A low gloss black polyimide film comprising a stress canceling resin layer and a method for producing the same

A black polyimide, polyimide resin technology, applied in synthetic resin layered products, chemical instruments and methods, coatings, etc., can solve the problem of low gloss, low gloss, difficult to produce thin films, and difficult to protect circuit cover films Matching process and other issues, to achieve the effect of excellent flatness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

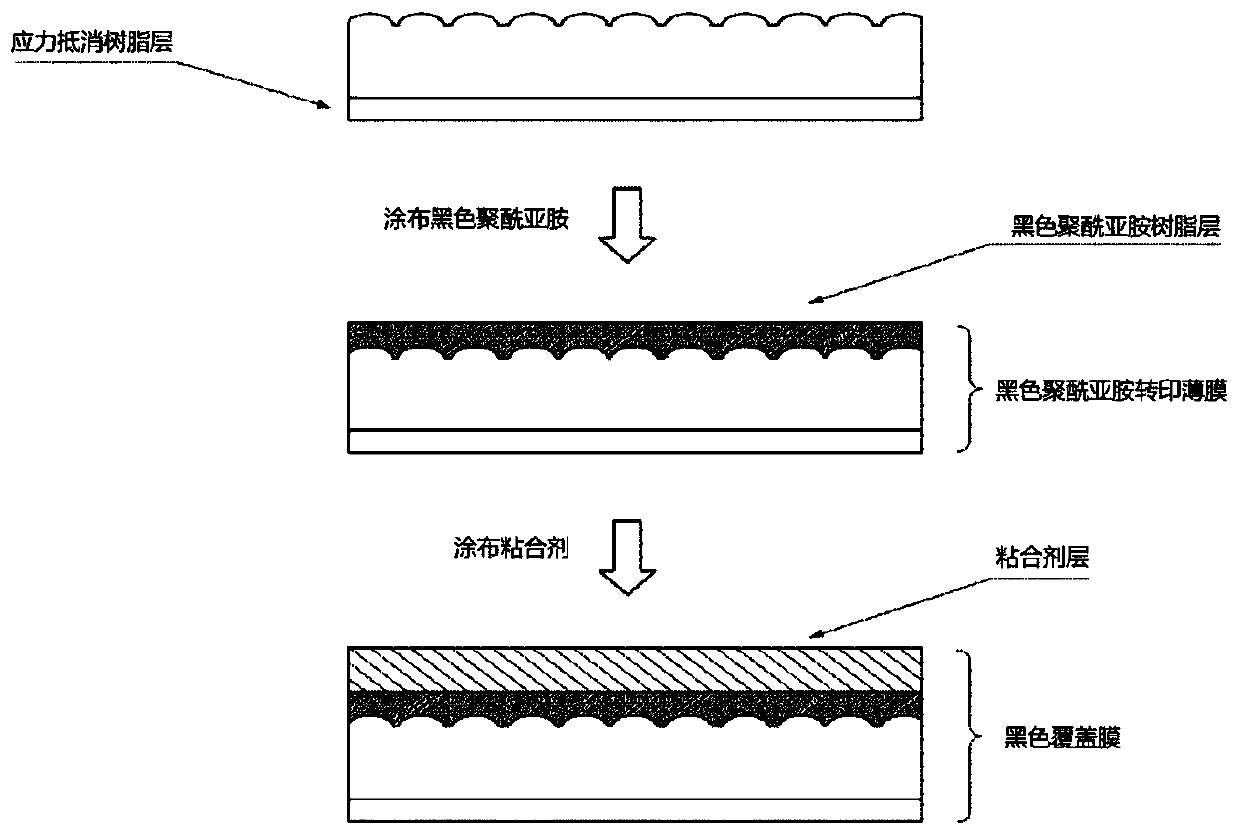

[0056] The preparation method of the existing black polyimide film related to an embodiment of the present invention adopts the solution casting method (Solution Casting), which includes the following steps: polyamic acid solution is polymerized by dianhydride and diamines; The polyamic acid solution and carbon black, such as silicon dioxide, TiO 2 The matting agent, acid anhydrides and tertiary amines used for imidization are mixed as a catalyst to form a film. At this time, the polyamic acid solution and the mixed catalyst are coated (casting, Casting) on the support (endless belt), and after drying in the specified temperature range, the self-supporting gel film in a semi-dry state Peeled from the endless belt and transferred to a high temperature drying oven to go through the amidation process to provide a low gloss black polyimide film.

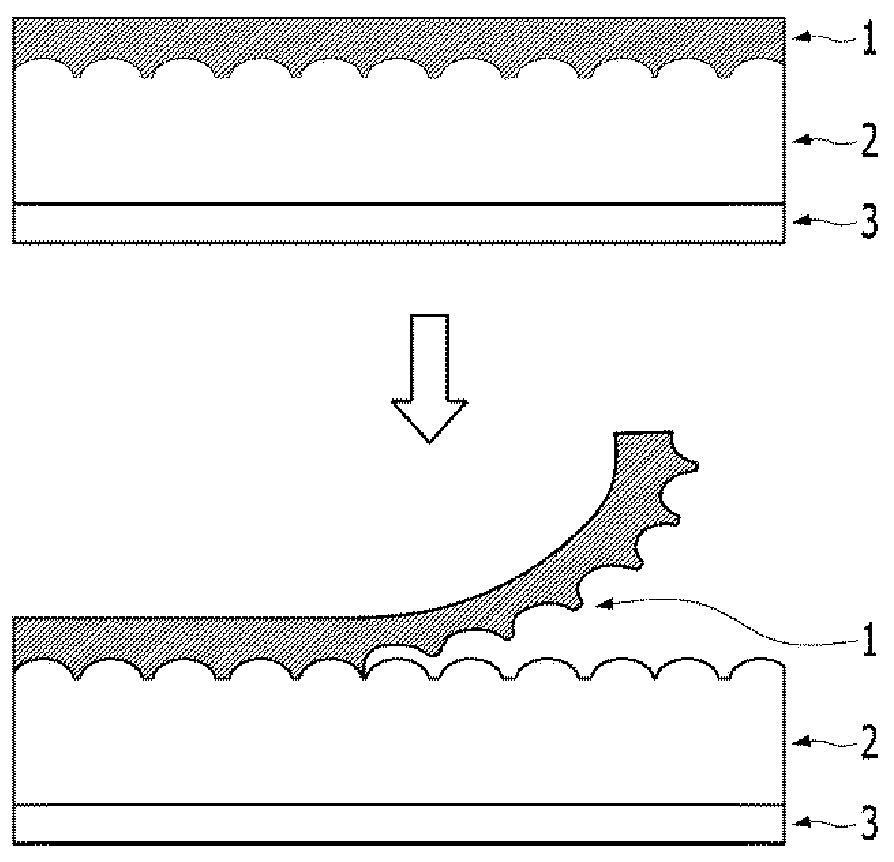

[0057] However, due to the large difference in specific gravity between the matting particles and polyimide in this composition, pre...

Embodiment 1

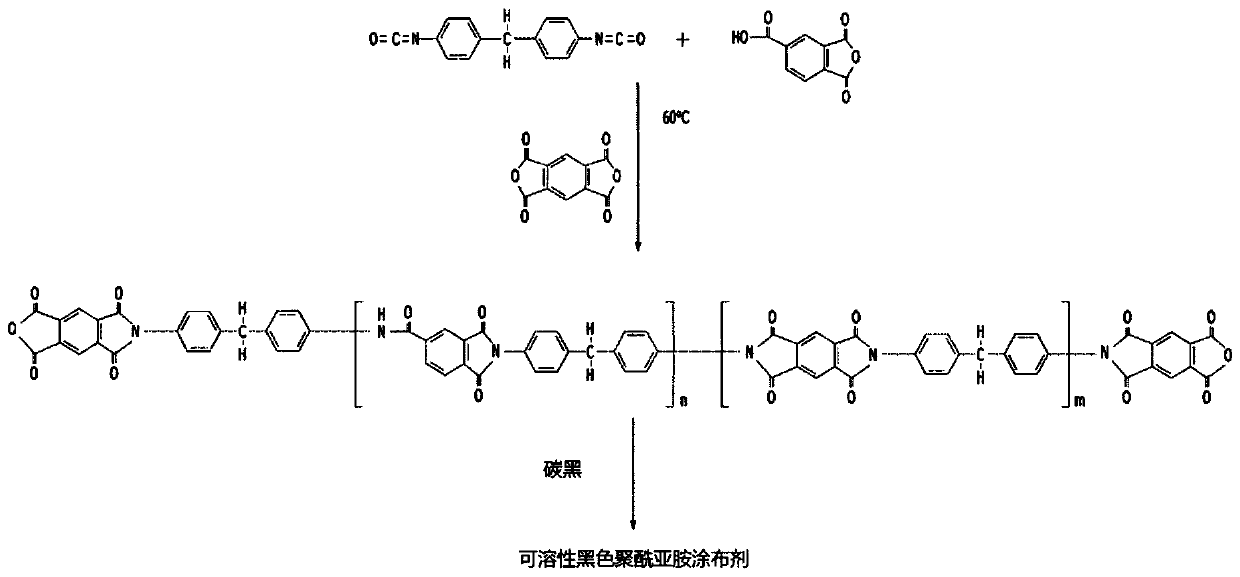

[0082] As a soluble polyimide solution polymerization process, after filling a 1-liter reactor with nitrogen, 51.428 g (0.268 mol) of trimellitic anhydride and 200 g of N-methyl-2-pyrrolidone were added to the reactor. Afterwards, while the reactor was stirred at a rotating speed of about 200 RPM, 79.448 g (0.3029 mol) of 4,4'-methylene diphenyl diisocyanate was dissolved in 200 g of N-methyl-2-pyrrolidone for a period of 1 hour, slowly added to the reactor, and further stirred at 200 RPM for about 30 minutes. After the solution was slowly heated to 80°C over 30 minutes, and stirred for another 30 minutes, 10.303g (0.047mol) of pyromellitic anhydride and 125g of N-methyl-2-pyrrolidone were added in sequence , and stirred for 30 minutes, then over a period of about 30 minutes, the temperature was raised to 140° C. again. Afterwards, while keeping the temperature of the solution at 140°C, rotate and stir at a speed of 100RPM for about 30 minutes, slowly cool the solution that h...

Embodiment 2

[0087] A black polyimide film was prepared in the same manner as in Example 1, except that the thickness of the stress-relieving resin layer in the support film was 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com