A kind of up-conversion white light solid material and its application in generating white light

A solid material, white light technology, used in luminescent materials, energy-saving lighting, sustainable buildings and other directions, can solve the problems of high photon quantum yield, low excitation energy, low luminous efficiency, etc., to reduce the amount of blue light radiation, low excitation power, The effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

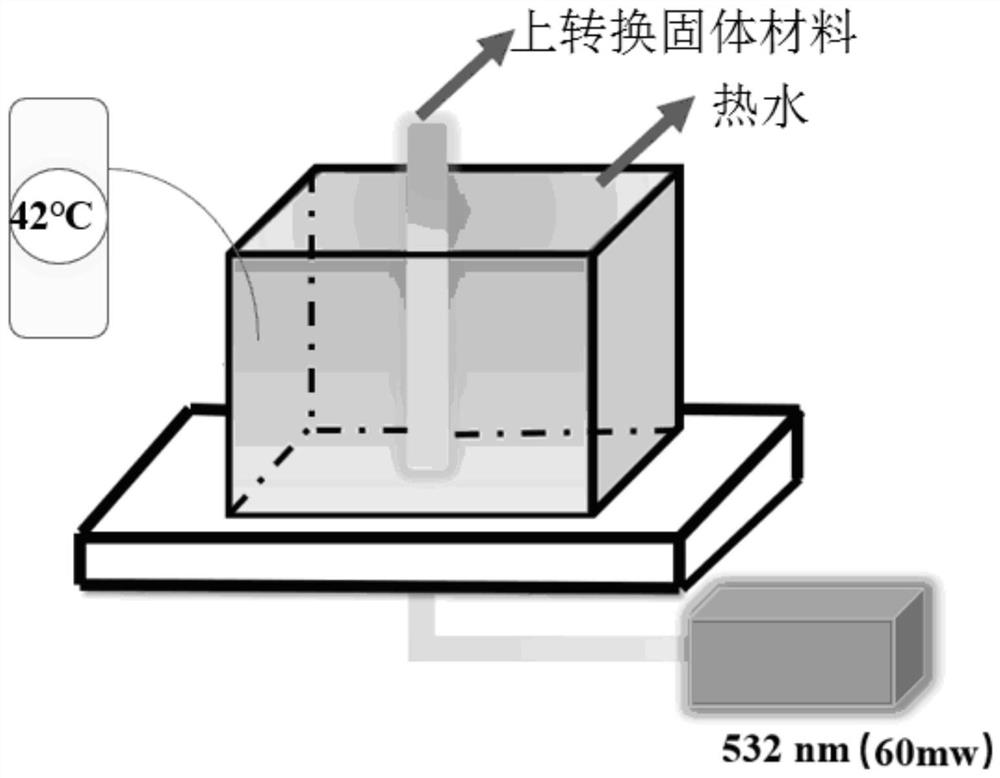

[0037] The photosensitizer used in the up-conversion solution in this example is palladium octaethylporphyrin (PdOEP), and the luminescent agent is 9,10-diphenylanthracene (DPA). The structures of the two are as follows:

[0038]

[0039] Preparation of upconverting microemulsion: In a nitrogen atmosphere, add Tween-20 to deionized water and stir evenly; then add toluene solution containing luminescent agent and photosensitizer, stir until completely clear to obtain weak light frequency upconverting microemulsion Emulsion system, at this time, irradiated with green light to obtain diffuse white light, the intensity is only 26cad, and it disappears in three seconds; the mass ratio of the toluene solution containing the luminescent agent and the photosensitizer, deionized water, and Tween-20 is 1: 10:5, the molar concentration ratio of photosensitizer (PdOEP) to luminescent agent (DPA) is 200:1, and the concentration of luminescent agent is 1.5×10 -2 mol / L.

[0040]Take 1 g ...

Embodiment 2

[0044] The photosensitizer used in the up-conversion solution in this example is palladium octaethylporphyrin (PtOEP), and the luminescent agent is 9,10-diphenylanthracene (DPA). The structures of the two are as follows:

[0045]

[0046] The preparation method of the low-light frequency up-conversion microemulsion system in this example is the same as that in Example 1, except that the photosensitizer is replaced by PtOEP.

[0047] Take 1g of low-light frequency up-conversion microemulsion system, add 2g of methacrylic acid, and then add 0.01g of benzoyl peroxide, stir evenly, and carry out polymerization reaction at 80°C to obtain a solid up-conversion material, which is an up-conversion white light solid Material.

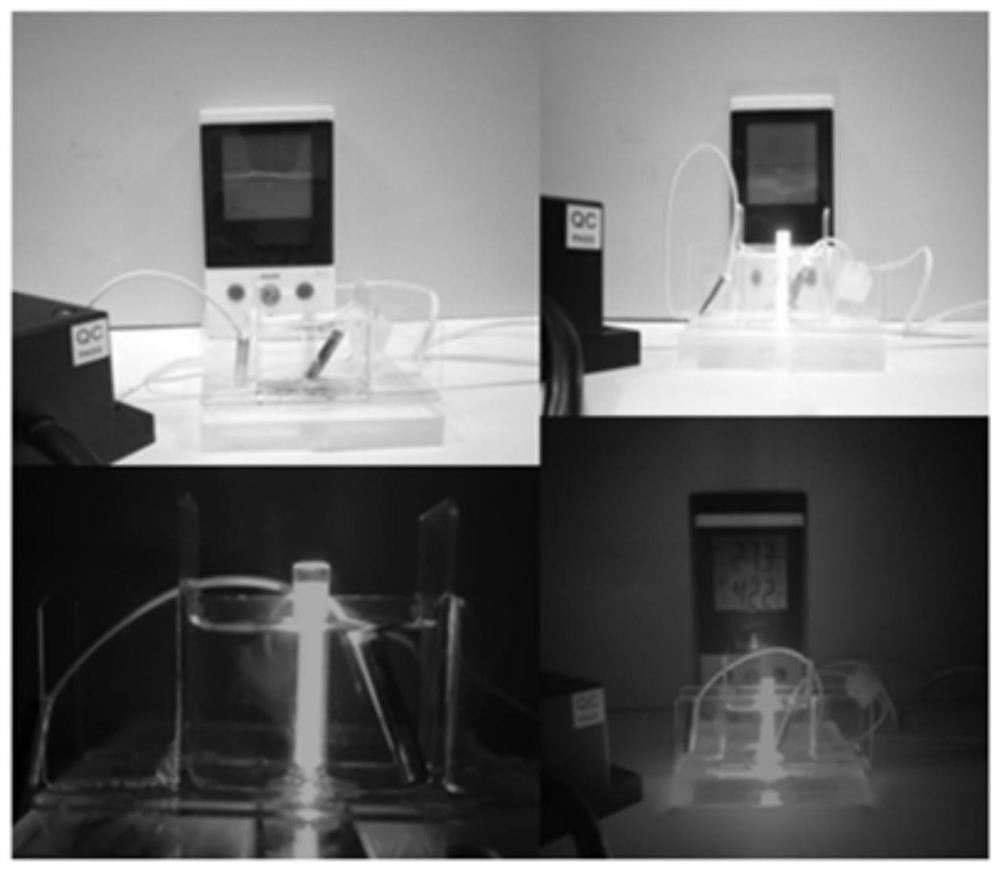

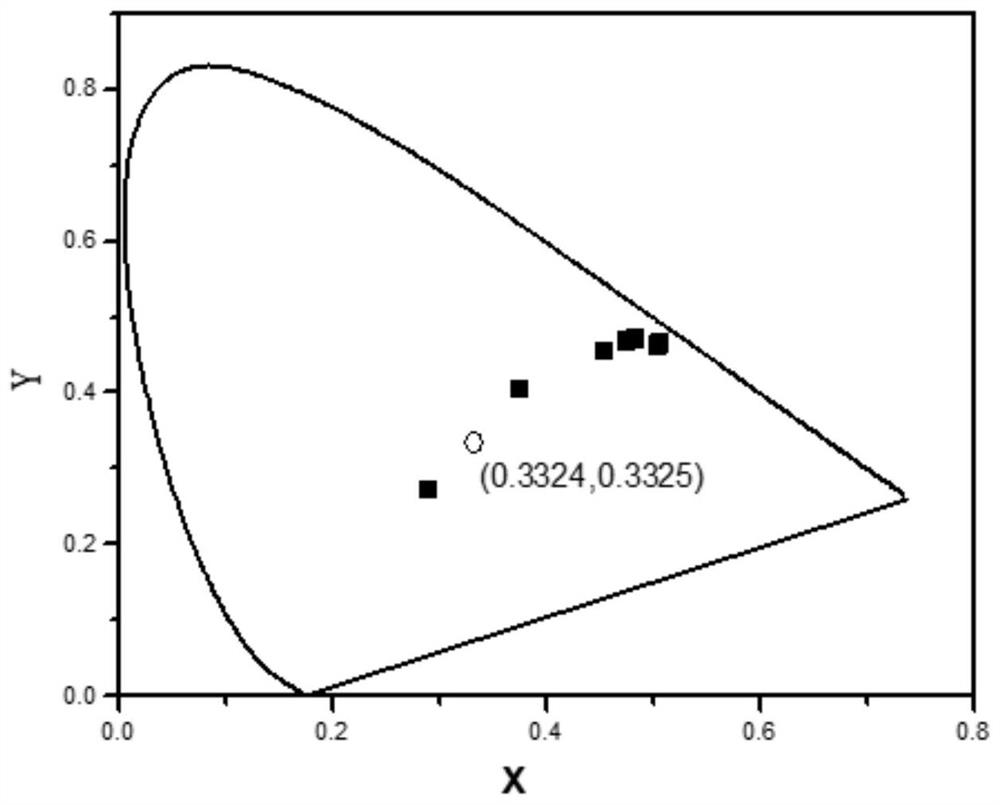

[0048] Use 532nm green light to excite (37.12mW) solid-state up-conversion material. When the temperature is 25°C, when the temperature is 30°C, the combination of three colors of light produces cool white light. The CIE coordinates of the white light point a...

Embodiment 3

[0050] In this example, the photosensitizer used in the up-conversion solution is palladium octaethylporphyrin (PdOEP), and the luminescent agent is anthracene (An). The structures of the two are as follows:

[0051]

[0052] The preparation method of the low-light frequency up-converting microemulsion system in this example is the same as Example 1, only the luminescent agent is replaced with An.

[0053] Take 1g of low-light frequency upconversion microemulsion system, add 4g of acrylamide, and then add 0.01g of benzoyl peroxide, stir evenly, carry out polymerization reaction at 80°C, and obtain solid upconversion material.

[0054] The solid-state up-conversion material is excited by 532nm green light (37.12mW). When the temperature is 20°C, the light combination of the three colors presents a partial white light. The CIE coordinates of the white light point are (0.352, 0.371), of which the red light radiation accounts for 74 %, green light radiation accounts for 10%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com