Wear-resisting dry particles of soft brick with waxy luster texture and soft retro ceramic brick

A dry grain and texture technology, applied in the field of ceramic building materials, can solve the problems of poor practical effect and difficult to meet the requirements of wear resistance, and achieve the effect of smooth and delicate touch, bright color and strong color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

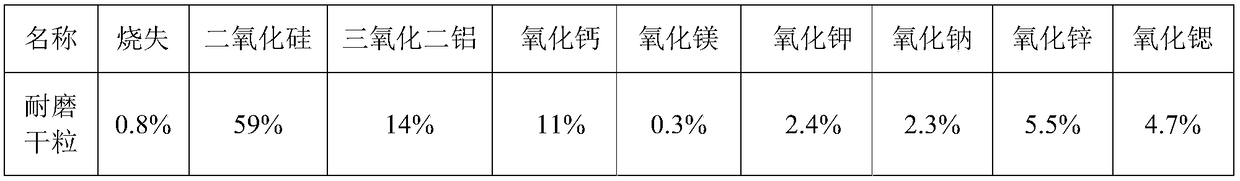

[0018] The invention claims to protect a kind of wear-resistant dry grain of soft surface antique brick with waxy texture. The proportion of the wear-resistant dry particles is as follows according to the weight percentage: the proportion of the wear-resistant dry particles is as follows: silicon dioxide: 51.06-59wt%, aluminum oxide: 10-20wt%, calcium oxide: 7-12wt% , magnesium oxide: 0.2~1.4wt%, potassium oxide: 1~5.1wt%, sodium oxide: 0.5~5.5wt%, zinc oxide: 1~6wt%, strontium oxide: 3~5.2wt%, wherein, the three The ratio of aluminum oxide to silicon dioxide is between 1:5 and 2:5. The wear-resistant dry particles can be processed into a fineness of 80-100 or 140-160. The wear-resistant dry particles are in the glaze In use, the addition amount is preferably 9-11.

[0019] Further, the wear-resistant dry particles are prepared from frit raw material and raw meal by the following method, the frit raw material is heated to make it reach a molten state; performing microcrystal...

Embodiment 2

[0025] The invention claims to protect a kind of wear-resistant dry grain of soft surface antique brick with waxy texture. The proportion of the wear-resistant dry particles is as follows according to the weight percentage: the proportion of the wear-resistant dry particles is as follows: silicon dioxide: 55wt%, aluminum oxide: 11wt%, calcium oxide: 7-12wt%, magnesium oxide: 0.2-1.4wt%, potassium oxide: 1-5.1wt%, sodium oxide: 0.5-5.5wt%, zinc oxide: 1-6wt%, strontium oxide: 3-5.2wt%, wherein the aluminum oxide and The ratio of silicon dioxide is 1:5, and the wear-resistant dry granule can be processed into a fineness of 80-100, and the addition amount of the wear-resistant dry granule is preferably 9-11 in the use of glaze.

[0026] Further, the wear-resistant dry particles are prepared from frit raw material and raw meal by the following method, the frit raw material is heated to make it reach a molten state; performing microcrystallization treatment on the block raw materi...

Embodiment 3

[0028] The invention claims to protect a kind of wear-resistant dry grain of soft surface antique brick with waxy texture. The wear-resistant dry particles are proportioned as follows according to weight percentage: silicon dioxide: 52wt%, aluminum oxide: 20.8wt%, calcium oxide: 7-12wt%, magnesium oxide: 0.2-1.4wt%, potassium oxide: 1- 5.1wt%, sodium oxide: 0.5-5.5wt%, zinc oxide: 1-6wt%, strontium oxide: 3-5.2wt%, wherein, the ratio of aluminum oxide to silicon dioxide is 2:5, and the The wear-resistant dry granules can be processed to a fineness of 80-100, and the addition amount of the wear-resistant dry granules is preferably 9-11 in the use of glaze.

[0029] Further, the wear-resistant dry particles are prepared from frit raw material and raw meal by the following method, the frit raw material is heated to make it reach a molten state; performing microcrystallization treatment on the block raw material; performing water quenching treatment on the microcrystallized frit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com