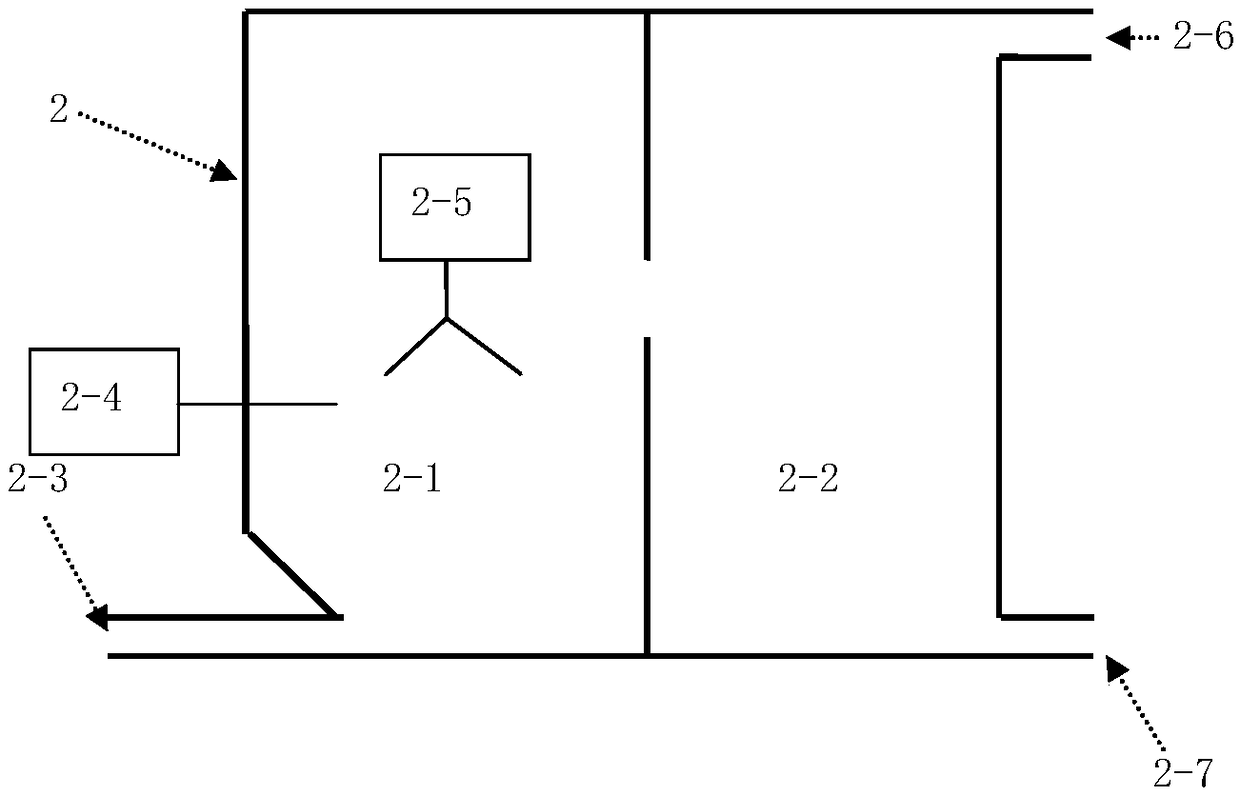

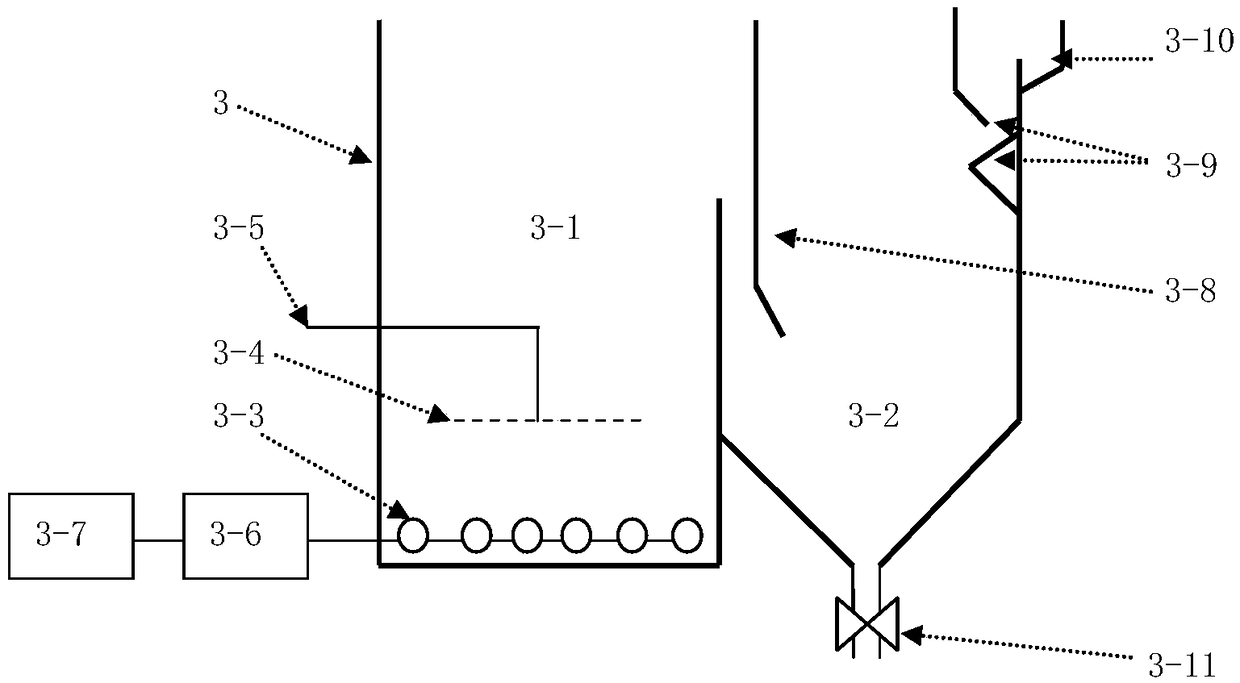

[0042] Such as Figure 1 to Figure 7 Shown, a kind of phenolic resin production waste water treatment device of the present invention comprises regulating tank, catalytic condensation tank 1, extraction tank 2, neutralization tank, advanced oxidation tank 3, anaerobic tank 4, aerobic tank 5, quicksand filter tank 6 and clear water pool; regulating pool, catalytic condensation pool 1, extraction pool 2, neutralization pool, advanced oxidation pool 3, anaerobic pool 4, aerobic pool 5, quicksand filter pool 6 and clear water pool are connected in sequence.

[0043] The regulating pond includes a regulating pond inlet pipe and a regulating pond outlet pipe for regulating the water quality and quantity of the waste water.

[0044] The catalytic condensation tank 1 includes a mixing and stirring zone 1-1 and a solid accumulation zone 1-2, the bottom of the mixing and stirring zone is provided with a catalytic condensation tank inlet pipe 1-3, and the upper part of the mixing and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com