Surface-modification method for hexagonal boron nitride

A technology of hexagonal boron nitride and surface modification, used in organic chemistry, preparation of amino compounds from amines, etc., can solve problems such as harsh modification conditions, low grafting rate, and insignificant improvement in neutron absorption performance, achieving The effect of improving the dispersibility and improving the interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

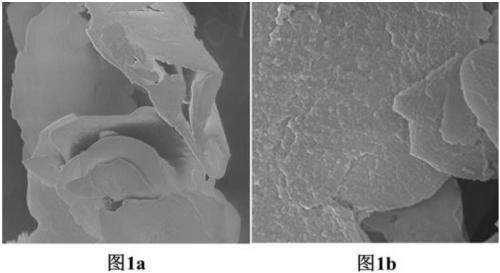

[0061] (1) Weigh 2.8g of sodium hydroxide and 2.2g of potassium hydroxide, add 1g of hexagonal boron nitride nanosheets, grind them into fine powder in a mortar, and mix well. The mixed powder was reacted in a crucible at 180° C. for 3 h, and cooled to room temperature. The mixed powder treated by the solid phase method was dispersed in a certain amount of water, the mixed solution was treated with an ultrasonic cell pulverizer for 2 hours, and then the supernatant was removed by centrifugation. Washing with distilled water 3 times until the pH of the solution is neutral to obtain pre-hydroxylated hexagonal boron nitride.

[0062] (2) In an ice bath, dissolve 5.4 g of p-phenylenediamine in 4 mL of 98% concentrated sulfuric acid and 32 mL of deionized water, and stir until the p-phenylenediamine is completely dissolved. Add 30% sodium nitrite solution dropwise from the liquid surface to the above solution to prepare the corresponding sulfated diazonium salt solution.

[0063]...

Embodiment 2

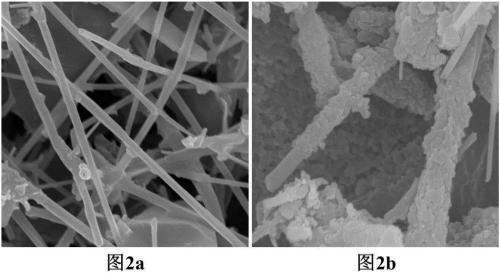

[0065] (1) Weigh 2.8g of sodium hydroxide and 2.2g of potassium hydroxide, add 1g of hexagonal boron nitride nanosheets, grind them into fine powder in a mortar, and mix well. Transfer the mixed powder into a 100mL hydrothermal reaction kettle, add 70mL of pure water, react at 180°C for 6h, cool to room temperature, use an ultrasonic cell pulverizer to treat the mixture for 2h, and then centrifuge to remove the supernatant, the lower layer Washing with distilled water for 3 times until the pH of the solution is neutral to obtain pre-hydroxylated hexagonal boron nitride.

[0066] (2) In an ice bath, dissolve 5.4 g of p-phenylenediamine in 4 mL of 98% concentrated sulfuric acid and 32 mL of deionized water, and stir until the p-phenylenediamine is completely dissolved. Add 30% sodium nitrite solution dropwise from the liquid surface to the above solution to prepare the corresponding sulfated diazonium salt solution.

[0067] (3) Disperse the pre-hydroxylated hexagonal boron nit...

Embodiment 3

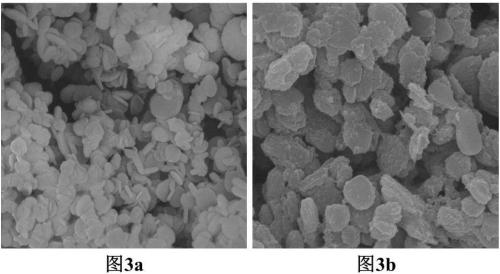

[0069] (1) Weigh 2.8g of sodium hydroxide and 2.2g of potassium hydroxide, add 1g of hexagonal boron nitride nanosheets, grind them into fine powder in a mortar, and mix well. First react the mixed powder in a crucible at 180°C for 3h, then transfer the mixed powder into a 100mL hydrothermal reaction kettle, add 70mL of pure water, and react at 180°C for 6h. After cooling to room temperature, the mixture was treated with an ultrasonic cell disruptor for 2 hours, and then the supernatant was removed by centrifugation, and the lower layer was washed with distilled water three times until the pH of the solution was neutral to obtain pre-hydroxylated hexagonal boron nitride.

[0070] (2) In an ice bath, dissolve 5.4 g of p-phenylenediamine in 4 mL of 98% concentrated sulfuric acid and 32 mL of deionized water, and stir until the p-phenylenediamine is completely dissolved. Add 30% sodium nitrite solution dropwise from the liquid surface to the above solution to prepare the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com